Tiger Corporation

3301 N. Louise Ave Sioux Falls, SD

06010005

PARTS LISTING WITH MOUNTING AND OPERATING INSTRUCTIONS

TO THE OWNER / OPERATOR / DEALER

FORWARD

Tiger Corporation

Page

TABLE OF CONTENTS

CAUTION - YOUR SAFETY IS AT RISK

This symbol means

ASSEMBLY / MOUNTING SECTION

Page

SAFETY SECTION

SAFETY

General Safety Instructions and Practices

Practice all usual and customary safe working precautions and

SAFETY

SAFETY

LEA EL INSTRUCTIVO

DANGER

SAFETY

SG-10

SG-11

SG-12

SAFETY

sure you abide by the following rules

SAFETY

DANGER DANGER

SG-20

SG-23

SAFETY

SGM-1

SAFETY

contact such items. SGM-6

SAFETY

STOP MOWING IF PASSERSBY ARE WITHIN 100 YARDS UN- LESS

“Wait a minute...Save a life!”

SBM-2

SAFETY

work. SBM-6

SBM-7

SEE YOUR

DEALER

SAFETY

In addition to the design and configuration of this Implement, including Safety Signs and Safety Equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also to Safety Messages and operation instruction in each of the appropriate sections of the Tractor and Equipment Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment. SG-18

SAFETY

DESCRIPTION

33514

AVAIL

SAFETY

ROTARY DECK DECALS

SAFETY

WARNING, DO NOT REMOVE SHIELD

SAFETY

Cheetah Safety Section

002369 00725746 00769737

SAFETY

Cheetah Safety Section

02962764 02962765 02965262

SAFETY

Cheetah Safety Section

02971123 03200285 22645 22839

SAFETY

Cheetah Safety Section

22840 24028 25387

SAFETY

Cheetah Safety Section

32707 32708 32709

SAFETY

Cheetah Safety Section

33224 33302 33435

SAFETY

Cheetah Safety Section

33436 33437 33438 42350 RED42399

SAFETY

Cheetah Safety Section

AMBER42400 6T3217 6T3219 6T3220 6T3221

SAFETY

Cheetah Safety Section

6T3222 6T3224 6T3225 6T3230 6T3233

SAFETY

Cheetah Safety Section

6T3234 6T3236 6T3237 34206

SAFETY

Cheetah Safety Section

6T3243 TB1011 33743

SAFETY

34852 HYDRAULIC TANK

SAFETY

DRILLING HOLES INTO UNKNOWN AREAS, wires and other parts may

DESCRIPTION

50023

SAFETY FEDERAL LAWS AND REGULATIONS

Employer-Employee Operator Regulations

This Act Seeks

DUTIES

ASSEMBLY SECTION

Assembly Section

ASSEMBLY

TRACTOR PREPARATION

CRANKSHAFT ADAPTER

ASSEMBLY POLYCARBONATE SAFETY WINDOW

ADJUSTING REAR WHEELS

MAIN FRAME MOUNTING

ASSEMBLY AXLE BRACE

3-POINT BOOM REST MOUNTING

ASSEMBLY JOYSTICK SWITCH BOX MOUNTING

ASSEMBLY JOYSTICK SWITCH BOX WIRING

ASSEMBLY JOYSTICK CONTROL MOUNTING

VALVE MOUNTING

CAB POST BOLTS

ASSEMBLY DANFOSS VALVE PLUMBING SCV ONLY UNITS

SELECTIVE CONTROL VALVE SCV

ASSEMBLY DANFOSS VALVE PLUMBING WITH MID-MOUNT VALVE

MID-MOUNT VALVE

ASSEMBLY HUSCO VALVE PLUMBING SCV ONLY UNITS

SELECTIVE CONTROL VALVE SCV

ASSEMBLY HUSCO VALVE PLUMBING WITH MID-MOUNT VALVE

MID-MOUNT VALVE

ASSEMBLY CABLE CONTROL LEVER STAND SCV ONLY UNITS

ASSEMBLY CABLE CONTROL LEVER STAND MID-MOUNT UNITS

WINDOW ROUTING

ASSEMBLY HOSE AND CABLE ROUTING

FIRST HOLE

SECOND HOLE

ASSEMBLY

Assembly Section

ASSEMBLY CHEETAH HOSE ROUTING

ASSEMBLY

Arrange the hoses in the clamp that attaches to the boom mounting bracket as shown above, with the 1” motor hoses closest to the bracket and the return hose closest to the boom arm. Pull the hoses snug from the swivel to the mounting bracket clamps, when main boom is still forward, and tighten the hoses in the clamp

