Ignoring a leak can result in severe transmission damage.

If a cover leaks, try tightening any loose screws or bolts. If the fasteners are tight, a new gasket or oil seal may be required. If the leak is from around a shaft and oil seal, the oil seal probably needs to be replaced. See an authorized service dealer.

Changing Oil

Oil level should be visually checked if evidence of a leak is present. Oil should be added in such cases, but changing the transmission oil as part of general maintenance is unnecessary

Checking Oil Level

Check the oil level after every 30 hours of operation and whenever there is any oil leakage.

IMPORTANT:Never operate the tiller if the transmission is low on oil.

1.Position the tiller on a level surface.

2.Remove the fill plug found on the front of the transmission. See Figure 2.

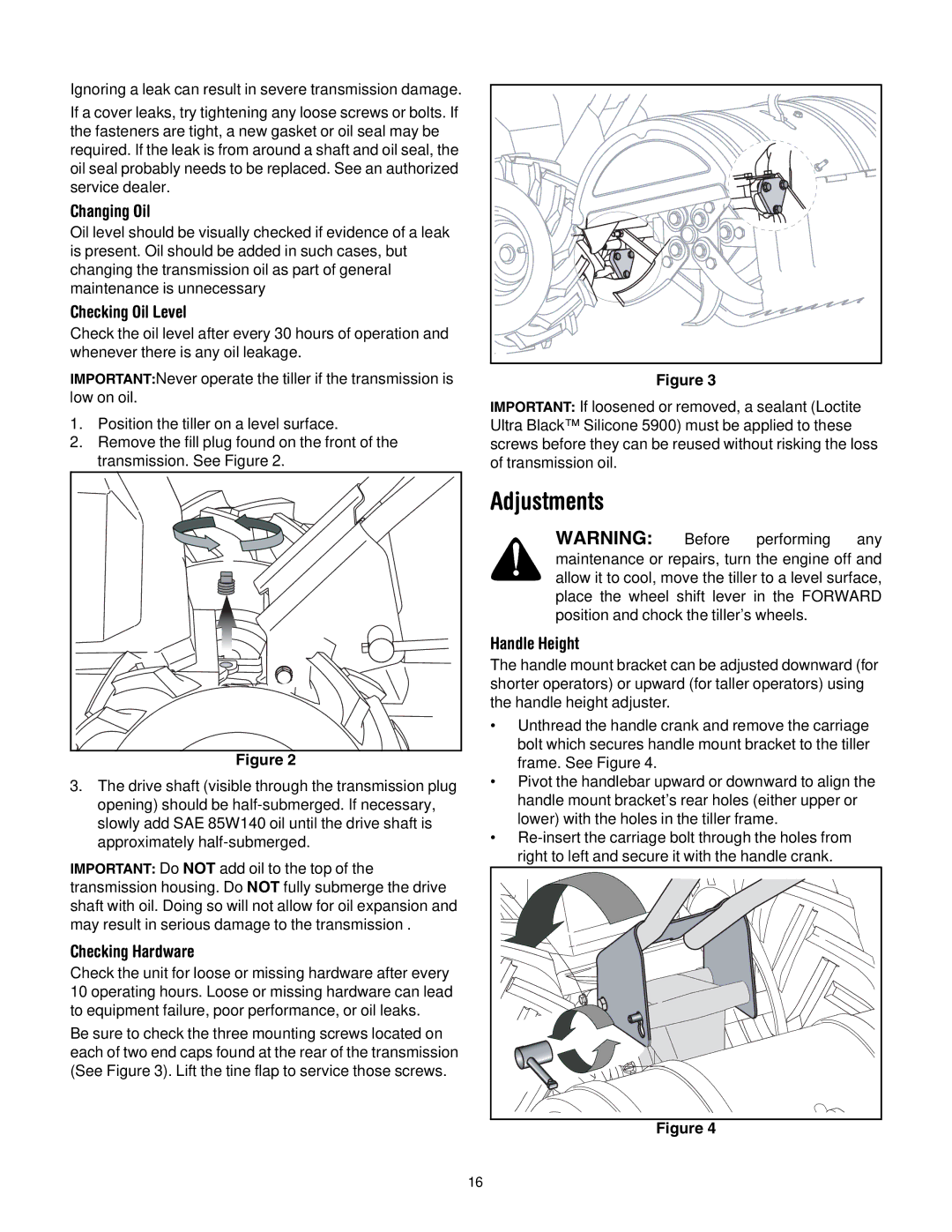

Figure 3

IMPORTANT: If loosened or removed, a sealant (Loctite Ultra Black™ Silicone 5900) must be applied to these screws before they can be reused without risking the loss of transmission oil.

Figure 2

3.The drive shaft (visible through the transmission plug opening) should be

IMPORTANT: Do NOT add oil to the top of the transmission housing. Do NOT fully submerge the drive shaft with oil. Doing so will not allow for oil expansion and may result in serious damage to the transmission .

Checking Hardware

Check the unit for loose or missing hardware after every 10 operating hours. Loose or missing hardware can lead to equipment failure, poor performance, or oil leaks.

Be sure to check the three mounting screws located on each of two end caps found at the rear of the transmission (See Figure 3). Lift the tine flap to service those screws.

Adjustments

WARNING: Before performing any maintenance or repairs, turn the engine off and allow it to cool, move the tiller to a level surface, place the wheel shift lever in the FORWARD position and chock the tiller’s wheels.

Handle Height

The handle mount bracket can be adjusted downward (for shorter operators) or upward (for taller operators) using the handle height adjuster.

•Unthread the handle crank and remove the carriage bolt which secures handle mount bracket to the tiller frame. See Figure 4.

•Pivot the handlebar upward or downward to align the handle mount bracket’s rear holes (either upper or lower) with the holes in the tiller frame.

•

Figure 4

16