Commercial Self-Contained

December

Introduction

Signature Series Self-Contained Units

Contents

Features and Benefits

Standard Features

Optional Features

Integrated Self-Contained Systems

Integrated Comfort System ICS

Low Torque Variation

Proven DesignThroughTesting and Research

Trane 3-DScroll Compressor

Supply Air Ductwork

Application Considerations Self-Contained

Return Air Ductwork

Equipment Room Location and Orientation

Isolation Recommendations

Condenser Water Piping

Unit Operating Limits

Considerations

Application

Air Cooled

Condenser

Unit Capacities

Procedure Self-Contained

Selection

Waterside Economizer Capacity

Selection Example Design Conditions

Unit Selection

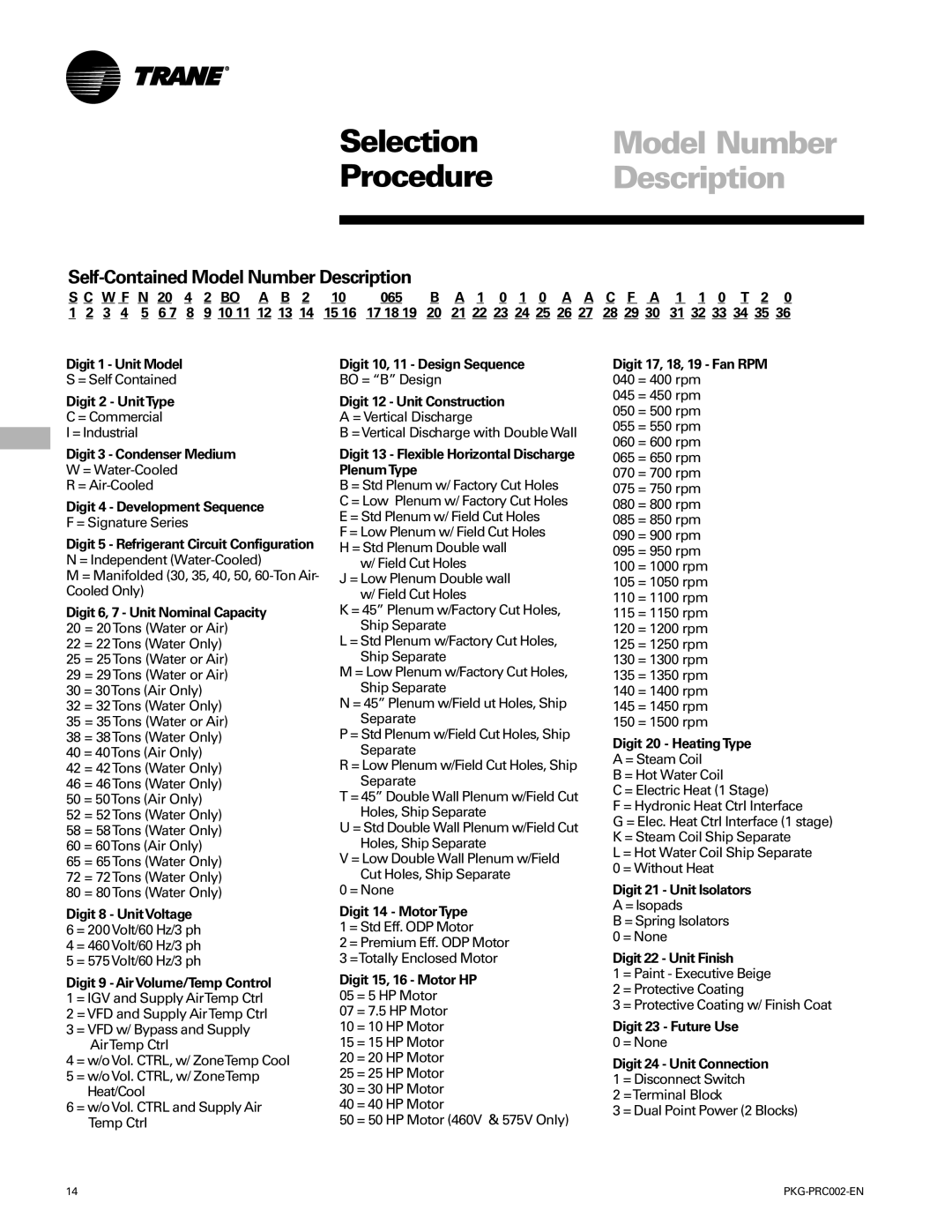

Description

Procedure

Model Number

Self-Contained Model Number Description

Self-Contained Accessory Model Number Description

Remote Air-Cooled Condenser Model Number Description

General Data

Tons

Table GD-3. SCWF/SIWF Water-Cooled Self-Contained, 42-80Tons

SCRF/SIRF

Table GD-4. SCRF/SIRF Air-Cooled Self-Contained

General Data

CCRC/CIRC

Heating Coil

Table GD-7. Self-Contained Heating Coil

Drops

Data

Chart PD-5. Airside Pressure Drop

Performance

Drops

Airside Pressure

Heating Coils

Discharge Plenum

20 to 38 Ton Unit 42 to 80 Ton Unit

Airside Pressure

Airside Economizer with Standard Damper

Airside Economizer with Traq Damper

Pressure Drop

Chart PD-21. Waterside Pressure Drop SCWF/SIWF 35

Waterside

SCWF/SIWF

Performance Water-Cooled Data

Table PD-1. CFM Capacity Correction Table

Table PD-2. SCWF/SIWF 20 Economizer Full Capacity 8,000 cfm

Water-Cooled

20 Ton

Table PD-3. SCWF/SIWF 20 Economizer Low Capacity 8,000 cfm

Entering WaterTemp Entering Air 75 F 85 F 95 F

Table PD-6. SCWF/SIWF 22 Economizer Low Capacity 8,800 cfm

22 Ton

Table PD-5. SCWF/SIWF 22 Economizer Full Capacity 8,800 cfm

EnteringWaterTemp Entering Air 75 F 85 F 95 F

25 Ton

Table PD-9. SCWF/SIWF 25 Economizer Low Capacity 10,000 cfm

Entering Water Temp Entering Air 75 F 85 F 95 F

29 Ton

Table PD-12. SCWF/SIWF 29 Economizer Low Capacity 11,600 cfm

84.2

32 Ton