ASSEMBLY HYDRAULIC TANK INSTALLATION

GENERAL HOSE INSTALLATION

SWIVEL BRACKET MOUNTING

ASSEMBLY PREFORMED TUBE INSTALLATION

BOOM INSTALLATION

DECK ATTACHMENT

HOSE COVERING

ASSEMBLY INSTALLING O-RING FITTINGS

INSTALLING NATIONAL PIPE FITTINGS

ACCUMULATOR INSTALLATION / PLUMBING

WHEEL WEIGHT MOUNTING

ASSEMBLY BOOM JOYSTICK CONTROL CALIBRATION

SUB-D

ASSEMBLY

Setting Signal Adaptation Potentiometers

Set the dead band compensation potentiometer first

ASSEMBLY

MAIN BOOM “A” Port, Boom UP 7-9 Seconds

“B” Port, Boom Down 6-8 Seconds

SECONDARY

ASSEMBLY

Assembly Section

ASSEMBLY FINAL PREPARATION FOR OPERATION

MOWER TESTING

ASSEMBLY 4WD FRONT TIRE ADJUSTMENT

OPERATION SECTION

OPERATION

OPERATION

STARTING TRACTOR AND MOWER

OPERATION

OPERATION JOYSTICK CONTROL SWITCH BOX

SAFETY SHIELD MOWER RUNSWITCH INDICATOR LIGHT TRAVEL LOCK

MOWER CONTROL SWITCH SWITCH

SWITCH

Note Pushing manual valve handles “out” or “away” from the tractor cab will bring the main boom “up”, secondary boom “out”, roll deck “out”, and swivel boom “aft”. Pulling manual handles toward cab will let main boom “down”, bring secondary boom “in”, roll deck “in”, swivel boom “forward”, and close the safety shield

