NOTICE

The defrost thermostat delay will make the coil temperature about 75- 80° F. Please note that the timer will stop the circuit when R to Y is disconnected.

For instance, the X/L output will be energized with two flashes when defrost curve 2 is active. The control only reads the jumper input when the Y and W thermostat inputs are

Demand Defrost (13 Seer 1.5 ton, 14.5 Seer 1.5-4 Ton)

The control maintains proper airflow through the outdoor coil during heating operation by melting frost and ice that may form on the coil. Frost may accumulate unevenly in different sections of the coil because of the arrangement of the refrigeration circuit within the coil. The control may initiate a defrost cycle even when the coil is not completely cov- ered with frost. This is normal operation.

The control regulates the defrost operation of the heat pump based on accumulated compressor run time, outdoor coil temperature, and out- door ambient temperature. The control will cause the unit to operate in the normal heating mode until it determines that a defrost cycle is needed.

All defrost timings are based on accumulated compressor run time.

Operation

The defrost mode is equivalent to the cooling mode except that the out- door fan motor is

•

•Energize the reversing valve.

•Energize the auxiliary heat output through the W1/66 terminal.

•Begin the maximum defrost cycle length timer.

If the call for heating (Y) is removed from the control during the defrost cycle, it will terminate the defrost cycle and

