Maintenance

Preventive Maintenance

Maintenance on the unit is simplified with the following preventive sugges- tions:

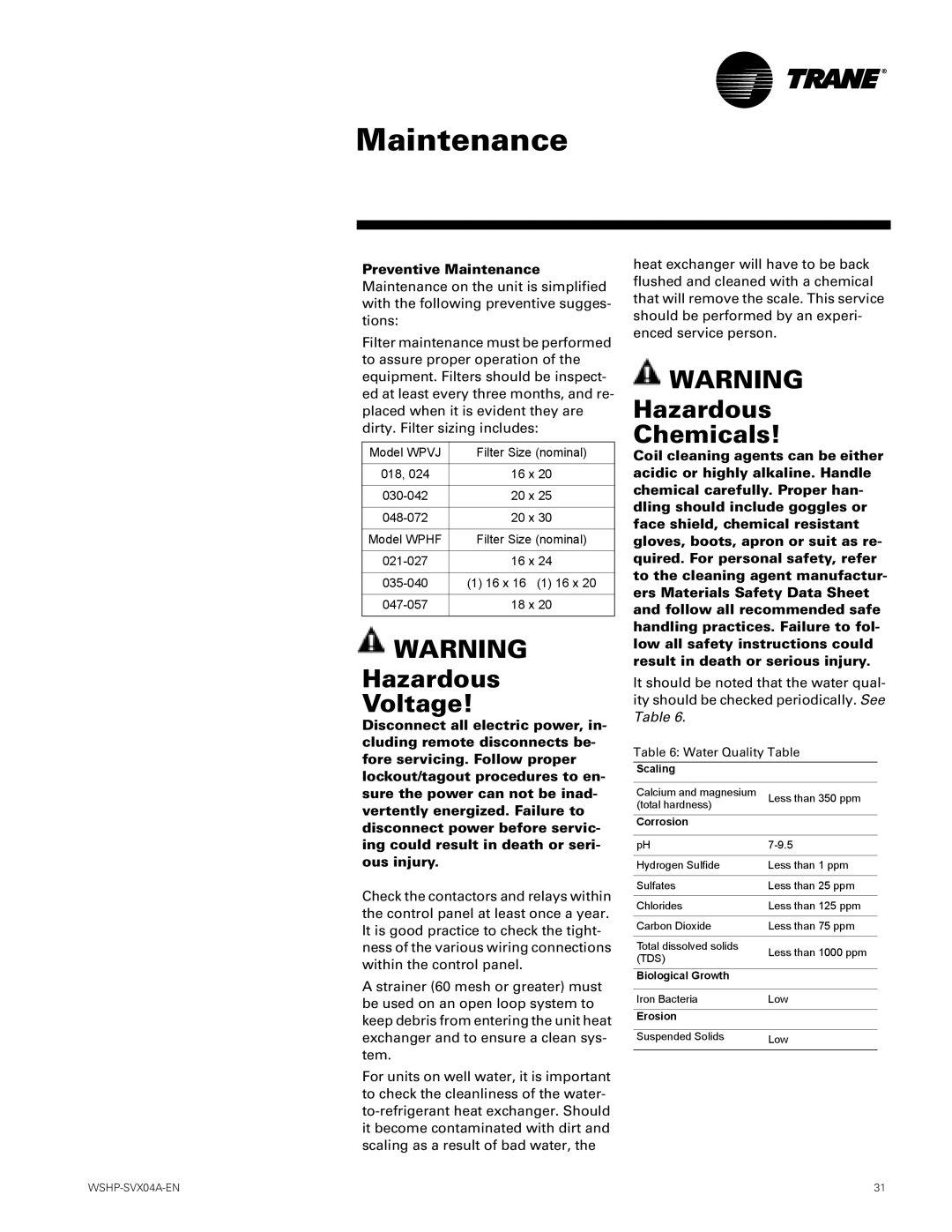

Filter maintenance must be performed to assure proper operation of the equipment. Filters should be inspect- ed at least every three months, and re- placed when it is evident they are dirty. Filter sizing includes:

Model WPVJ | Filter Size (nominal) |

|

|

018, 024 | 16 x 20 |

|

|

20 x 25 | |

|

|

20 x 30 | |

|

|

Model WPHF | Filter Size (nominal) |

|

|

16 x 24 | |

|

|

(1) 16 x 16 (1) 16 x 20 | |

|

|

18 x 20 | |

|

|

![]() WARNING

WARNING

Hazardous

Voltage!

Disconnect all electric power, in- cluding remote disconnects be- fore servicing. Follow proper lockout/tagout procedures to en- sure the power can not be inad- vertently energized. Failure to disconnect power before servic- ing could result in death or seri- ous injury.

Check the contactors and relays within the control panel at least once a year. It is good practice to check the tight- ness of the various wiring connections within the control panel.

A strainer (60 mesh or greater) must be used on an open loop system to keep debris from entering the unit heat exchanger and to ensure a clean sys- tem.

For units on well water, it is important to check the cleanliness of the water-

heat exchanger will have to be back flushed and cleaned with a chemical that will remove the scale. This service should be performed by an experi- enced service person.

![]() WARNING

WARNING

Hazardous

Chemicals!

Coil cleaning agents can be either acidic or highly alkaline. Handle chemical carefully. Proper han- dling should include goggles or face shield, chemical resistant gloves, boots, apron or suit as re- quired. For personal safety, refer to the cleaning agent manufactur- ers Materials Safety Data Sheet and follow all recommended safe handling practices. Failure to fol- low all safety instructions could result in death or serious injury.

It should be noted that the water qual- ity should be checked periodically. See Table 6.

Table 6: Water Quality Table

Scaling

Calcium and magnesium | Less than 350 ppm | |

(total hardness) | ||

| ||

Corrosion |

| |

|

| |

pH | ||

|

| |

Hydrogen Sulfide | Less than 1 ppm | |

|

| |

Sulfates | Less than 25 ppm | |

|

| |

Chlorides | Less than 125 ppm | |

|

| |

Carbon Dioxide | Less than 75 ppm | |

|

| |

Total dissolved solids | Less than 1000 ppm | |

(TDS) | ||

| ||

Biological Growth |

| |

|

| |

Iron Bacteria | Low | |

|

| |

Erosion |

| |

|

| |

Suspended Solids | Low | |

|

|

31 |