Table PD-15. SCWF/SIWF 32 Economizer Low Capacity 12,800 cfm

94.5

35 Ton

Table PD-18. SCWF/SIWF 35 Economizer Low Capacity 14,000 cfm

401 320

38 Ton

Table PD-21. SCWF/SIWF 38 Economizer Low Capacity 15,200 cfm

434 373

42 Ton

Table PD-24. SCWF/SIWF 42 Economizer Low Capacity 16,800 cfm

403 84.1

46 Ton

Table PD-27. SCWF/SIWF 46 Economizer Low Capacity 18,400 cfm

83.8

52 Ton

Table PD-30. SCWF/SIWF 52 Economizer Low Capacity 20,800 cfm

596 471

58 Ton

Table PD-33. Scwfsiwf 58 Economizer Low Capacity 23,200 cfm

663 571

65 Ton

Table PD-36. SCWF/SIWF 65 Economizer Low Capacity 26,000 cfm

Entering Water Temp Entering Air

72 Ton

Table PD-39. SCWF/SIWF 72 Economizer Low Capacity 28,000 cfm

83.7

80 Ton

Table PD-42. SCWF/SIWF 80 Economizer Low Capacity 29,800 cfm

891 761

Air-Cooled

Table PD-45. SCRF/SIRF 25 Gross Cooling Capacity 11,600 cfm

Table PD-46. SCRF/SIRF 29 Gross Cooling Capacity 12,800 cfm

30 Ton

Table PD-47. SCRF/SIRF 30 Gross Cooling Capacity 14,000 cfm

Table PD-48. SCRF/SIRF 35 Gross Cooling Capacity 15,200 cfm

40 Ton

Table PD-49. SCRF/SIRF 40 Gross Cooling Capacity 18,400 cfm

50 Ton

Table PD-50. SCRF/SIRF 50 Gross Cooling Capacity 23,200 cfm

Table PD-51. SCRF/SIRF 60 Gross Cooling Capacity 29,800 cfm

Performance Air-Cooled

Data60-Ton

Table PD-52. HotWater Heating Capacity

Self-Contained

Heating Coils

Table PD-53. Steam Heating Capacity

Controls

Available Input and Output Points

Human Interface Panel HI

Standard IntelliPak Unit Control Features

IntelliPak Unit Features

Main menus of the human interface panels are

Control Sequences Operation

Sequence

Controls Operation

Gbas Binary Outputs

Generic Building Automation System Module Gbas Option

Gbas Analog Inputs

Demand Limiting Binary Input

Water Purge

Airside Options

Air-Cooled Condensers

Inlet GuideVane Control

Heating Electric

Occupied ZoneTemperature Control

Unoccupied ZoneTemperature Control Cooling and Heating

Heating Hot Water or Steam

Supply Air Tempering Hot Water and Steam Units Only

Supply Air Temperature Control Unit Sequence Operation

Supply Air Setpoint Reset

Standard On All Units

