Stardance Direct Vent/Natural Vent Gas Heater

#7DVAIS Attic Insulation Shield

Use Four | #7DVFS |

8dNails | Firestop in |

| Upper Floor |

|

| #7DVFS |

ST222 |

| Firestop in |

| Ceiling | |

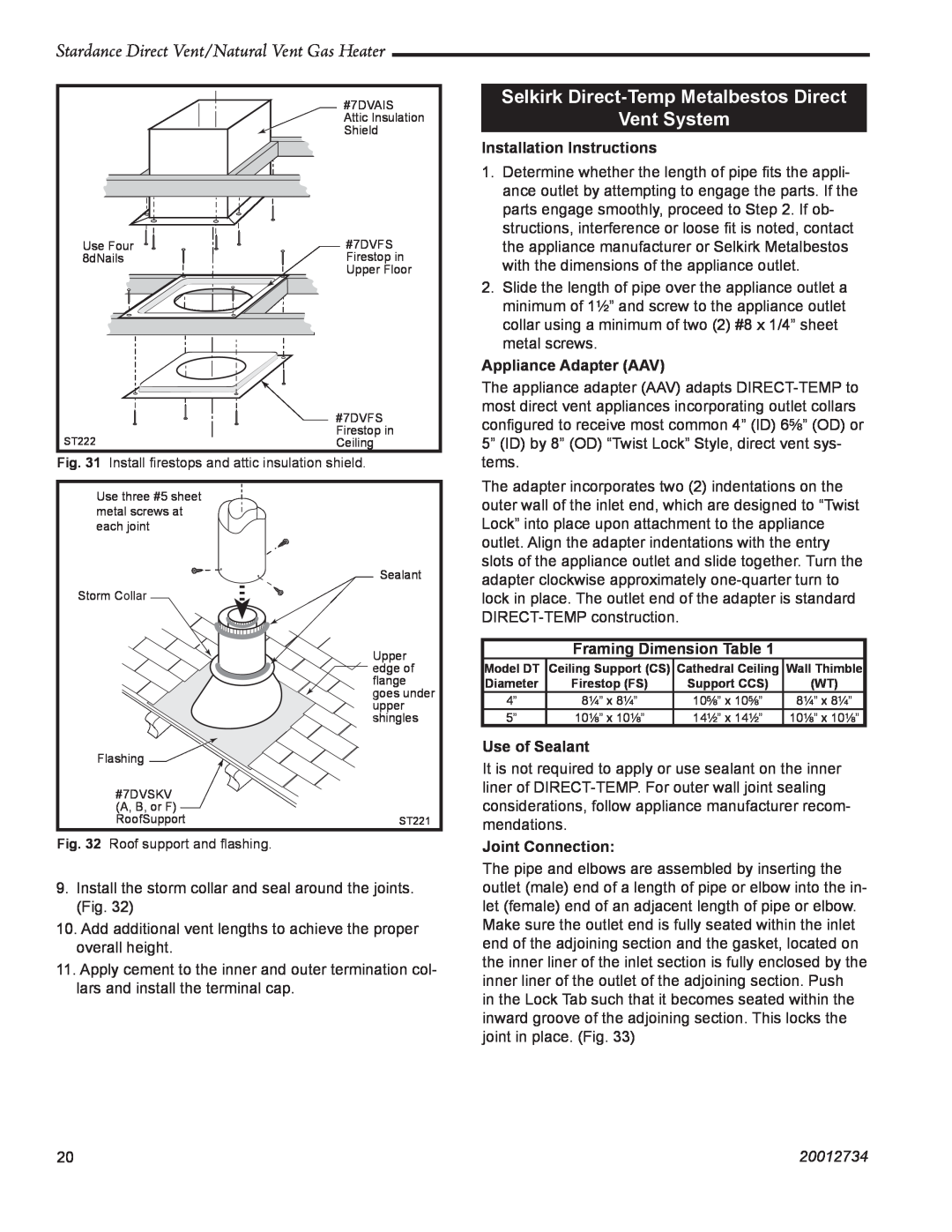

Fig. 31 | Install firestops and attic insulation shield. | |

Use three #5 sheet |

| |

metal screws at |

| |

each joint |

| |

|

| Sealant |

Storm Collar |

| |

|

| Upper |

|

| edge of |

|

| flange |

|

| goes under |

|

| upper |

|

| shingles |

Flashing |

| |

| #7DVSKV |

|

| (A, B, or F) |

|

| RoofSupport | ST221 |

Fig. 32 | Roof support and flashing. |

|

9.Install the storm collar and seal around the joints. (Fig. 32)

10.Add additional vent lengths to achieve the proper overall height.

11.Apply cement to the inner and outer termination col- lars and install the terminal cap.

Selkirk Direct-Temp Metalbestos Direct

Vent System

Installation Instructions

1.Determine whether the length of pipe fits the appli- ance outlet by attempting to engage the parts. If the parts engage smoothly, proceed to Step 2. If ob- structions, interference or loose fit is noted, contact the appliance manufacturer or Selkirk Metalbestos with the dimensions of the appliance outlet.

2.Slide the length of pipe over the appliance outlet a minimum of 1¹⁄₂” and screw to the appliance outlet collar using a minimum of two (2) #8 x 1/4” sheet metal screws.

Appliance Adapter (AAV)

The appliance adapter (AAV) adapts

The adapter incorporates two (2) indentations on the outer wall of the inlet end, which are designed to “Twist Lock” into place upon attachment to the appliance outlet. Align the adapter indentations with the entry slots of the appliance outlet and slide together. Turn the adapter clockwise approximately

Framing Dimension Table 1

Model DT | Ceiling Support (CS) | Cathedral Ceiling | Wall Thimble |

Diameter | Firestop (FS) | Support CCS) | (WT) |

4” | 8¹⁄₄” x 8¹⁄₄” | 10⁵⁄₈” x 10⁵⁄₈” | 8¹⁄₄” x 8¹⁄₄” |

5” | 10¹⁄₈” x 10¹⁄₈” | 14¹⁄₂” x 14¹⁄₂” | 10¹⁄₈” x 10¹⁄₈” |

Use of Sealant

It is not required to apply or use sealant on the inner liner of

Joint Connection:

The pipe and elbows are assembled by inserting the outlet (male) end of a length of pipe or elbow into the in- let (female) end of an adjacent length of pipe or elbow. Make sure the outlet end is fully seated within the inlet end of the adjoining section and the gasket, located on the inner liner of the inlet section is fully enclosed by the inner liner of the outlet of the adjoining section. Push in the Lock Tab such that it becomes seated within the inward groove of the adjoining section. This locks the joint in place. (Fig. 33)

20 | 20012734 |