WFAE-55F specifications

The Wells WFAE-55F is a high-performance commercial fryer that exemplifies efficiency and versatility in the culinary industry. Designed to meet the rigorous demands of restaurants and food service operations, the WFAE-55F stands out with its robust features and innovative technology.One of the notable characteristics of the WFAE-55F is its powerful dual heating system. This fryer operates with a combination of high-performance gas burners and an advanced convection technology, ensuring that food is cooked evenly and efficiently. The unit provides fast recovery times, enabling chefs to prepare large quantities of food without compromising quality.

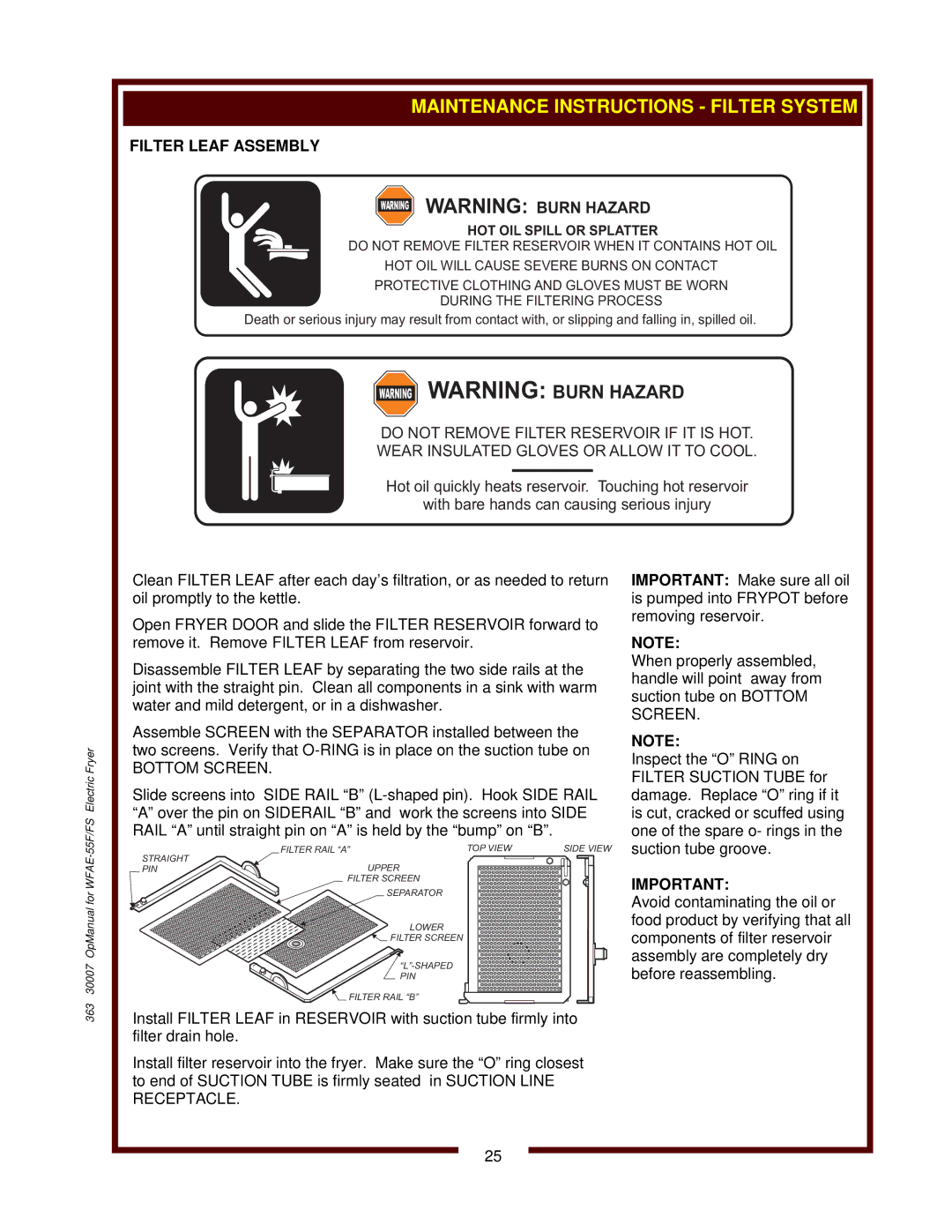

The WFAE-55F comes equipped with a generous oil capacity, allowing for cooking multiple menu items simultaneously without significant drops in oil temperature. This feature is particularly beneficial during peak service times, enhancing productivity in busy kitchens. The fryer’s oil filtration system is another standout feature, providing a simple and effective way to maintain oil quality, extending the life of the oil, and ensuring consistently great-tasting food while reducing operational costs.

Durability is a hallmark of the Wells WFAE-55F, constructed from high-grade stainless steel, which is resistant to corrosion and easy to clean. This design not only contributes to the longevity of the fryer but also helps in maintaining hygiene standards in commercial kitchens. The fryer is also designed with safety in mind, featuring a secure fry pot design to minimize spills and accidents.

User-friendly controls are also a part of the WFAE-55F’s appeal. The fryer features intuitive electronic controls that provide precise temperature management and monitoring, allowing chefs to set the desired cooking temperatures accurately. Additionally, the adjustable legs allow for versatility in installation, accommodating various kitchen layouts.

In terms of energy efficiency, the WFAE-55F is designed to minimize gas consumption while maximizing cooking performance. This not only reduces environmental impact but also helps businesses save on energy bills.

Overall, the Wells WFAE-55F is an exemplary model in commercial fryers, combining strength, efficiency, and advanced technology to meet the ever-evolving needs of the food service industry. Whether frying, sautéing, or preparing a variety of dishes, the WFAE-55F is a reliable companion in the kitchen that meets the high standards of professionals.