Requirements For Installing/Servicing R-410A Equipment

•Gauge sets, hoses, refrigerant containers, and recovery system must be designed to handle the POE type oils, and the higher pressures of

•Manifold sets should be 800 psig high side and 250 psig low side with 550 psig low side restart.

•All hoses must have a 700 psig service pressure rating.

•Leak detectors should be designed to detect HFC refrigerant.

•Recovery equipment (including refrigerant recovery containers) must be specifically designed to handle

•Do not use an

•A

LIMITATIONS

The unit should be installed in accordance with all National, State, and Local Safety Codes and the limitations listed below:

1.Limitations for the indoor unit, coil, and appropriate accessories must also be observed.

2.The outdoor unit must not be installed with any duct work in the air stream. The outdoor fan is the propeller type and is not designed to operate against any additional external static pressure.

3.The maximum and minimum conditions for operation must be observed to assure a system that will give maximum performance with minimum service.

4.The maximum allowable line length for this product is 75 feet.

AIR TEMPERATURE AT | AIR TEMPERATURE AT | ||||||||||

| OUTDOOR COIL, °F |

|

| INDOOR COIL, °F |

| ||||||

|

|

|

| ||||||||

Min. | Max. | Min. | Max. | ||||||||

DB |

| DB | DB |

| DB | WB |

| DB | WB |

| DB |

Cool |

| Heat | Cool |

| Heat | Cool |

| Heat | Cool |

| Heat |

|

|

|

|

|

|

|

|

|

|

|

|

50 |

| 115 |

| 75 | 57 |

| 501 | 72 |

| 80 | |

1.Operation below this temperature is permissible for a short period of time, during morning

SECTION III: UNIT INSTALLATION

LOCATION

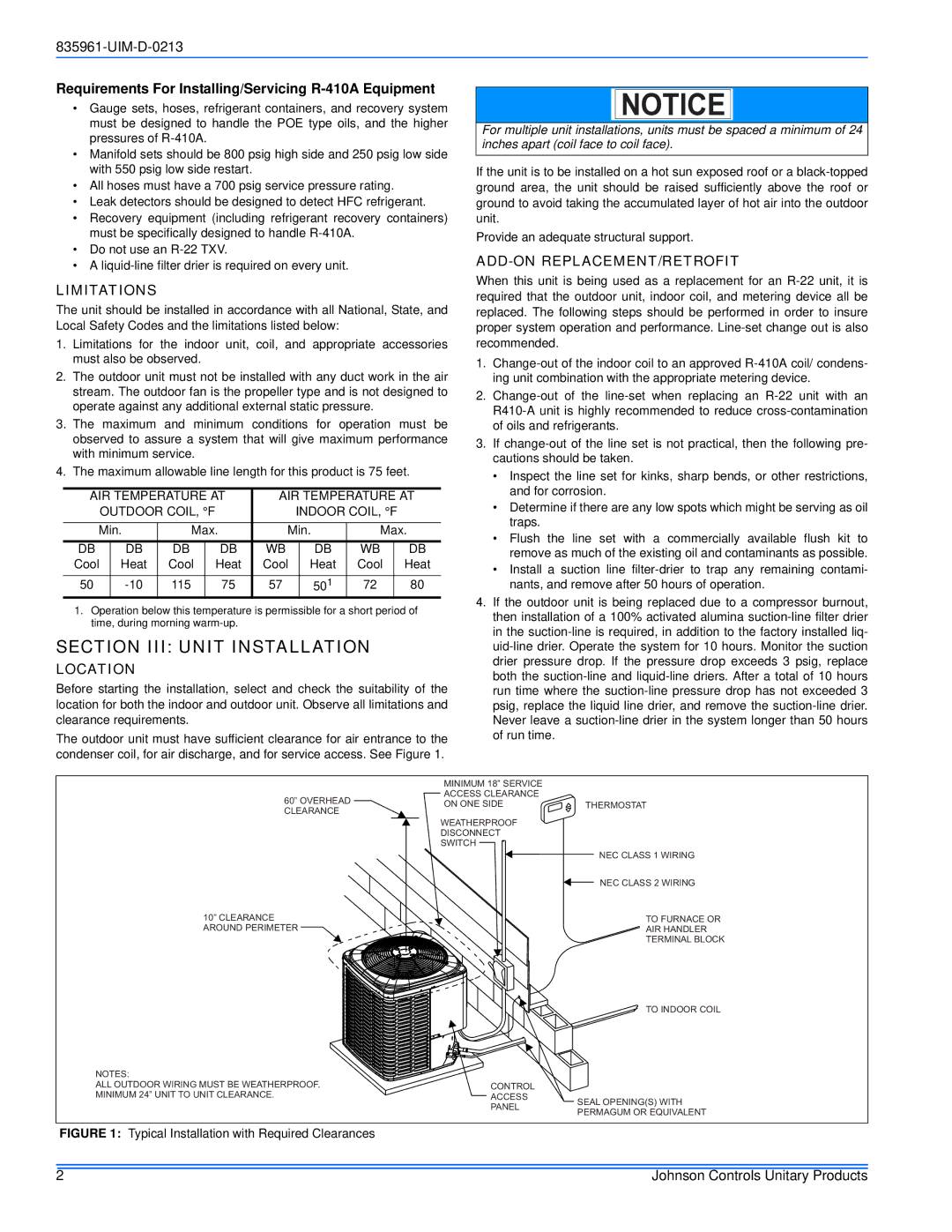

Before starting the installation, select and check the suitability of the location for both the indoor and outdoor unit. Observe all limitations and clearance requirements.

The outdoor unit must have sufficient clearance for air entrance to the condenser coil, for air discharge, and for service access. See Figure 1.

NOTICE

For multiple unit installations, units must be spaced a minimum of 24 inches apart (coil face to coil face).

If the unit is to be installed on a hot sun exposed roof or a

Provide an adequate structural support.

ADD-ON REPLACEMENT/RETROFIT

When this unit is being used as a replacement for an

1.

2.

3.If

•Inspect the line set for kinks, sharp bends, or other restrictions, and for corrosion.

•Determine if there are any low spots which might be serving as oil traps.

•Flush the line set with a commercially available flush kit to remove as much of the existing oil and contaminants as possible.

•Install a suction line

4.If the outdoor unit is being replaced due to a compressor burnout, then installation of a 100% activated alumina

60” OVERHEAD CLEARANCE

10” CLEARANCE AROUND PERIMETER ![]()

NOTES:

ALL OUTDOOR WIRING MUST BE WEATHERPROOF. MINIMUM 24” UNIT TO UNIT CLEARANCE.

MINIMUM 18” SERVICE ACCESS CLEARANCE ![]() ON ONE SIDE

ON ONE SIDE![]()

![]()

![]()

WEATHERPROOF

DISCONNECT

SWITCH

CONTROL

ACCESS

PANEL

THERMOSTAT

NEC CLASS 1 WIRING

NEC CLASS 2 WIRING

TO FURNACE OR

AIR HANDLER

TERMINAL BLOCK

TO INDOOR COIL

SEAL OPENING(S) WITH PERMAGUM OR EQUIVALENT

FIGURE 1: Typical Installation with Required Clearances

2 | Johnson Controls Unitary Products |