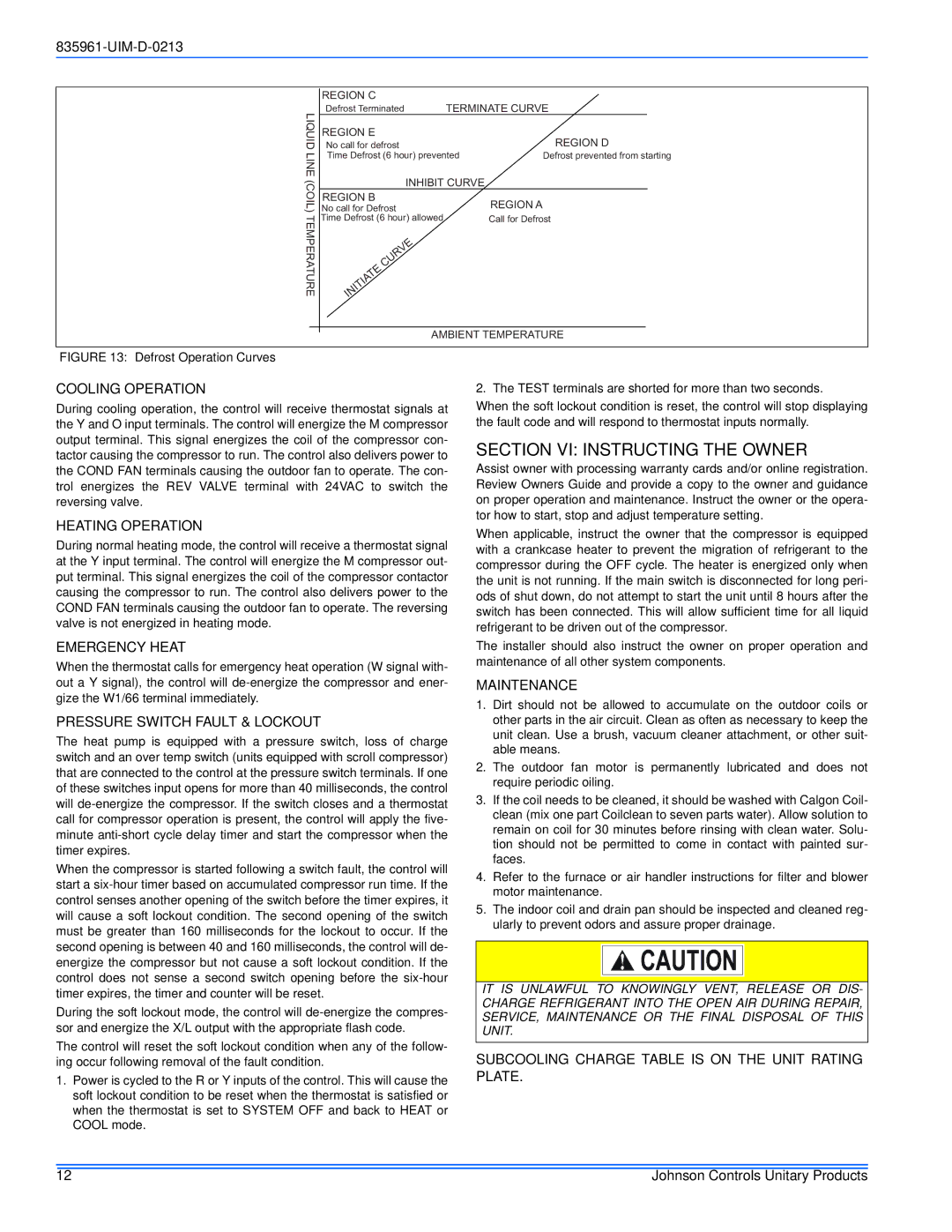

LIQUID LINE (COIL) TEMPERATURE

REGION C

Defrost Terminated | TERMINATE CURVE | ||

REGION E |

|

|

|

No call for defrost |

| REGION D | |

Time Defrost (6 hour) prevented | Defrost prevented from starting | ||

| INHIBIT CURVE |

|

|

REGION B |

| REGION A | |

No call for Defrost |

| ||

|

|

| |

Time Defrost (6 hour) allowed | Call for Defrost | ||

AMBIENT TEMPERATURE

FIGURE 13: Defrost Operation Curves

COOLING OPERATION

During cooling operation, the control will receive thermostat signals at the Y and O input terminals. The control will energize the M compressor output terminal. This signal energizes the coil of the compressor con- tactor causing the compressor to run. The control also delivers power to the COND FAN terminals causing the outdoor fan to operate. The con- trol energizes the REV VALVE terminal with 24VAC to switch the reversing valve.

HEATING OPERATION

During normal heating mode, the control will receive a thermostat signal at the Y input terminal. The control will energize the M compressor out- put terminal. This signal energizes the coil of the compressor contactor causing the compressor to run. The control also delivers power to the COND FAN terminals causing the outdoor fan to operate. The reversing valve is not energized in heating mode.

EMERGENCY HEAT

When the thermostat calls for emergency heat operation (W signal with- out a Y signal), the control will

PRESSURE SWITCH FAULT & LOCKOUT

The heat pump is equipped with a pressure switch, loss of charge switch and an over temp switch (units equipped with scroll compressor) that are connected to the control at the pressure switch terminals. If one of these switches input opens for more than 40 milliseconds, the control will

When the compressor is started following a switch fault, the control will start a

During the soft lockout mode, the control will

The control will reset the soft lockout condition when any of the follow- ing occur following removal of the fault condition.

1.Power is cycled to the R or Y inputs of the control. This will cause the soft lockout condition to be reset when the thermostat is satisfied or when the thermostat is set to SYSTEM OFF and back to HEAT or COOL mode.

