TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH

IMPORTANTREAD SAFETY RULES AND INSTRUCTIONS CAREFULLY

PRINTED IN USA

FORM NO. 770-10598A

Content

TABLE OF CONTENTS

FINDING MODEL NUMBER

ENGINE INFORMATION

Safety Alert Symbol

1 Safety

Section

Training

c. Use slower wheel, tine and engine speeds

Section 1 Safety

Antidotes

Operating Symbols

Maintenance and Storage

Decals

TO AVOID SERIOUS INJURY

Tools/Materials Needed for Assembly

2 Assembly

Loose Parts List Qty. Description

Introduction

Adjustment

Section 2 Assembly

Wire

STEP 4 Connect Forward Interlock Wire Harness

STEP 6 Check Gear Oil Levels

STEP 8 Attach Engine Throttle Lever and Cable

STEP 9 Adjust Air Pressure in Tires

STEP 7 Add Motor Oil to Engine

Oil Level Hole

Battery produces explosive gases

STEP 2 Install the Battery Cables

STEP 1 Connect the Wire Harness Receptacle

ASSEMBLING THE ELECTRIC START SYSTEM

PTO Attachments Feature

3 Features and Controls

G F A B E C D

Wheels/Tines/PTO Drive Lever

Handlebar Height Adjustment Lever

Section 3 Features and Controls

Wheel Speed Lever

Tines/PTO Clutch Lever

Keyswitch Starter

Section 3 Features and Controls

Engine Controls

Engine Throttle Lever

4 Operation

Pre-Start Checklist

INTRODUCTION

Break-In Operation

Starting the Engine

Section 4 Operation

To help prevent serious personal injury or damage to equipment

Avoid engine muffler and nearby

Operating the Tiller

Cold Weather Operation

Stopping the Engine and Tiller

Moving the Tiller Forward and Tilling

Stopping Reverse Motion

Moving the Tiller in Reverse

To Stop the Engine

Making Turns

How to Check the Interlock System

Testing the Forward Interlock Safety System

Loading and Unloading the Tiller

Transporting The Tiller Around Your Property

Loading the Tiller

Changing Speed Belts

Unloading the Tiller

Changing Belt From LOW Range to HIGH Range

Changing Belt From HIGH Range to LOW Range

Choosing Wheel and Tine Speeds

Tilling Tips & Techniques

Use shallow depth regulator settings. Till gradually deeper

TABLE 2-4 WHEEL SPEED AND BELT RANGE SELECTION GUIDE

Let the tiller do the work

Avoid making footprints

Do not use FAST wheel speed position when on sloped ground

Suggested tilling patterns

Tilling on slopes

B. Terrace Gardening

Clearing the tines

Wide-Row Planting

POWER COMPOSTING

Tilling Under Corn

Soil Enrichment Idea

VERY IMPORTANT

PTO POWER UNIT

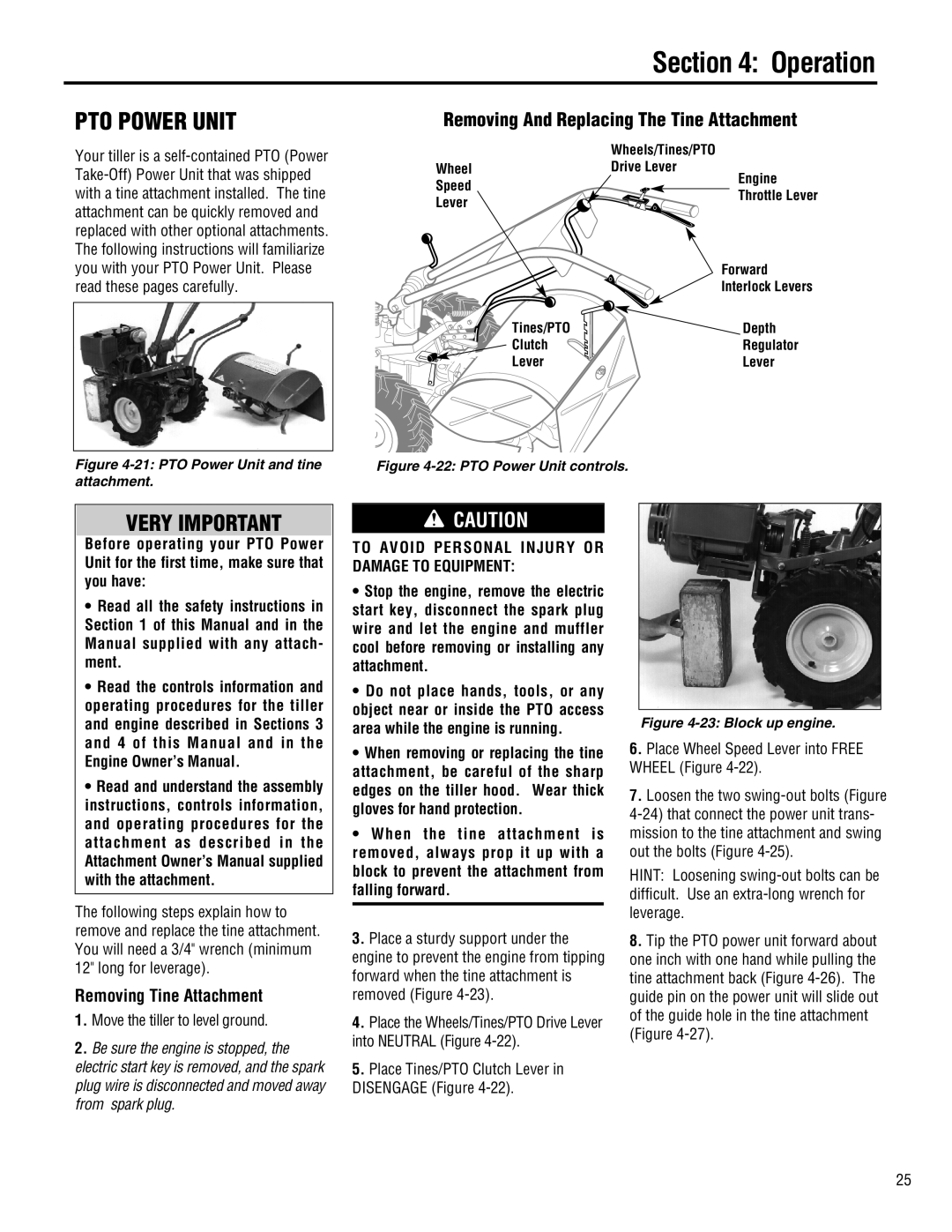

Removing And Replacing The Tine Attachment

Removing Tine Attachment

Installing the Tine Attachment

PTO POWER UNIT OPERATING INSTRUCTIONS

Setting Up Stationary Attachments

Guide Pin Mounting Hole

Starting The Engine

Setting Up Non-Powered Attach- ments

Operating Stationary Attachments

Stopping the Engine

