MAINTENANCE/SERVICE

FIGURE 49

8)Apply the installation lubricant to the exterior surface of the elastomeric mount to minimize damage when pressing into the mounting disc. If the factory supplied lubricant is not available, an acceptable alternative is the use of common liquid soap.

![]() CAUTION

CAUTION

Do not install an elastomeric mount without the use of an approved lubricant. Installation without an approved lubricant can produce tears in the mount, resulting in substandard operational performance and service life.

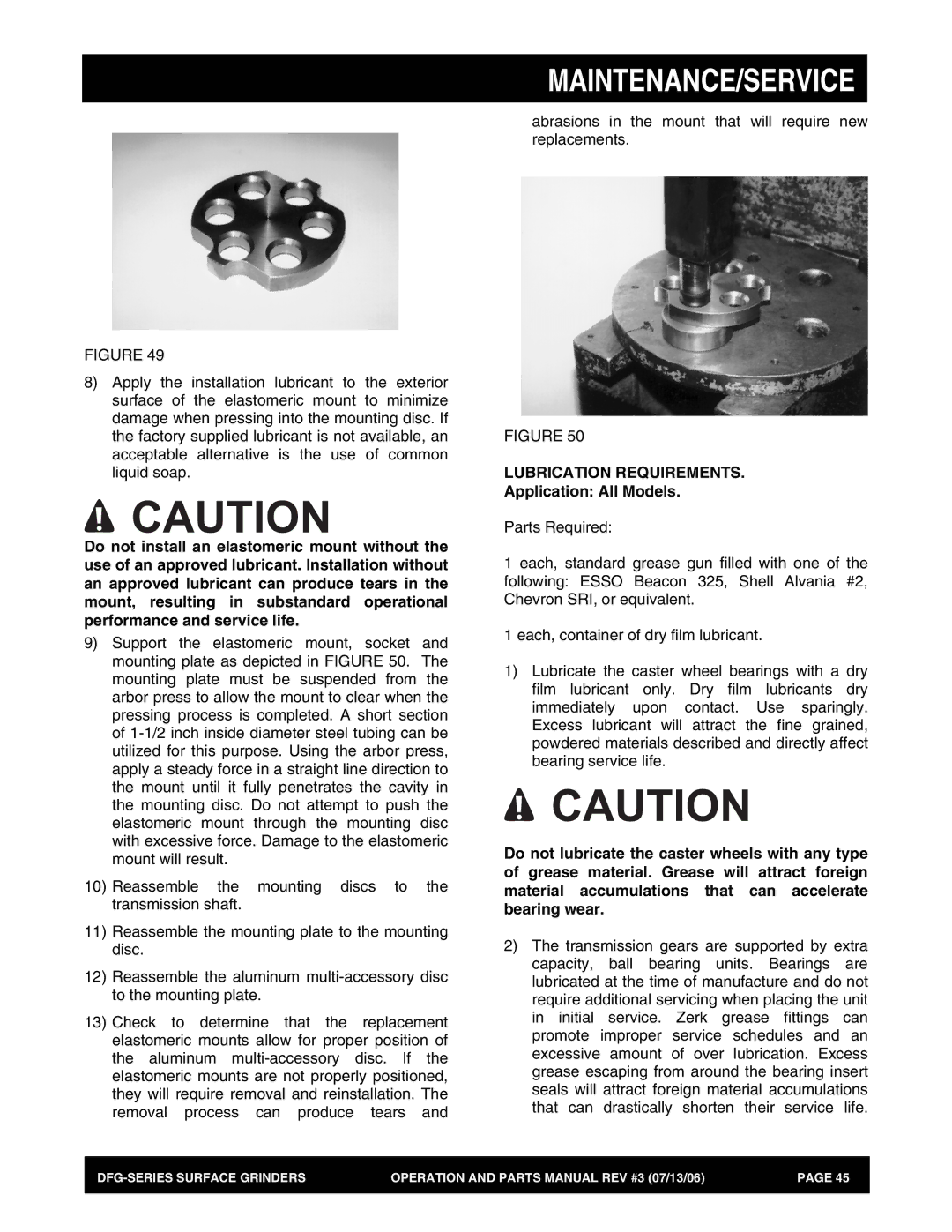

9)Support the elastomeric mount, socket and mounting plate as depicted in FIGURE 50. The mounting plate must be suspended from the arbor press to allow the mount to clear when the pressing process is completed. A short section of

10)Reassemble the mounting discs to the transmission shaft.

11)Reassemble the mounting plate to the mounting disc.

12)Reassemble the aluminum

13)Check to determine that the replacement elastomeric mounts allow for proper position of the aluminum

abrasions in the mount that will require new replacements.

FIGURE 50

LUBRICATION REQUIREMENTS.

Application: All Models.

Parts Required:

1 each, standard grease gun filled with one of the following: ESSO Beacon 325, Shell Alvania #2, Chevron SRI, or equivalent.

1 each, container of dry film lubricant.

1)Lubricate the caster wheel bearings with a dry film lubricant only. Dry film lubricants dry immediately upon contact. Use sparingly. Excess lubricant will attract the fine grained, powdered materials described and directly affect bearing service life.

![]() CAUTION

CAUTION

Do not lubricate the caster wheels with any type of grease material. Grease will attract foreign material accumulations that can accelerate bearing wear.

2)The transmission gears are supported by extra capacity, ball bearing units. Bearings are lubricated at the time of manufacture and do not require additional servicing when placing the unit in initial service. Zerk grease fittings can promote improper service schedules and an excessive amount of over lubrication. Excess grease escaping from around the bearing insert seals will attract foreign material accumulations that can drastically shorten their service life.

OPERATION AND PARTS MANUAL REV #3 (07/13/06) | PAGE 45 | |

|

|

|