ALL FIELD WIRING TO BE IN ACCORDANCE WITH ELECTRIC CODE (NEC) AND/OR LOCAL CODES

THERMOSTAT | INDOOR UNIT | OUTDOOR UNIT |

R

B or![]()

![]() C

C

Y

O

W

L or X

G

T2

E2

1FIELD INSTALLED JUMPER

LOW VOLTAGE TERMINAL BLOCK 3,4 | DEFROST | |||||||||

IN AIR HANDLER WITH ELECTRIC HEAT | CONTROL | |||||||||

|

|

|

|

| RED |

|

|

|

| |

| R |

|

| R |

|

| ||||

|

|

| BLK |

|

|

| ||||

|

|

|

|

|

|

|

|

|

| |

| B | or C |

| C |

|

| ||||

|

|

|

|

| ||||||

| Y |

|

| YEL |

|

|

|

| ||

|

|

| Y |

|

| |||||

|

|

| ORG |

|

| |||||

| O |

|

|

|

|

|

| |||

|

|

| O |

|

| |||||

|

|

| WHT |

|

|

| ||||

| W2 |

|

|

|

|

|

|

| ||

|

|

|

| W |

|

| ||||

|

|

|

|

|

|

| ||||

|

|

|

|

| PUR |

|

|

|

| |

|

|

|

|

| X |

|

| |||

|

|

|

|

|

|

|

|

| ||

| G |

|

| BRN | W | 1/ | 66 | |||

|

|

|

|

| ||||||

| W1 |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

CONTACTOR

T3 T2 T1

M

GND.

L3 L2 L1 SCREW

1JUMPER TERMINALS E AND W TO HEAT

ON FIRST STAGE DURING EMERGENCY HEAT.

2TERMINAL NOT USED ON ALL THERMOSTATS.

POWER WIRING

24V CONTROL WIRING (NEC CLASS 2)

| POWER | |

| SUPPLY | |

GND. | ||

LUG | ||

|

POWER WIRING

3 CHECK THE LOW VOLTAGE TERMINAL BLOCK ON THE INDOOR UNIT FOR THE ACTUAL ARRANGEMENT OF THE TERMINALS.

4CONNECT POWER WIRING TO TERMINAL BLOCK 3TB ON UNITS WITHOUT ELECTRIC HEAT OR CIRCUIT BREAKER.

