SECTION IX: SYSTEM START-UP

ENERGIZE CRANKCASE HEATER

If this unit is equipped with a crankcase heater for the compressor, a warning label with an adhesive back is supplied in the unit installation instruction packet. This label should be attached to the field supplied disconnect switch where it will be easily seen.

In order to energize the crankcase heater, set the indoor cooling ther- mostat to the OFF position. Close the line power disconnect to the unit.

An attempt to start the compressor without at least 8 hours of crank- case heat will damage the compressor.

WITH POWER TO UNIT AND THERMOSTAT IN COOLING POSITION:

1.In the cooling cycle, discharge gas is pumped to the outdoor coil which is the condenser. The indoor coil is the evaporator.

2.If fan switch is in ON position, a circuit is made through blower relay to provide continuous blower operation.

3.With fan switch in AUTO position, a circuit is made from thermostat cooling contact through blower relay to provide blower operation.

4.System will cycle with thermostat demand to provide cooling as needed.

TABLE 1:

Temp °F | Pressure | Temp °F | Pressure | Temp °F | Pressure | Temp °F | Pressure | Temp °F | Pressure | |

PSIG | PSIG | PSIG | PSIG | PSIG | ||||||

|

|

|

|

| ||||||

45 | 130 | 60 | 170 | 75 | 217 | 90 | 274 | 105 | 341 | |

46 | 132 | 61 | 173 | 76 | 221 | 91 | 278 | 106 | 345 | |

47 | 135 | 62 | 176 | 77 | 224 | 92 | 282 | 107 | 350 | |

48 | 137 | 63 | 179 | 78 | 228 | 93 | 287 | 108 | 355 | |

49 | 140 | 64 | 182 | 79 | 232 | 94 | 291 | 109 | 360 | |

50 | 142 | 65 | 185 | 80 | 235 | 95 | 295 | 110 | 365 | |

51 | 145 | 66 | 188 | 81 | 239 | 96 | 299 | 111 | 370 | |

52 | 147 | 67 | 191 | 82 | 243 | 97 | 304 | 112 | 375 | |

53 | 150 | 68 | 194 | 83 | 247 | 98 | 308 | 113 | 380 | |

54 | 153 | 69 | 197 | 84 | 250 | 99 | 313 | 114 | 385 | |

55 | 156 | 70 | 201 | 85 | 254 | 100 | 317 | 115 | 391 | |

56 | 158 | 71 | 204 | 86 | 258 | 101 | 322 | 116 | 396 | |

57 | 161 | 72 | 207 | 87 | 262 | 102 | 326. | 117 | 401 | |

58 | 164 | 73 | 211 | 88 | 266 | 103 | 331 | 118 | 407 | |

59 | 167 | 74 | 214 | 89 | 270 | 104 | 336 | 119 | 412 |

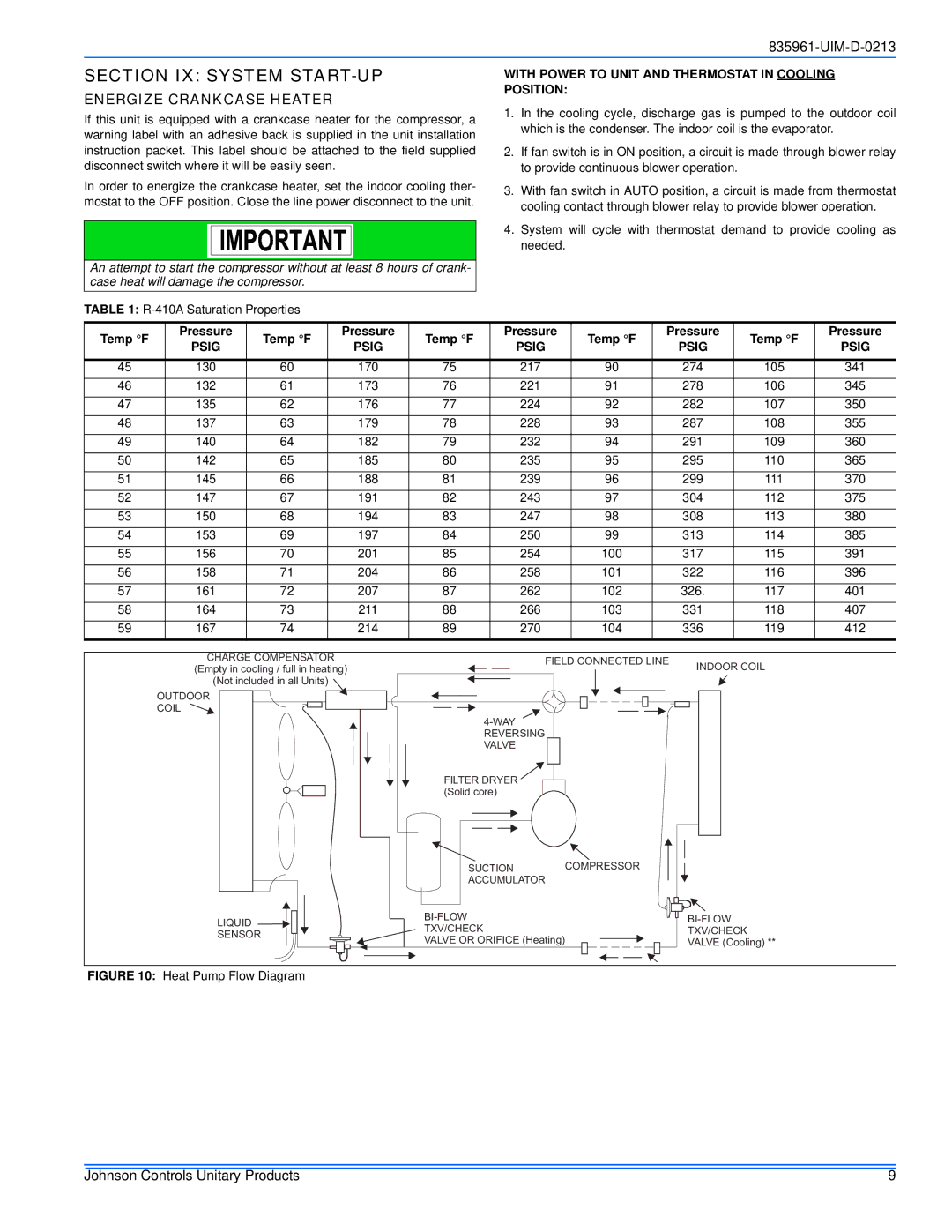

CHARGE COMPENSATOR

(Empty in cooling / full in heating)

(Not included in all Units)

OUTDOOR

COIL

FIELD CONNECTED LINE

FILTER DRYER (Solid core)

INDOOR COIL

LIQUID |

SENSOR |

SUCTION | COMPRESSOR |

|

|

| |

ACCUMULATOR |

|

|

| ||

TXV/CHECK |

| TXV/CHECK |

VALVE OR ORIFICE (Heating) | VALVE (Cooling) ** | |

FIGURE 10: Heat Pump Flow Diagram

Johnson Controls Unitary Products | 9 |