Vermont Castings Madison

Wall Shields

Wall shields should be constructed of 24 gauge or heavier sheet metal, or another noncombustible mate- rial such as 1/2” (13mm) insulation board (Fig. 14) or common brick “laid on flat,” with the 3¹⁄₂" (89mm) side down.

Shields must be spaced out from the combustible sur- face 1" (25mm) on noncombustible spacers. The spac- ers should not be directly behind the stove or chimney connector.

Air must be able to flow between the wall and the shield. At least 50% of the bottom 1" (25mm) of the shield should be open and the shield must be open at the top.

Air flow |

|

Stud wall |

|

framing |

|

Wall shield |

|

Noncombustible |

|

spacers and | Shield |

fasteners |

|

Drywall | Metal Spacer |

|

Air flow

ST248a

Fig. 14 Approved Wall shield construction

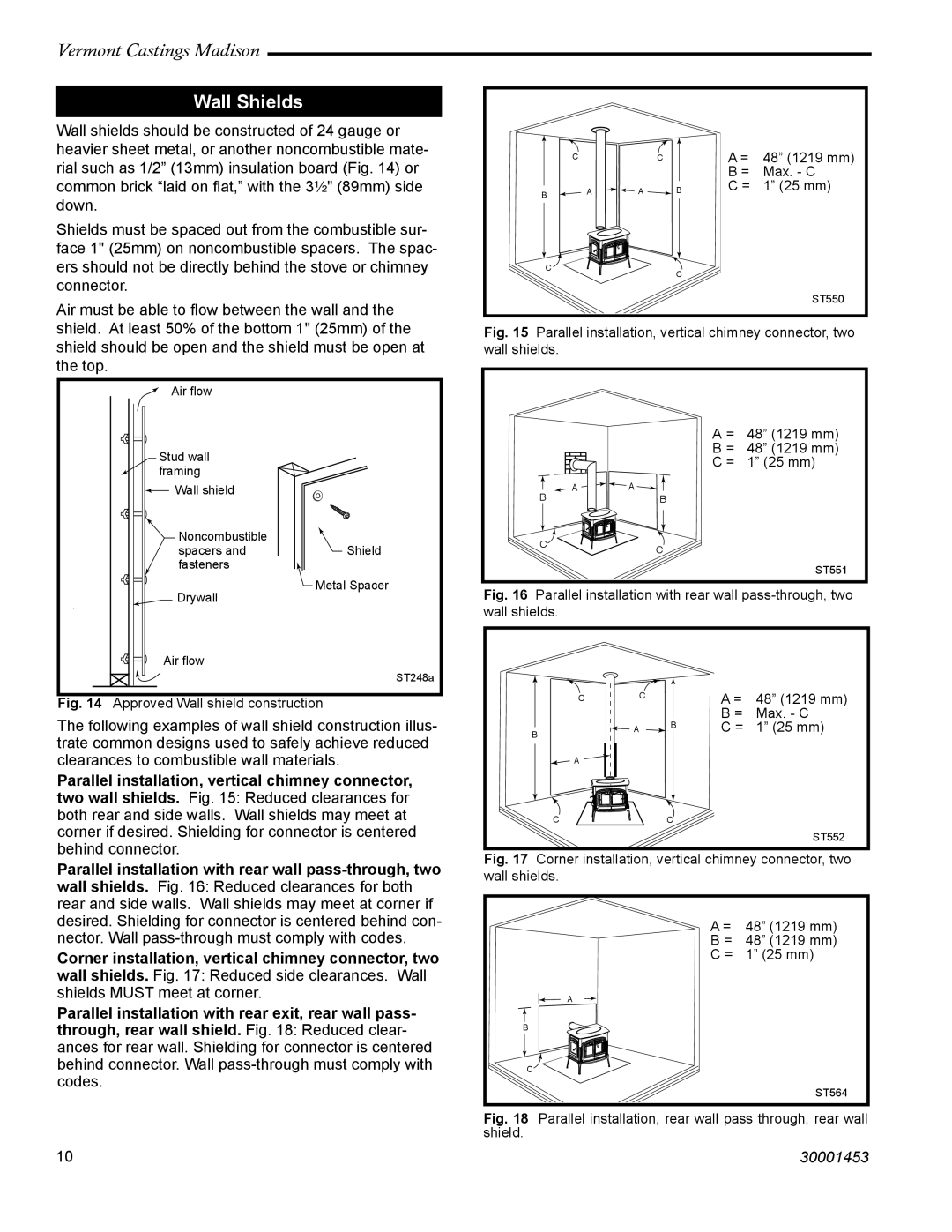

The following examples of wall shield construction illus- trate common designs used to safely achieve reduced clearances to combustible wall materials.

Parallel installation, vertical chimney connector, two wall shields. Fig. 15: Reduced clearances for both rear and side walls. Wall shields may meet at corner if desired. Shielding for connector is centered behind connector.

Parallel installation with rear wall

Corner installation, vertical chimney connector, two wall shields. Fig. 17: Reduced side clearances. Wall shields MUST meet at corner.

Parallel installation with rear exit, rear wall pass- through, rear wall shield. Fig. 18: Reduced clear- ances for rear wall. Shielding for connector is centered behind connector. Wall

|

| C | C |

| A = | 48” (1219 mm) |

|

|

|

|

| B = | Max. - C |

| B | A | A | B | C = 1” (25 mm) | |

|

|

| ||||

|

|

|

|

|

| |

| C |

|

| C |

|

|

|

|

|

|

|

| |

|

|

|

|

|

| ST550 |

Fig. 15 | Parallel installation, vertical chimney connector, two | |||||

wall shields.

|

| A = | 48” (1219 mm) |

|

| B = | 48” (1219 mm) |

|

| C = 1” (25 mm) | |

| A | A |

|

| B | B |

|

| C | C |

|

|

|

| |

|

|

| ST551 |

Fig. 16 | Parallel installation with rear wall | ||

wall shields.

| C | C |

| A = | 48” (1219 mm) |

|

|

| B | B = | Max. - C |

| B | A | C = | 1” (25 mm) | |

|

|

|

|

| |

| A |

|

|

|

|

| C |

| C |

|

|

|

|

|

|

| ST552 |

Fig. 17 | Corner installation, vertical chimney connector, two | ||||

wall shields.

A = | 48” (1219 mm) |

B = 48” (1219 mm) | |

C = 1” (25 mm) | |

A |

|

B |

|

C |

|

| ST564 |

Fig. 18 Parallel installation, rear wall pass through, rear wall shield.

10 | 30001453 |