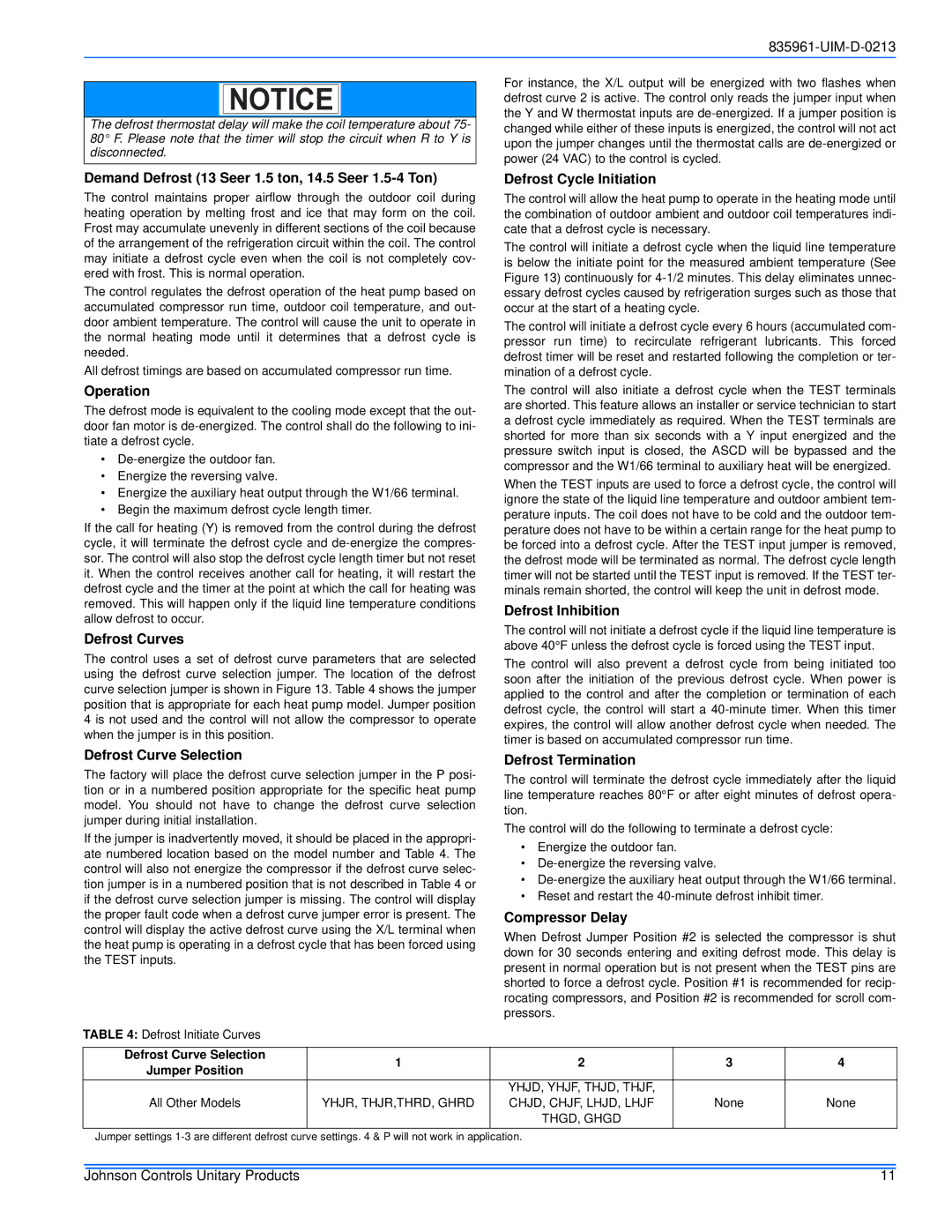

Defrost Curves

The control uses a set of defrost curve parameters that are selected using the defrost curve selection jumper. The location of the defrost curve selection jumper is shown in Figure 13. Table 4 shows the jumper position that is appropriate for each heat pump model. Jumper position 4 is not used and the control will not allow the compressor to operate when the jumper is in this position.

Defrost Curve Selection

The factory will place the defrost curve selection jumper in the P posi- tion or in a numbered position appropriate for the specific heat pump model. You should not have to change the defrost curve selection jumper during initial installation.

If the jumper is inadvertently moved, it should be placed in the appropri- ate numbered location based on the model number and Table 4. The control will also not energize the compressor if the defrost curve selec- tion jumper is in a numbered position that is not described in Table 4 or if the defrost curve selection jumper is missing. The control will display the proper fault code when a defrost curve jumper error is present. The control will display the active defrost curve using the X/L terminal when the heat pump is operating in a defrost cycle that has been forced using the TEST inputs.

TABLE 4: Defrost Initiate Curves

Defrost Cycle Initiation

The control will allow the heat pump to operate in the heating mode until the combination of outdoor ambient and outdoor coil temperatures indi- cate that a defrost cycle is necessary.

The control will initiate a defrost cycle when the liquid line temperature is below the initiate point for the measured ambient temperature (See Figure 13) continuously for

The control will initiate a defrost cycle every 6 hours (accumulated com- pressor run time) to recirculate refrigerant lubricants. This forced defrost timer will be reset and restarted following the completion or ter- mination of a defrost cycle.

The control will also initiate a defrost cycle when the TEST terminals are shorted. This feature allows an installer or service technician to start a defrost cycle immediately as required. When the TEST terminals are shorted for more than six seconds with a Y input energized and the pressure switch input is closed, the ASCD will be bypassed and the compressor and the W1/66 terminal to auxiliary heat will be energized.

When the TEST inputs are used to force a defrost cycle, the control will ignore the state of the liquid line temperature and outdoor ambient tem- perature inputs. The coil does not have to be cold and the outdoor tem- perature does not have to be within a certain range for the heat pump to be forced into a defrost cycle. After the TEST input jumper is removed, the defrost mode will be terminated as normal. The defrost cycle length timer will not be started until the TEST input is removed. If the TEST ter- minals remain shorted, the control will keep the unit in defrost mode.

Defrost Inhibition

The control will not initiate a defrost cycle if the liquid line temperature is above 40°F unless the defrost cycle is forced using the TEST input.

The control will also prevent a defrost cycle from being initiated too soon after the initiation of the previous defrost cycle. When power is applied to the control and after the completion or termination of each defrost cycle, the control will start a

Defrost Termination

The control will terminate the defrost cycle immediately after the liquid line temperature reaches 80°F or after eight minutes of defrost opera- tion.

The control will do the following to terminate a defrost cycle:

•Energize the outdoor fan.

•

•

•Reset and restart the

Compressor Delay

When Defrost Jumper Position #2 is selected the compressor is shut down for 30 seconds entering and exiting defrost mode. This delay is present in normal operation but is not present when the TEST pins are shorted to force a defrost cycle. Position #1 is recommended for recip- rocating compressors, and Position #2 is recommended for scroll com- pressors.

Defrost Curve Selection | 1 | 2 | 3 | 4 | |

Jumper Position | |||||

|

|

|

| ||

|

| YHJD, YHJF, THJD, THJF, |

|

| |

All Other Models | YHJR, THJR,THRD, GHRD | CHJD, CHJF, LHJD, LHJF | None | None | |

|

| THGD, GHGD |

|

|

Jumper settings

Johnson Controls Unitary Products | 11 |