Stardance Direct Vent/Natural Vent Gas Heater

Maintenance

Your Stardance Gas Heater will provide years of service with minimal upkeep. The following procedures will help ensure that your stove continues to function properly.

Annual System Inspection

Have the entire heater and venting system inspected annually by a qualified gas technician. Replace any worn or broken parts.

Logset and Burner /

Cleaning and Inspection

Cleanliness is critical to the proper function of the heater. The logset and burner must all be kept free of dust and unobstructed by debris. Inspect these areas before each use and clean as necessary.

1.Turn the burner OFF and let the heater cool com- pletely before cleaning.

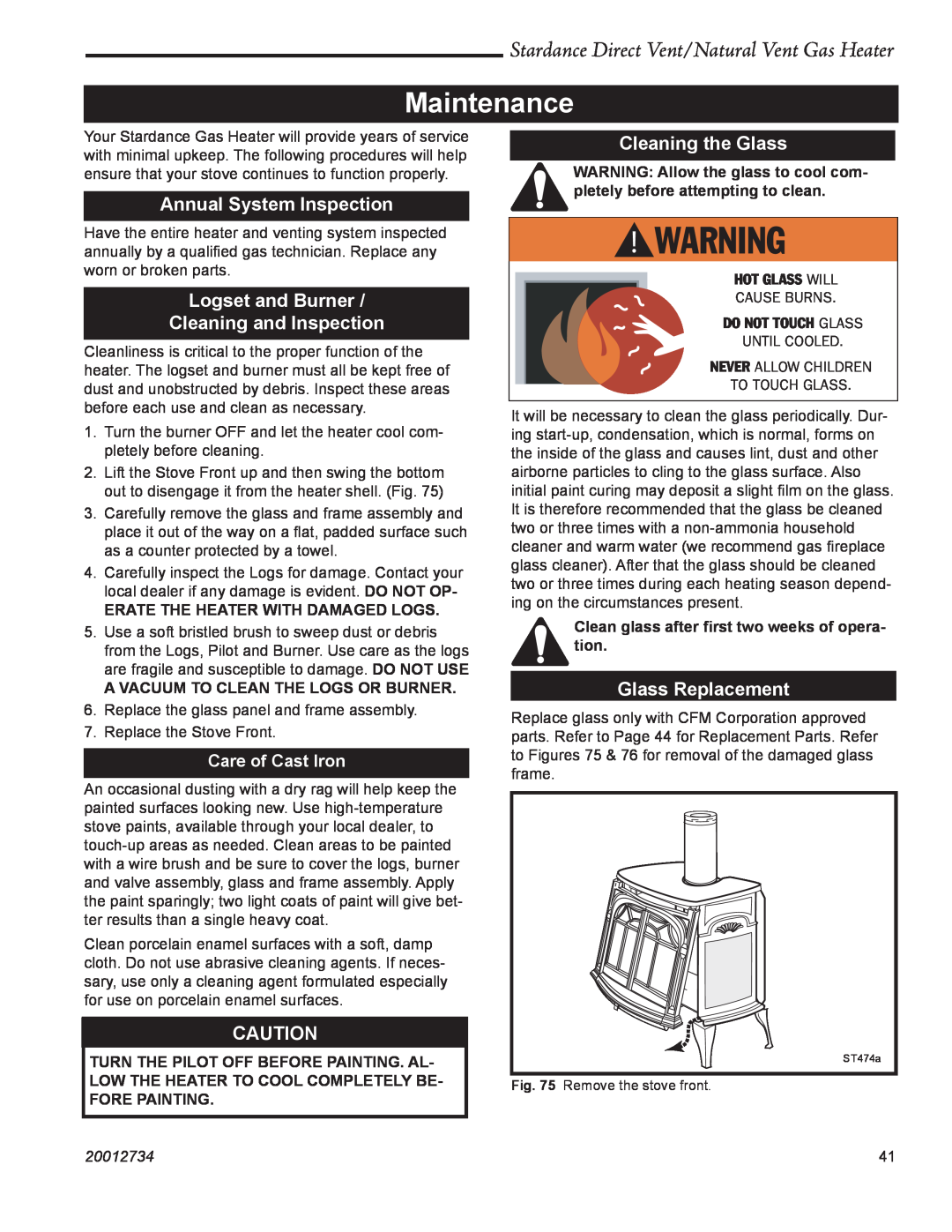

2.Lift the Stove Front up and then swing the bottom out to disengage it from the heater shell. (Fig. 75)

3.Carefully remove the glass and frame assembly and place it out of the way on a flat, padded surface such as a counter protected by a towel.

4.Carefully inspect the Logs for damage. Contact your local dealer if any damage is evident. DO NOT OP-

ERATE THE HEATER WITH DAMAGED LOGS.

5.Use a soft bristled brush to sweep dust or debris from the Logs, Pilot and Burner. Use care as the logs are fragile and susceptible to damage. DO NOT USE

A VACUUM TO CLEAN THE LOGS OR BURNER.

6.Replace the glass panel and frame assembly.

7.Replace the Stove Front.

Care of Cast Iron

An occasional dusting with a dry rag will help keep the painted surfaces looking new. Use

Clean porcelain enamel surfaces with a soft, damp cloth. Do not use abrasive cleaning agents. If neces- sary, use only a cleaning agent formulated especially for use on porcelain enamel surfaces.

CAUTION

TURN THE PILOT OFF BEFORE PAINTING. AL- LOW THE HEATER TO COOL COMPLETELY BE- FORE PAINTING.

Cleaning the Glass

WARNING: Allow the glass to cool com- pletely before attempting to clean.

��������

��������������

������������

������������������

�������������

��������������������

���������������

It will be necessary to clean the glass periodically. Dur- ing

Clean glass after first two weeks of opera- tion.

Glass Replacement

Replace glass only with CFM Corporation approved parts. Refer to Page 44 for Replacement Parts. Refer to Figures 75 & 76 for removal of the damaged glass frame.

ST474a

Fig. 75 Remove the stove front.

20012734 | 41 |