Chateau™ Direct Vent Gas Fireplace

22.Turn on gas supply and operate valve with remote control as needed to indicate gas pressure. The manifold pressure for LP should be approximately 10.0” wcp.

CAUTION: Turn off the valve and gas supply before removing test port adaptor and replac- ing plug.

23.After test, remove adaptor and replace plug.

24.Turn on gas supply and check that plugs are tight and leak free.

25.Follow instructions in Homeowner’s Manual to

26.Replace glass frame.

27.Conversion complete.

Pilot Flame Adjustment

Typically, the top 3/8” or 1/2” of the pilot flame sensor should be engulfed in the pilot flame. (Page 32, Fig. 51)

To adjust pilot burner:

1.Locate pilot adjustment screw on the valve next to the black plastic cap. Refer to Page 34.

2.Adjust pilot screw to provide proper sized flame. Only a small adjustment should be needed.

NOTE: Do not rotate screw excessively. Do not adjust any other screws on the valve.

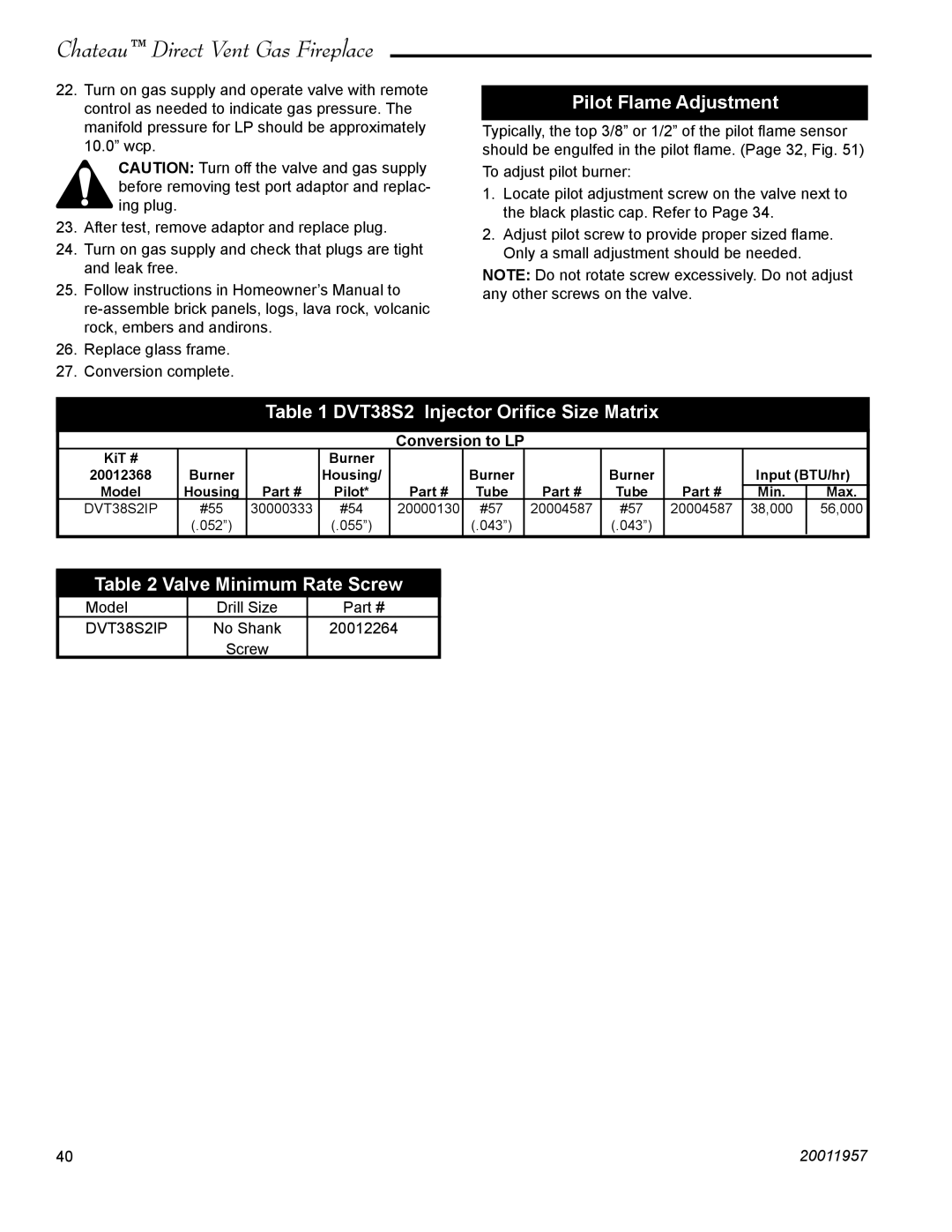

Table 1 DVT38S2 Injector Orifice Size Matrix

Conversion to LP

KiT # |

|

| Burner |

|

|

|

|

|

|

|

20012368 | Burner |

| Housing/ |

| Burner |

| Burner |

| Input (BTU/hr) | |

Model | Housing | Part # | Pilot* | Part # | Tube | Part # | Tube | Part # | Min. | Max. |

DVT38S2IP | #55 | 30000333 | #54 | 20000130 | #57 | 20004587 | #57 | 20004587 | 38,000 | 56,000 |

| (.052”) |

| (.055”) |

| (.043”) |

| (.043”) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 2 Valve Minimum Rate Screw

Model | Drill Size | Part # |

DVT38S2IP | No Shank | 20012264 |

| Screw |

|

40 | 20011957 |