Auger Gearbox Service

INSTALLATION

Installation of the auger assembly into the auger housing can be done whether the auger housing and traction assemblies are connected or not. There is no significant time savings to either sequence.

1.All

1

|

|

|

Figure 19 | ||

1. Bearing and flange

2.Make sure all the parts are installed on the auger assembly. All spacers, thrust washers, and auger bearings need to be hanging on the shafts.

(Including the scraper for models 38065 and 38080.)

3.Slide the assembly into the housing, directing the input shaft into the rear bearing.

4.Start the cap screws from the side plates into the bearings that support the auger output shafts. Some models have 2 cap screws into a fixed bearing; others have 4 cap screws into a self- aligning bearing.

5.Models using four bolt bearings ONLY - Strike the side plate and bearing area with a rubber mallet three or four times, then secure the bearings. The jolt aligns the bearings (Figure 20).

|

|

|

Figure 20 |

|

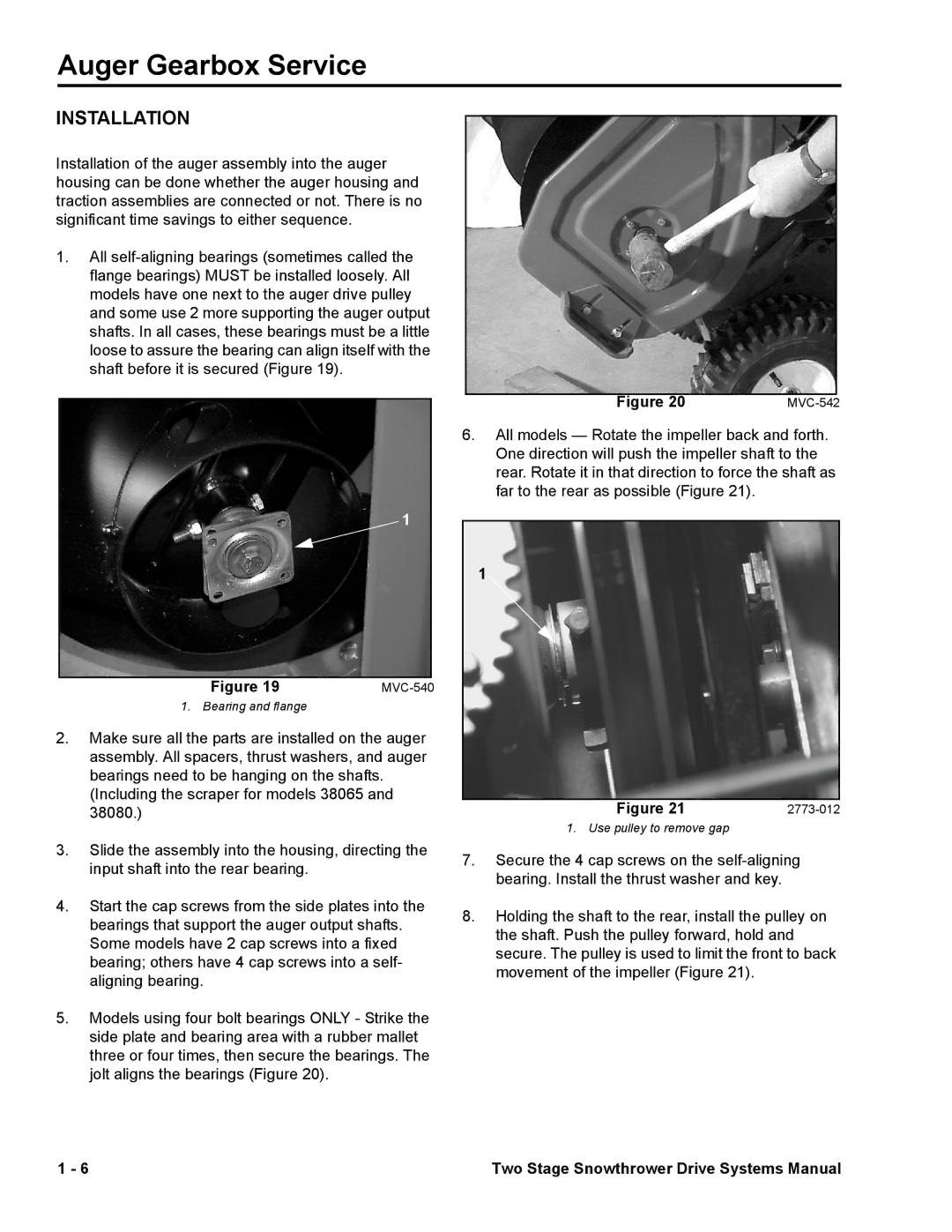

6.All models — Rotate the impeller back and forth. One direction will push the impeller shaft to the rear. Rotate it in that direction to force the shaft as far to the rear as possible (Figure 21).

1

Figure 21 |

1. Use pulley to remove gap

7.Secure the 4 cap screws on the

8.Holding the shaft to the rear, install the pulley on the shaft. Push the pulley forward, hold and secure. The pulley is used to limit the front to back movement of the impeller (Figure 21).

1 - 6 | Two Stage Snowthrower Drive Systems Manual |