OPERATION

OPERATION JOYSTICK CONTROL

RIGHT JOYSTICK ROLLER MOVES BOOM SWIVEL SHIELD SWITCH

OPERATES SAFETY SHIELD

OPERATION JOYSTICK FWD / BACK MOVES MAIN BOOM JOYSTICK LEFT / RIGHT

MOVES SECONDARY BOOM LEFT JOYSTICK ROLLER MOVES DECK ROLL

LEVER CONTROL AND FUNCTIONS

#5 -- safety shield

OPERATION

OPERATION LEVER #1 MOVES MAIN BOOM LEVER #2 MOVES SECONDARY BOOM

LEVER #3 MOVES DECK ROLL LEVER #4 MOVES BOOM SWIVEL LEVER #5

OPERATES SAFETY SHIELD

Cheetah Operation Section

OPERATION UNSTOWING BOOM

MOWER OPERATION

OPERATION

CONTINUED

TRANSPORTING MOWER

Transporting under the units own power

OPERATION

OPERATION

Transporting unit by flatbed trailer

INSPECTION SHEETS

OPERATION

BOOM MOWER PRE-OPERATION Inspection

Mower ID# Make Date Shift

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

OPERATION

TRACTOR PRE-OPERATION Inspection

Tractor ID# Make Date Shift

OPERATION

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

FRONT END LOADER PRE-OPERATION Inspection

DO NOT OPERATE an UNSAFE TRACTOR or FRONT END LOADER

OPERATION

Mower ID# Make Date Shift

OPERATION

TRACTOR PRE-OPERATION Inspection

Tractor ID# Make Date Shift

DO NOT OPERATE an UNSAFE TRACTOR or FRONT END LOADER

MAINTENANCE SECTION

Cheetah Maintenance Section

MAINTENANCE

MAINTENANCE PRECAUTIONS

BREAK IN PERIOD

MAINTENANCE REGULAR MAINTENANCE

DAILY OR EVERY 8 HOURS

SERVICE

COMMENTS

MAINTENANCE WEEKLY OR EVERY 50 HOURS

TROUBLE SHOOTING

MONTHLY OR EVERY 150 HOURS

YEARLY OR EVERY 500 HOURS

MAINTENANCE

SYMPTOMS

CAUSE

REMEDY

MAINTENANCE TORQUE SPECIFICATIONS

MAINTENANCE LUBRICATION RECOMMENDATIONS

General Specification

Description

Application

MAINTENANCE POLYCARBONATE CARE & MAINTENANCE

CLEANING THE SUPERCOAT HARD-COAT

GRAFFITI REMOVAL

DETAILED MAINTENANCE

RECOMMENDED FILLING INSTRUCTIONS FOR HYDRAULIC RESERVIORS

MAINTENANCE

REPLACING IN-TANK HYDRAULIC FILTER

MAINTENANCE DETAILED MAINTENANCE

REPLACEING HIGH PRESSURE HYDRAULIC FILTER ELEMENT

HEAD BOWL

MAINTENANCE GREASING PIVOT POINTS - BOOM AND SWIVEL

GREASING SPINDLE

MAINTENANCE TIGHTENING KNIFE BOLTS AND DISK BOLTS

TIGHTENING SPINDLE BOLTS

MAINTENANCE GREASING THE BOOM SWIVEL

GREASING PUMP DRIVE SHAFT COUPLER

MAINTENANCE BALL VALVES

MAINTENANCE GREASING BOOM CYLINDER PIVOT POINTS

BOOM FLAIL KNIFE REPLACEMENT

Knives should not be welded on for any reason

THE SPINDLE ASSEMBLY

MAINTENANCE CHEETAH SPINDLE ASSEMBLY

INSTALLATION AND BEARING ADJUSTMENT

MAINTENANCE BEARING INSTALLATION

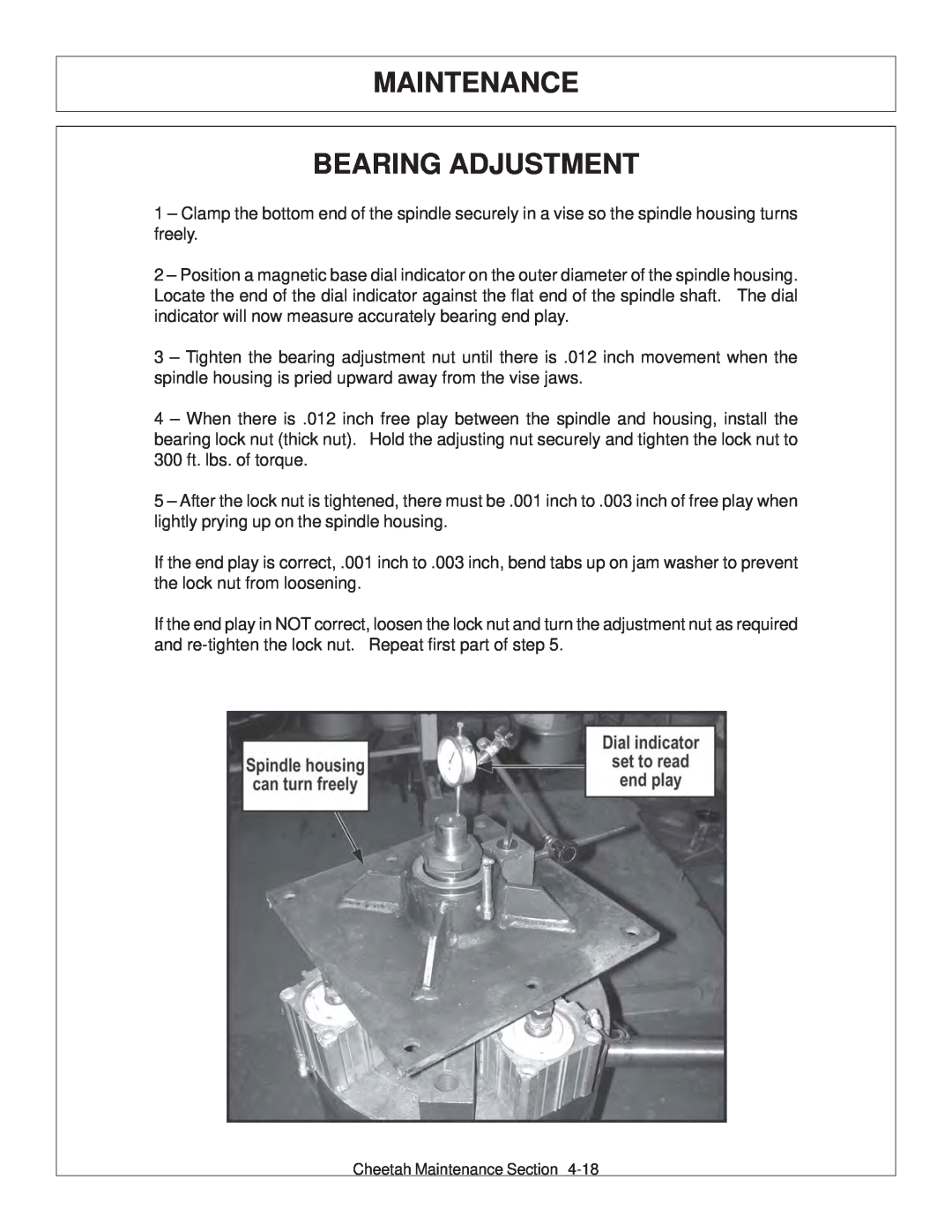