2. The TEST terminals are shorted for more than two seconds.

When the soft lockout condition is reset, the control will stop displaying the fault code and will respond to thermostat inputs normally.

SECTION VI: INSTRUCTING THE OWNER

Assist owner with processing warranty cards and/or online registration. Review Owners Guide and provide a copy to the owner and guidance on proper operation and maintenance. Instruct the owner or the opera- tor how to start, stop and adjust temperature setting.

When applicable, instruct the owner that the compressor is equipped with a crankcase heater to prevent the migration of refrigerant to the compressor during the OFF cycle. The heater is energized only when the unit is not running. If the main switch is disconnected for long peri- ods of shut down, do not attempt to start the unit until 8 hours after the switch has been connected. This will allow sufficient time for all liquid refrigerant to be driven out of the compressor.

The installer should also instruct the owner on proper operation and maintenance of all other system components.

MAINTENANCE

1.Dirt should not be allowed to accumulate on the outdoor coils or other parts in the air circuit. Clean as often as necessary to keep the unit clean. Use a brush, vacuum cleaner attachment, or other suit- able means.

2.The outdoor fan motor is permanently lubricated and does not require periodic oiling.

3.If the coil needs to be cleaned, it should be washed with Calgon Coil- clean (mix one part Coilclean to seven parts water). Allow solution to remain on coil for 30 minutes before rinsing with clean water. Solu- tion should not be permitted to come in contact with painted sur- faces.

4.Refer to the furnace or air handler instructions for filter and blower motor maintenance.

5.The indoor coil and drain pan should be inspected and cleaned reg- ularly to prevent odors and assure proper drainage.

IT IS UNLAWFUL TO KNOWINGLY VENT, RELEASE OR DIS- CHARGE REFRIGERANT INTO THE OPEN AIR DURING REPAIR, SERVICE, MAINTENANCE OR THE FINAL DISPOSAL OF THIS UNIT.

SUBCOOLING CHARGE TABLE IS ON THE UNIT RATING PLATE.

12 | Johnson Controls Unitary Products |