SECTION IV: ORIFICE INSTALLATION

Failure to install Schrader Valve Core on orifice applications could result in total refrigerant loss of the system!

Install Schrader Valve Core and Orifice as follows:

1.Relieve the holding charge by depressing the Schrader valve stem located in the end of the liquid line. Cut the spundown copper to allow installation of the suction line.

2.Slide indoor coil out of cabinet far enough to gain access to equal- izer fitting on the suction line.

3.After holding charge is completely discharged remove black plastic cap on equalizer fitting.

4.Install Schrader Valve Core supplied with the outdoor unit into equal- izer fitting using a valve core tool.

5.Loosen and remove the liquid line fitting from the orifice distributor assembly. Note that the fitting has right hand threads.

6.Install proper size orifice supplied with outdoor unit. Refer to sup- plied Tabular Data Sheet for specific orifice size and indoor coil match up.

7.After orifice is installed reinstall the liquid line to the top of the orifice distributor assembly. Hand tighten and turn an additional 1/8 turn to seal. Do not over tighten fittings.

8.Leak test system.

9.Replace black plastic cap on equalizer fitting.

10.Slide indoor coil back into cabinet.

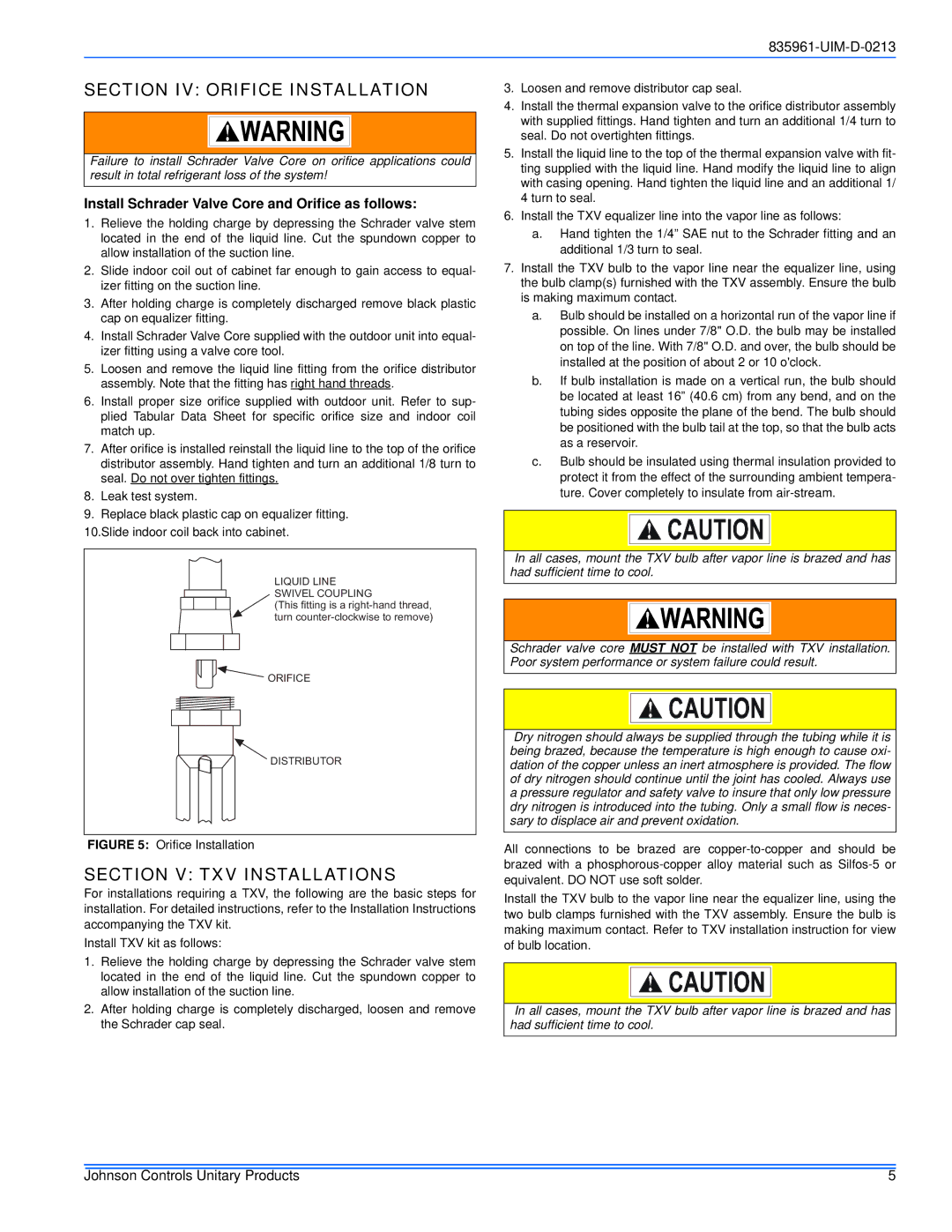

LIQUID LINE SWIVEL COUPLING

(This fitting is a

ORIFICE

DISTRIBUTOR

FIGURE 5: Orifice Installation

SECTION V: TXV INSTALLATIONS

For installations requiring a TXV, the following are the basic steps for installation. For detailed instructions, refer to the Installation Instructions accompanying the TXV kit.

Install TXV kit as follows:

1.Relieve the holding charge by depressing the Schrader valve stem located in the end of the liquid line. Cut the spundown copper to allow installation of the suction line.

2.After holding charge is completely discharged, loosen and remove the Schrader cap seal.

3.Loosen and remove distributor cap seal.

4.Install the thermal expansion valve to the orifice distributor assembly with supplied fittings. Hand tighten and turn an additional 1/4 turn to seal. Do not overtighten fittings.