MAINTENANCE BEARING ADJUSTMENT

MAINTENANCE

DAILY MAINTENANCE SCHEDULE

The following services should be performed daily or every 8 hours

MAINTENANCE

Cheetah Maintenance Section

PARTS SECTION

JD 5101E - CHEETAH BOOM MOWER

PARTS ORDERING GUIDE

Tiger Corporation

3301 N. Louise Ave Sioux Falls, SD

Direct any questions regarding parts to

PARTS SECTION TABLE OF CONTENTS

ASSEMBLY

SECTION

TRACTOR SPECIFIC PARTS

TRACTOR MOUNT KIT - MAIN FRAME 5101E

Parts Section

TRACTOR MOUNT KIT - MAIN FRAME 5101E

FLTR ASSY,IN-TANK CPLT,SAE10MP

TRACTOR MOUNT KIT - HYDRAULICS 5101E

Parts Section

TRACTOR MOUNT KIT - HYDRAULICS 5101E

06300033

TRACTOR MOUNT KIT - MAIN FRAME 5101E - LOADER

Parts Section

TRACTOR MOUNT KIT - MAIN FRAME 5101E - LOADER

06700091

AVAIL

TANK,RES,ASSY,WHEEL WELL

TRACTOR MOUNT KIT - HYDRAULICS 5101E - LOADER

Parts Section

TRACTOR MOUNT KIT - HYDRAULICS 5101E - LOADER

REFER TO MAIN FRAME PARTS

REFER TO MAIN FRAME PARTS

REFER TO MAIN FRAME PARTS

TRACTOR MOUNT KIT - WHEEL WELL TANK

Parts Section

TRACTOR MOUNT KIT - WHEEL WELL TANK

06700091

AVAIL

TANK,RES,ASSY,WHEEL WELL

TRACTOR MOUNT KIT - HYDRO, WHEEL WELL TANK

Parts Section

TRACTOR MOUNT KIT - HYDRO, WHEEL WELL TANK

BRAKE VALVE - REFER TO MAIN FRAME PARTS

AXLE BRACE,RH - REFER TO MAIN FRAME PARTS

AXLE BRACE,LH - REFER TO MAIN FRAME PARTS

BOOM MOUNT KIT - BOOM SWIVEL / BOOM REST

Parts Section

BOOM MOUNT KIT - BOOM SWIVEL / BOOM REST

DESCRIPTION

SWITCH BOX AND JOYSTICK 5101E

Parts Section

SWITCH BOX AND JOYSTICK 5101E

DESCRIPTION

LIFT VALVE - JOYSTICK CONTROL

Parts Section

LIFT VALVE - JOYSTICK CONTROL

VALVE,PRIORITY,DF OLS80,10 BAR

CABLE CONTROLS - SCV ONLY

DESCRIPTION

CABLE CONTROLS - WITH MID-MOUNT VALVE

DESCRIPTION

LIFT VALVE - CABLE CONTROL, CAB

Parts Section

LIFT VALVE - CABLE CONTROL, CAB

DESCRIPTION

POLYCARBONATE SAFETY WINDOW - 5101E, CAB

DESCRIPTION

SOLENOID VALVE SWITCH AND WIRING

TEMPERATURE SENSOR

WHEEL SPACER

RING,SPACER,WHEEL,JD

WHEEL WEIGHT ASSEMBLY

DESCRIPTION

Parts Section

COMMON PARTS SECTION

CHEETAH BOOM MOWER

PARTS ORDERING GUIDE

Tiger Corporation

3301 N. Louise Ave Sioux Falls, SD

Cheetah Common Section

PARTS SECTION TABLE OF CONTENTS

SECTION

TRACTOR SPECIFIC PARTS

CHEETAH QUICK COUPLERS

CHEETAH QUICK COUPLERS - MAIN BOOM

Cheetah Common Section

CHEETAH QUICK COUPLERS - MAIN BOOM

DESCRIPTION

5 *REF. PREFORMED TUBES - REFER TO BOOM ARM PARTS

6 *REF. #16 HOSE - REFER TO HYDRAULIC PARTS

CHEETAH BOOM ARM ASSEMBLY

Cheetah Common Section

