plicable. When using the unitized 30°, 45° or 90° elbows, apply 1/4” bead of high temperature, 550°F or higher, sealant (milpack or stove cement) to the joint of the inner pipe (flue pipe) and the straight section as it is impossi- ble to be taped. The outer pipe must be taped with 315°F high temperature metal adhesive tape for proper sealing.

For vertically venting either propane or natural gas units, with vertical vent heights of 12’ (3.7m) or greater, (measured from the top of the flue collar) the flue restrictor plate as supplied with this unit should be used. (Fig. 29) Refer to Figure 28 for flue restrictor plate installation.

X

FP1461

Fig. 29 Flue restrictor plate use in straight up installation.

For LP gas venting straight vertical with 20’ (6 m) or more, adjust the primary air to the burner housing as well as the fresh air to the unit by doing the following:

1.Remove glass, logs, glowing embers (if installed).

2.Remove andirons, fettles and burner housing.

3.Remove the two (2) screws securing the deflector and the rectangular restrictor plate in place. (Fig. 30) Turn the restrictor plate around so the body of the plate will extend down over the air opening.

Rectangular Restrictor Plate |

Deflector |

Screws

FP1615

Fig. 30 Turn rectangular restrictor plate over to partially cover opening.

20011957

Chateau™ Direct Vent Gas Fireplace

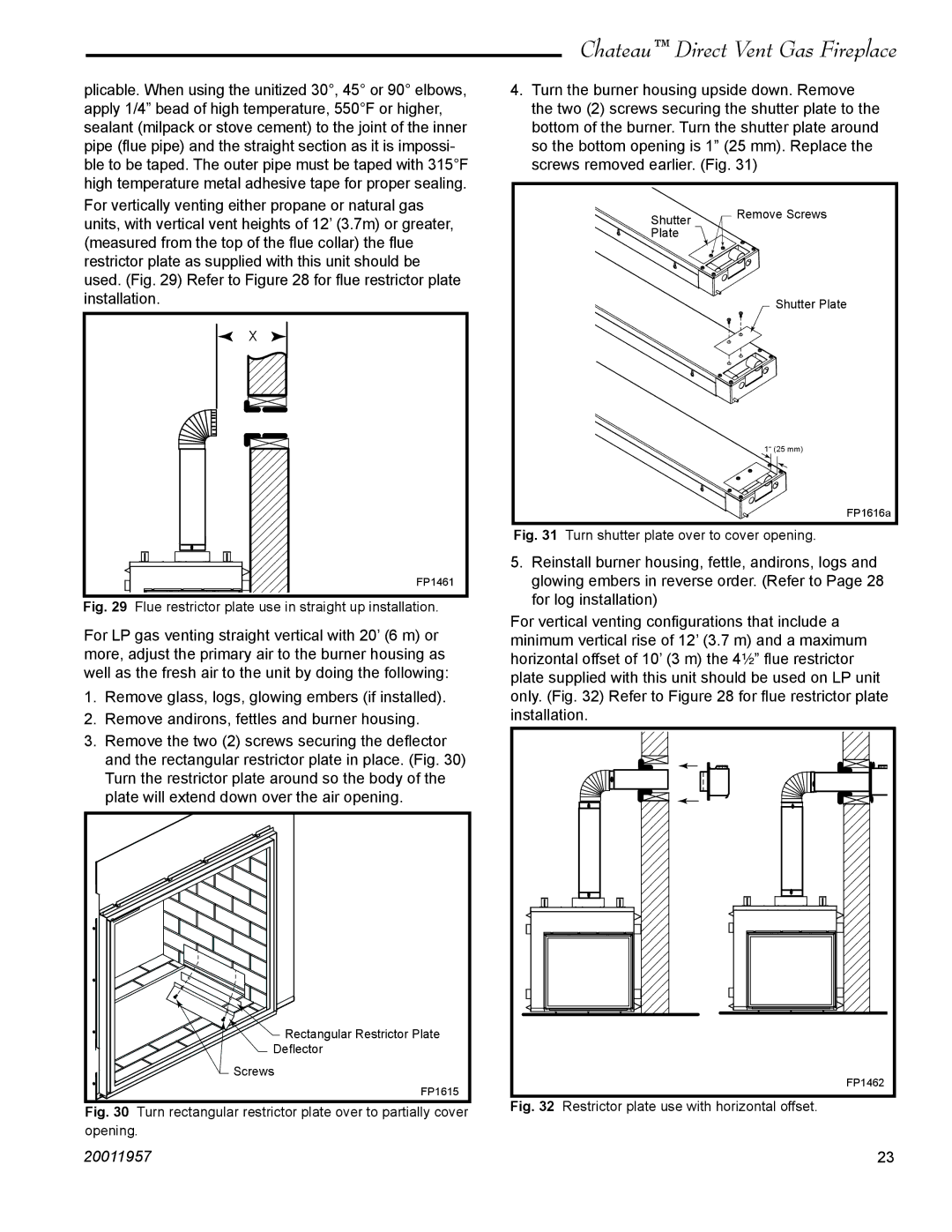

4.Turn the burner housing upside down. Remove the two (2) screws securing the shutter plate to the bottom of the burner. Turn the shutter plate around so the bottom opening is 1” (25 mm). Replace the screws removed earlier. (Fig. 31)

Shutter | Remove Screws |

| |

Plate |

|

| Shutter Plate |

1“ (25 mm)

FP1616a

Fig. 31 Turn shutter plate over to cover opening.

5.Reinstall burner housing, fettle, andirons, logs and glowing embers in reverse order. (Refer to Page 28 for log installation)

For vertical venting configurations that include a minimum vertical rise of 12’ (3.7 m) and a maximum horizontal offset of 10’ (3 m) the 4¹⁄₂” flue restrictor plate supplied with this unit should be used on LP unit only. (Fig. 32) Refer to Figure 28 for flue restrictor plate installation.

| FP1462 |

Fig. 32 | Restrictor plate use with horizontal offset. |

| 23 |