DVRTSB Bay Window Fireplace

Maintenance

Burner and Burner Compartment

It is important to keep the burner and the burner compartment clean. At least once per year the logs and lava rock/ember material should be removed and the burner compartment vacuumed and wiped out. Remove and replace the logs as per the instructions in this manual.

Always handle the logs with care as they are fragile and may also be hot if the

![]() fireplace has been in use. FK24/FK12 Fan Assembly

fireplace has been in use. FK24/FK12 Fan Assembly

The fan unit requires periodic cleaning. At least once per month in the operating season, open the lower louvre panels and wipe or vacuum the area around the fan to remove any build up of dust or lint.

Brass Trim

Clean the brass trim pieces using a soft cloth lightly dampened with lemon oil. Do not use water or household cleaners on any brass components.

Contact your local representative to arrange an annual service program.

Cleaning the Standing

Pilot Control System

The burner and control system consists of

• burner tube | • gas orifice |

• pilot assembly | • thermopile |

•millivolt gas valve

Most of these components may require only an oc- casional checkup and cleaning and some may require adjustment. If repair is necessary, it should be per- formed by a qualified technician.

Logs May Be HOT!!

Logs May Be HOT!!

1.Turn off pilot light at gas valve side.

2.Let fireplace cool if it has been running.

3.Remove window frame assembly. (Refer to Window Frame Assembly Removal section)

4.Remove logs.

5.Vacuum burner compartment especially around orifice primary air openings.

6.Visually inspect pilot. Brush or blow away any dust or lint accumulation.

7.Reinstall logs.

8.Ignite pilot - Refer to Lighting Instructions.

9.Reinstall window frame assembly.

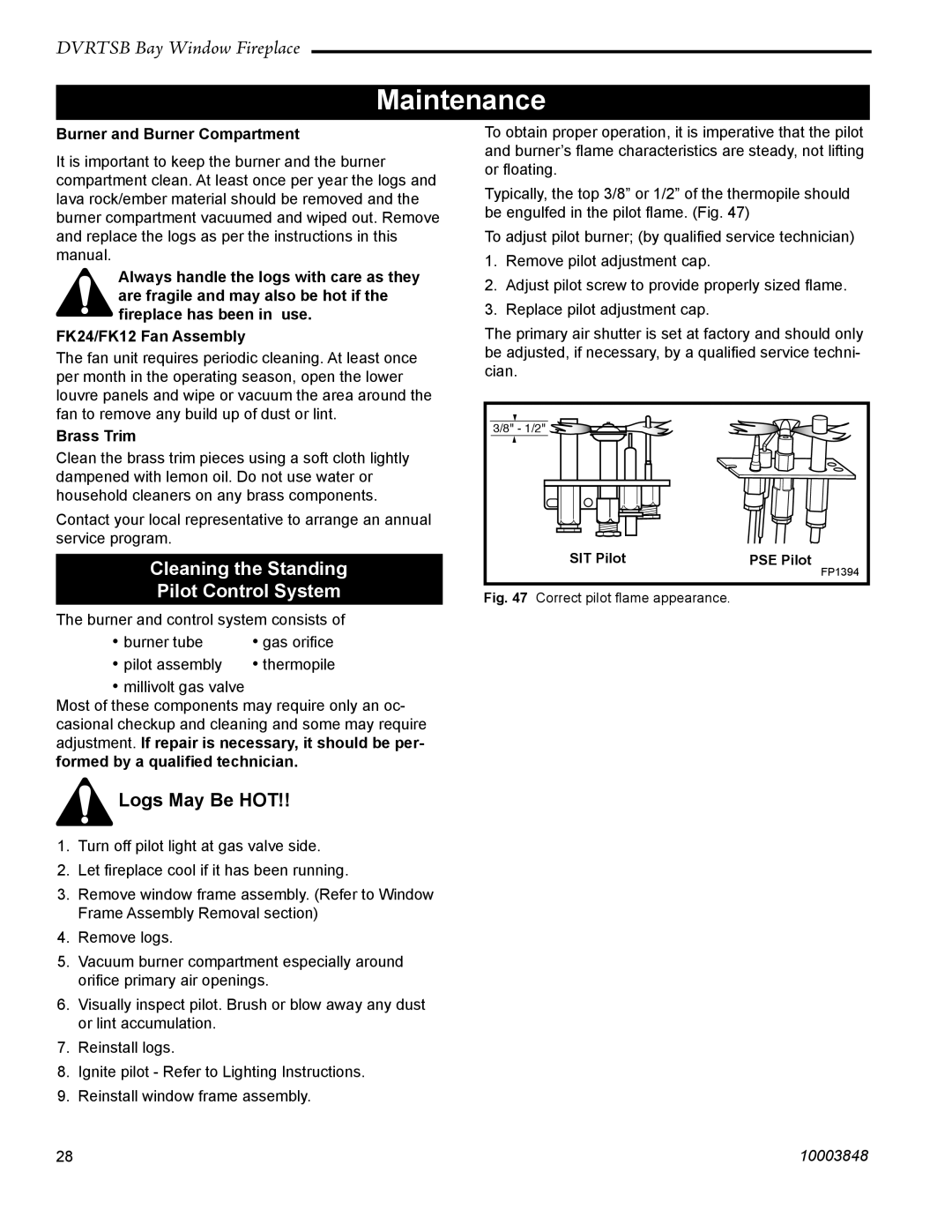

To obtain proper operation, it is imperative that the pilot and burner’s flame characteristics are steady, not lifting or floating.

Typically, the top 3/8” or 1/2” of the thermopile should be engulfed in the pilot flame. (Fig. 47)

To adjust pilot burner; (by qualified service technician)

1.Remove pilot adjustment cap.

2.Adjust pilot screw to provide properly sized flame.

3.Replace pilot adjustment cap.

The primary air shutter is set at factory and should only be adjusted, if necessary, by a qualified service techni- cian.

3/8" - 1/2" |

| |

| SIT Pilot | PSE Pilot |

|

| FP1394 |

Fig. 47 | Correct pilot flame appearance. |

|

28 | 10003848 |