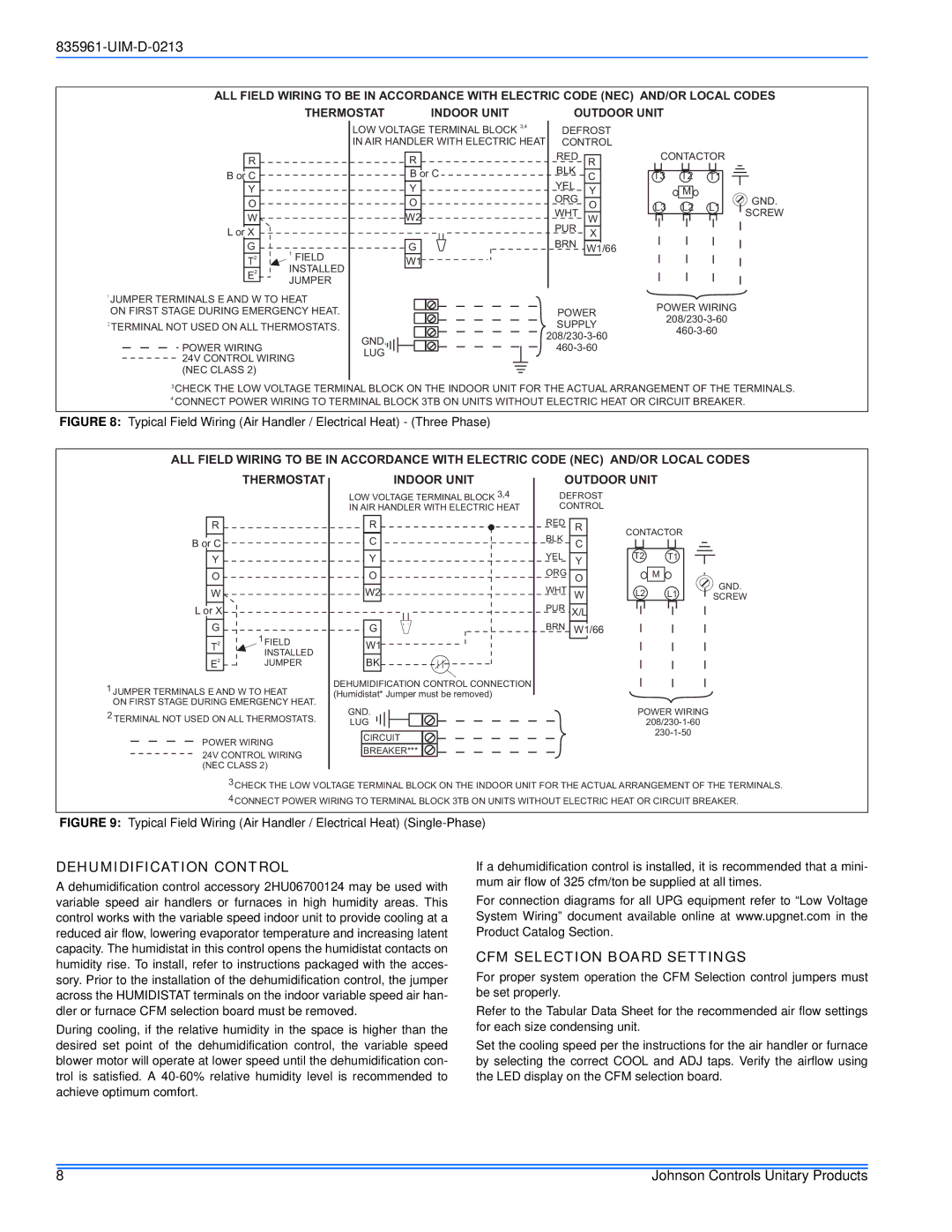

FIGURE 8: Typical Field Wiring (Air Handler / Electrical Heat) - (Three Phase)

ALL FIELD WIRING TO BE IN ACCORDANCE WITH ELECTRIC CODE (NEC) AND/OR LOCAL CODES

THERMOSTAT

INDOOR UNIT

LOW VOLTAGE TERMINAL BLOCK 3,4 IN AIR HANDLER WITH ELECTRIC HEAT

OUTDOOR UNIT

DEFROST

CONTROL

R

B or C

Y

O

W

L or X

G

T2

E2

1FIELD INSTALLED JUMPER

R

C

Y

O

W2

G![]()

W1

BK ![]()

![]()

![]()

RED | R |

|

|

| CONTACTOR | ||

BLK |

| ||

C |

|

| |

|

|

| |

YEL | Y | T2 | T1 |

|

|

| |

ORG | O |

| M |

WHT | W | L2 | L1 |

PUR X/L |

|

| |

BRN | W1/66 |

|

|

|

|

| |

GND.

SCREW

1JUMPER TERMINALS E AND W TO HEAT

ON FIRST STAGE DURING EMERGENCY HEAT.

2 TERMINAL NOT USED ON ALL THERMOSTATS.

POWER WIRING

24V CONTROL WIRING (NEC CLASS 2)

DEHUMIDIFICATION CONTROL CONNECTION (Humidistat* Jumper must be removed)

GND.

LUG

CIRCUIT

BREAKER***

POWER WIRING

3CHECK THE LOW VOLTAGE TERMINAL BLOCK ON THE INDOOR UNIT FOR THE ACTUAL ARRANGEMENT OF THE TERMINALS.

4CONNECT POWER WIRING TO TERMINAL BLOCK 3TB ON UNITS WITHOUT ELECTRIC HEAT OR CIRCUIT BREAKER.

FIGURE 9: Typical Field Wiring (Air Handler / Electrical Heat) (Single-Phase)

DEHUMIDIFICATION CONTROL

A dehumidification control accessory 2HU06700124 may be used with variable speed air handlers or furnaces in high humidity areas. This control works with the variable speed indoor unit to provide cooling at a reduced air flow, lowering evaporator temperature and increasing latent capacity. The humidistat in this control opens the humidistat contacts on humidity rise. To install, refer to instructions packaged with the acces- sory. Prior to the installation of the dehumidification control, the jumper across the HUMIDISTAT terminals on the indoor variable speed air han- dler or furnace CFM selection board must be removed.

During cooling, if the relative humidity in the space is higher than the desired set point of the dehumidification control, the variable speed blower motor will operate at lower speed until the dehumidification con- trol is satisfied. A

If a dehumidification control is installed, it is recommended that a mini- mum air flow of 325 cfm/ton be supplied at all times.

For connection diagrams for all UPG equipment refer to “Low Voltage System Wiring” document available online at www.upgnet.com in the Product Catalog Section.

CFM SELECTION BOARD SETTINGS

For proper system operation the CFM Selection control jumpers must be set properly.

Refer to the Tabular Data Sheet for the recommended air flow settings for each size condensing unit.

Set the cooling speed per the instructions for the air handler or furnace by selecting the correct COOL and ADJ taps. Verify the airflow using the LED display on the CFM selection board.

8 | Johnson Controls Unitary Products |