CHEETAH BOOM ARM ASSEMBLY

DESCRIPTION

CHEETAH ROTARY MOWER DECK

Cheetah Common Section

CHEETAH ROTARY MOWER DECK

CHEETAH ROTARY PIVOT ASY

Cheetah Common Section

CHEETAH ROTARY PIVOT ASY

DESCRIPTION

DAN FOSS VALVE

Cheetah Common Section

DAN FOSS VALVE

06502095

VLV,5SP,32PVG

06502074

5SP HUSCO - POWER BEYOND

Cheetah Common Section

5SP HUSCO - POWER BEYOND

DESCRIPTION

VALVE SECTION DOUBLE ACTING, SPRING METERED

5SP HUSCO - OPEN CENTER

Cheetah Common Section

5SP HUSCO - OPEN CENTER

PART NO. QTY

DESCRIPTION

4SP HUSCO LIFT VALVE - FLAIL - OPEN CENTER

Cheetah Common Section

4SP HUSCO LIFT VALVE - OPEN CENTER

PART NO. QTY

DESCRIPTION

CHEETAH ROTARY MOTOR

Cheetah Common Section

MOTOR ASSEMBLY - CHEETAH ROTARY

CHEETAH ROTARY MOTOR

ROTARY SPINDLE ASSEMBLY

Cheetah Common Section

ROTARY SPINDLE ASSEMBLY

DESCRIPTION

CHEETAH FLAIL HEAD ASSY

Cheetah Common Section

CHEETAH FLAIL HEAD ASSY

CUTTERSHAFT,ASSY,GRASS,CHEETAH, OPTIONAL

CHEETAH FLAIL - CUTTER SHAFT ASSY

Cheetah Common Section

CHEETAH FLAIL - CUTTER SHAFT ASSY

HOSE, SLEEVE, CHEETAH, FLAIL, SM NOT SHOWN

CHEETAH FLAIL MOTOR

Cheetah Common Section

CHEETAH FLAIL MOTOR

SEAL KIT INCLUDES 14, 15, 16, 17, AND

CHEETAH CYLINDER BREAKDOWNS

Cheetah Common Section

CHEETAH CYLINDER BREAKDOWNS

CHEETAH CYLINDER BREAKDOWNS

Cheetah Common Section

CHEETAH CYLINDER BREAKDOWNS

RESERVOIR TANK FILTER ASSEMBLY

BRAKE VALVE ASSEMBLY W/ METRI PAK

DESCRIPTION

BOOM TRAVEL LOCK

MAIN BOOM CYLINDER - REFER OT BOOM ASY

SOLENOID BRAKE VALVE HYDRAULIC SCHEMATIC

BRAKE VALVE TROUBLESHOOTING

FAILURE MODE

CHECK STEPS

JOYSTICK SWITCHBOX SERVICE PARTS

Cheetah Common Section

JOYSTICK SWITCHBOX SCHEMATIC

Cheetah Common Section

HUSCO CONTROLS SWITCHBOX

Cheetah Common Section

PAGE INTENSIONALLY LEFT BLANK

Cheetah Common Section

OPTIONAL PUMP GUARD KIT

DESCRIPTION

OPTIONAL PUMP AND GRILL GUARD KIT

DESCRIPTION

TROUBLESHOOTING

JOYSTICK TROUBLESHOOTING

Possible electronic problems

Boom operation not responding to joystick movement

TROUBLESHOOTING

Possible hydraulic problems

Hydraulic inspection

HYDRAULIC - TROUBLESHOOTING GUIDE

Cheetah Common Section

ELECTRICAL - TROUBLESHOOTING GUIDE

Cheetah Common Section

Cheetah Common Section

WARRANTY SECTION

Warranty Section

Page

WARRANTY INFORMATION

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THOSE EXPRESSED HEREIN

ONE LAST WORD

SAFETY IS YOU

TO THE OWNER / OPERATOR / DEALER

OWNER REQUIREMENTS

OPERATOR REQUIREMENTS

Printed in USA Tiger Corporation