REQUIRED MAINTENANCE SCHEDULE

5 Maintenance

PROCEDURE

Every

Tighten Bolts and Nuts

Section 5 Maintenance

Tiller Lubrication

Checking the Power Unit Oil Level

Transmission Gear Oil Maintenance

Checking for Oil Leaks

Checking Gear Oil Levels

Checking the Tine Attachment Oil Level

Adding or Changing Gear Oil

For Dipsticks With Hot/Cold Markings

Draining and Filling the PTO Power Unit Transmission

Adding Gear Oil to the PTO Power Unit Transmission

Adding Gear Oil to the Tine Attachment Transmission

Draining and Filling the Tine Attachment Transmission

Measuring and Adjusting Drive Belt Tension

Drive Belt Maintenance

How to Measure Belt Tension

5/16 1/4 Belt Adjustment Tool

Removing the Belt

Replacing the Drive Belt

Replacing the Drive Belt

Push Belt UP

Reverse Disc Inspection

Reverse Drive System Maintenance

Installing a New Reverse Disc

Checking and Adjusting Reverse the Drive System

Checking and Adjusting Reverse Disc

Replacing the Reverse Disc

Adjusting Reverse Drive

Bolo Tine Maintenance

Adjustment Bolt Jam Nut

Checking Tines for Wear

Removing and Replacing A Tine Holder Assembly

Single Tine Replacement

Removing Tine Holder Assembly

Replacing Tines Holder Assembly

Tire and Wheel Maintenance

Tine Shaft Maintenance

Air Cleaner Maintenance

Spark Plug Maintenance

Testing the Forward Interlock Wiring System

Inspecting Forward Interlock Wiring System

Storing Your Tiller

Troubleshooting Procedures

Appendix A Troubleshooting

PROBLEM

CHECK OR TEST

5 Tines Turn, But Wheels Won’t

See Troubleshooting the Forward Interlock Safety System in Section

Wheel Weights

Appendix B Attachments & Accessories

Troy-Bilt PTO Log Splitter

Dozer/Snow Blade Attachment

WHEELS/TINES/PTO DRIVE LEVER & YOKE ASSEMBLY

6 Parts List

PART

DESCRIPTION

FORWARD INTERLOCK SYSTEM

Parts List

HANDLEBAR ASSEMBLY

DEPTH REGULATOR & TINE HOOD ASSEMBLIES

See Page See Page

WHEEL SPEED LEVER, BELT DRIVE SYSTEM, ENGINES, WHEELS

BELT DRIVE SYSTEM

WHEEL SPEED LEVER

ENGINES AND ENGINE MOUNT

WHEEL & TIRE ASSEMBLIES

POWER UNIT TRANSMISSION ASSEMBLIES

PINION SHAFT ASSEMBLY

DRIVE SHAFT ASSEMBLY

BRACKET ASSEMBLIES

continued on page

MODELS 682J & E682L

POWER UNIT TRANSMISSION ASSEMBLIES Continued from page

TRANSMISSION ASSEMBLY

TRANSMISSION HOUSING

MISCELLANEOUS PARTS

NOTE 1 THESE SCREWS HAVE A SPECIAL SEALING DESIGN

TILLER ATTACHMENT TRANSMISSION ASSEMBLIES

THAT CAN NOT BE REUSED WITHOUT RISKING THE

LOSS OF TRANSMISSION OIL. IF THESE SCREWS

TRANSMISSION HOUSING AND DIPSTICK

TILLER DRIVE SHAFT ASSEMBLY

BOLO TINE ASSEMBLIES

CUSTOM TILLING TINES

MODEL E682L

ELECTRIC START SYSTEM

PART

BUMPER ATTACHMENT

Page

Page

Page

TROY-BILT LLC, P.O. Box 361131, Cleveland, Ohio

TROY-BILT TILLER LIFETIME LIMITED WARRANTY