Zone Sensor

Controls Options

Model Number Digit 6 = A, BAYSENS017

Thermometer to indicate temperature in the zone

Setpoint thumbwheel for local setpoint adjustment

Selection Procedures

Electrical Data

Table ED-7. CCRC/CIRC Condenser Electrical Data

Electrical Data SCWF/SCRF

Table ED-6. Single Stage Electric Heat Electrical Data

Dimensions Self-Contained Weights Tons

Ton Self-Contained

Dimensions Self-Contained Weights 40-80 Ton

Discharge Dimensions Metric mm

Detail B Discharge Dimensions

Discharge Dimensions English inches

Detail a Electrical Connections

Dimensions Air-Cooled Weights Condenser

Ccrc Unit Dimensions

Refrigerant and Electrical Connections

Dimensions

Weights

Front View Looking at Control Panel

Hot Water Coil

Steam Coil

Plenum Dimensions Metric mm

Dimensions

Plenum Dimensions English inches

Flexible Horizontal Discharge Plenum

Airside Economizer

Airside

Economizer

Airside Economizer Dimensions English inches

Airside Economizer Dimensions Metric mm

Zone Sensors

Field-Installed

Adjustment

Dual Setpoint, Manual/Automatic

Programmable Night-Setback Sensor

Zone Temperature Sensor Only

Function Lights

Clearances

Service

Service/Code Clearance Requirements

Self-Contained Models

Top View CCRC/CIRC 50

Top View CCRC/CIRC 20

Top View CCRC/CIRC 35

Table W-2. Unit Weights CCRC/CIRC

Dimensions Weights

Table W-1. Unit Weights SCWF/SCRF/SIWF/SIRF

Table W-3. Variable Frequency Drive Weights

Mechanical Specifications Self-Contained

Signature Series Self Contained Units

Mechanical Air-CooledSpecifications Condenser

Supply Air Temperature Control with Inlet GuideVanes

Mechanical Specifications Options

Air Volume/Temperature Control Zone Temperature Control

Self-Contained Options

Airside Economizer Interface

Comparative Enthalpy Control

Standard Two-Position Damper Interface

Airside Economizer Interface with Comparative Enthalpy

Low Entering Air Temperature Protection Device

Water Flow Switch

Service Valves

Non-fused Disconnect Switch

Cupro-Nickel Condenser

Protective Coating Cabinet

Coils

Stainless Steel Drain Pan

Literature Order Number