5.Install the liquid line to the top of the thermal expansion valve with fit- ting supplied with the liquid line. Hand modify the liquid line to align with casing opening. Hand tighten the liquid line and an additional 1/ 4 turn to seal.

6.Install the TXV equalizer line into the vapor line as follows:

a.Hand tighten the 1/4” SAE nut to the Schrader fitting and an additional 1/3 turn to seal.

7.Install the TXV bulb to the vapor line near the equalizer line, using the bulb clamp(s) furnished with the TXV assembly. Ensure the bulb is making maximum contact.

a.Bulb should be installed on a horizontal run of the vapor line if possible. On lines under 7/8" O.D. the bulb may be installed on top of the line. With 7/8" O.D. and over, the bulb should be installed at the position of about 2 or 10 o'clock.

b.If bulb installation is made on a vertical run, the bulb should be located at least 16” (40.6 cm) from any bend, and on the tubing sides opposite the plane of the bend. The bulb should be positioned with the bulb tail at the top, so that the bulb acts as a reservoir.

c.Bulb should be insulated using thermal insulation provided to protect it from the effect of the surrounding ambient tempera- ture. Cover completely to insulate from

In all cases, mount the TXV bulb after vapor line is brazed and has had sufficient time to cool.

Schrader valve core MUST NOT be installed with TXV installation. Poor system performance or system failure could result.

Dry nitrogen should always be supplied through the tubing while it is being brazed, because the temperature is high enough to cause oxi- dation of the copper unless an inert atmosphere is provided. The flow of dry nitrogen should continue until the joint has cooled. Always use a pressure regulator and safety valve to insure that only low pressure dry nitrogen is introduced into the tubing. Only a small flow is neces- sary to displace air and prevent oxidation.

All connections to be brazed are

Install the TXV bulb to the vapor line near the equalizer line, using the two bulb clamps furnished with the TXV assembly. Ensure the bulb is making maximum contact. Refer to TXV installation instruction for view of bulb location.

In all cases, mount the TXV bulb after vapor line is brazed and has had sufficient time to cool.

Johnson Controls Unitary Products | 5 |