Traction Drive Systems

TROUBLESHOOTING THE TRACTION DRIVE — ALL MODELS

Drive slipping:

1.Verify adjustment of traction drive linkage.

2.Make sure the engagement spring and idler spring are in place and undamaged.

3.Verify that the drive plate and friction wheel are clean and free of grease or oil. Clean with alcohol or something that does not leave a residue.

4.Replace the friction wheel if worn.

DISASSEMBLY — TORO MODELS 38065, 38080, 38085

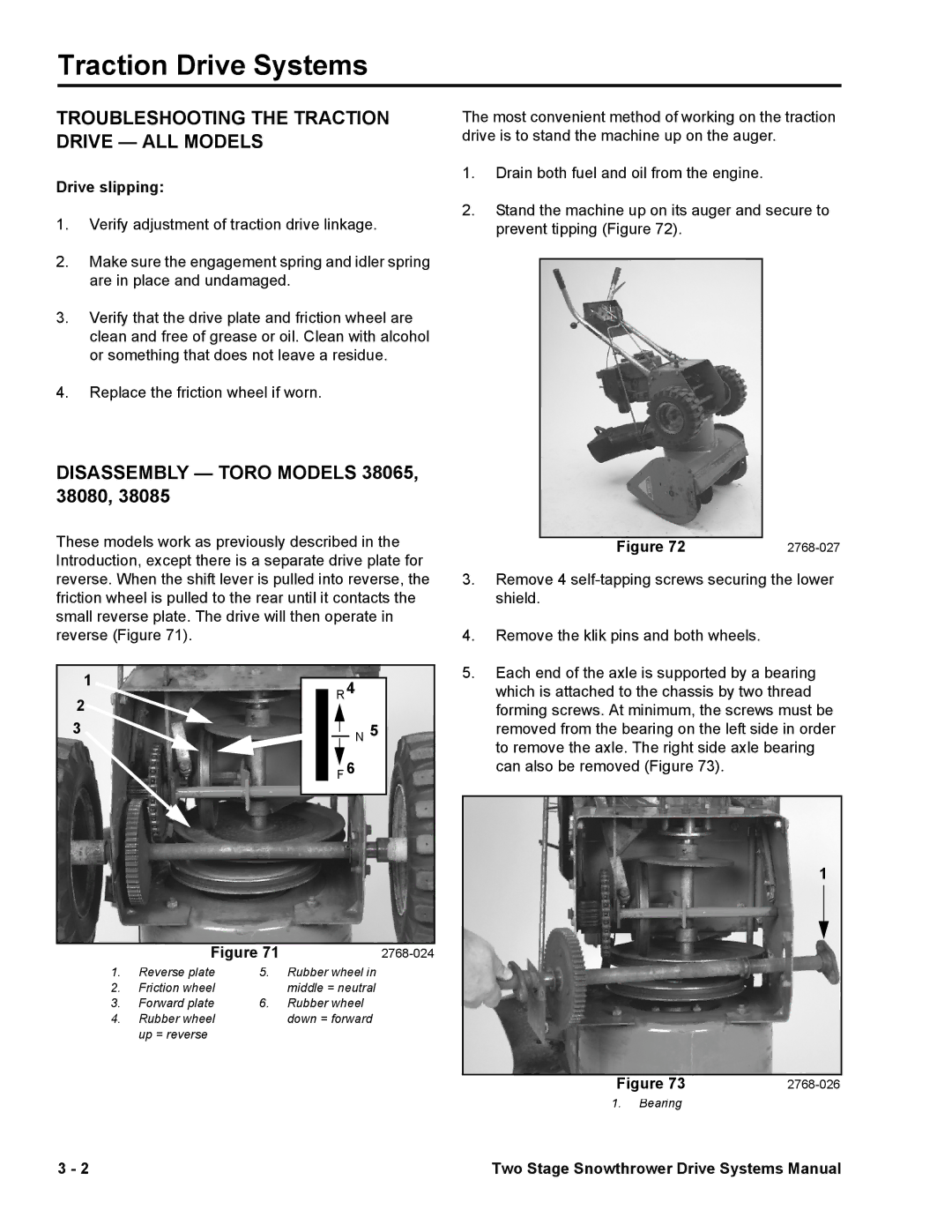

These models work as previously described in the Introduction, except there is a separate drive plate for reverse. When the shift lever is pulled into reverse, the friction wheel is pulled to the rear until it contacts the small reverse plate. The drive will then operate in reverse (Figure 71).

1 |

|

| R 4 |

2 |

|

| |

|

|

| |

3 |

|

| N 5 |

|

|

| F 6 |

| Figure 71 | ||

1. | Reverse plate | 5. | Rubber wheel in |

2. | Friction wheel |

| middle = neutral |

3. | Forward plate | 6. | Rubber wheel |

4. | Rubber wheel |

| down = forward |

| up = reverse |

|

|

The most convenient method of working on the traction drive is to stand the machine up on the auger.

1.Drain both fuel and oil from the engine.

2.Stand the machine up on its auger and secure to prevent tipping (Figure 72).

|

|

Figure 72 |

3.Remove 4

4.Remove the klik pins and both wheels.

5.Each end of the axle is supported by a bearing which is attached to the chassis by two thread forming screws. At minimum, the screws must be removed from the bearing on the left side in order to remove the axle. The right side axle bearing can also be removed (Figure 73).

1

Figure 73 |

1. Bearing

3 - 2 | Two Stage Snowthrower Drive Systems Manual |