I N S T A L L A T I O N

G A S S U P P L Y

R E Q U I R E M E N T S

![]() WARNING

WARNING

EXPLOSION HAZARD –

•Use a new CSA approved gas supply line and install a gas

•Securely tighten all gas con- nections.

•If connected to LP, have a qualified person make sure gas pressure does not exceed 14 inches water column.

•Failure to do so can result in explosion, fire or death.

IMPORTANT NOTE: Observe all governing codes and ordinances.

IMPORTANT NOTE: Range must be connected to a regulated gas supply.

•This installation must conform with local codes and ordinances. In the absence of local codes, installations must conform with American National Standard, National Fuel Gas Code ANSI Z223.1 – latest edition or CANI – B149.1 or 2.

•The range is equipped for use with natural gas or LP. It is design certified by the Canadian Standards Association (CSA) for natural or LP gases. The model / serial rating plate, located on the bottom of the control panel assembly just above the oven door on the far right, has information on the type of gas that should be used. If this information does not agree with the type of gas available, check with the local gas supplier.

•Provide a gas supply line of 3/4" rigid pipe to the range location. A smaller size pipe on long runs may result in insufficient gas supply. Pipe joint compounds, suitable for use with LP gas should be used. For LP gas, piping or tubing size can be 1/2" minimum. LP gas suppliers usually determine the size and materials used on the system.

•If local codes permit, a new CSA

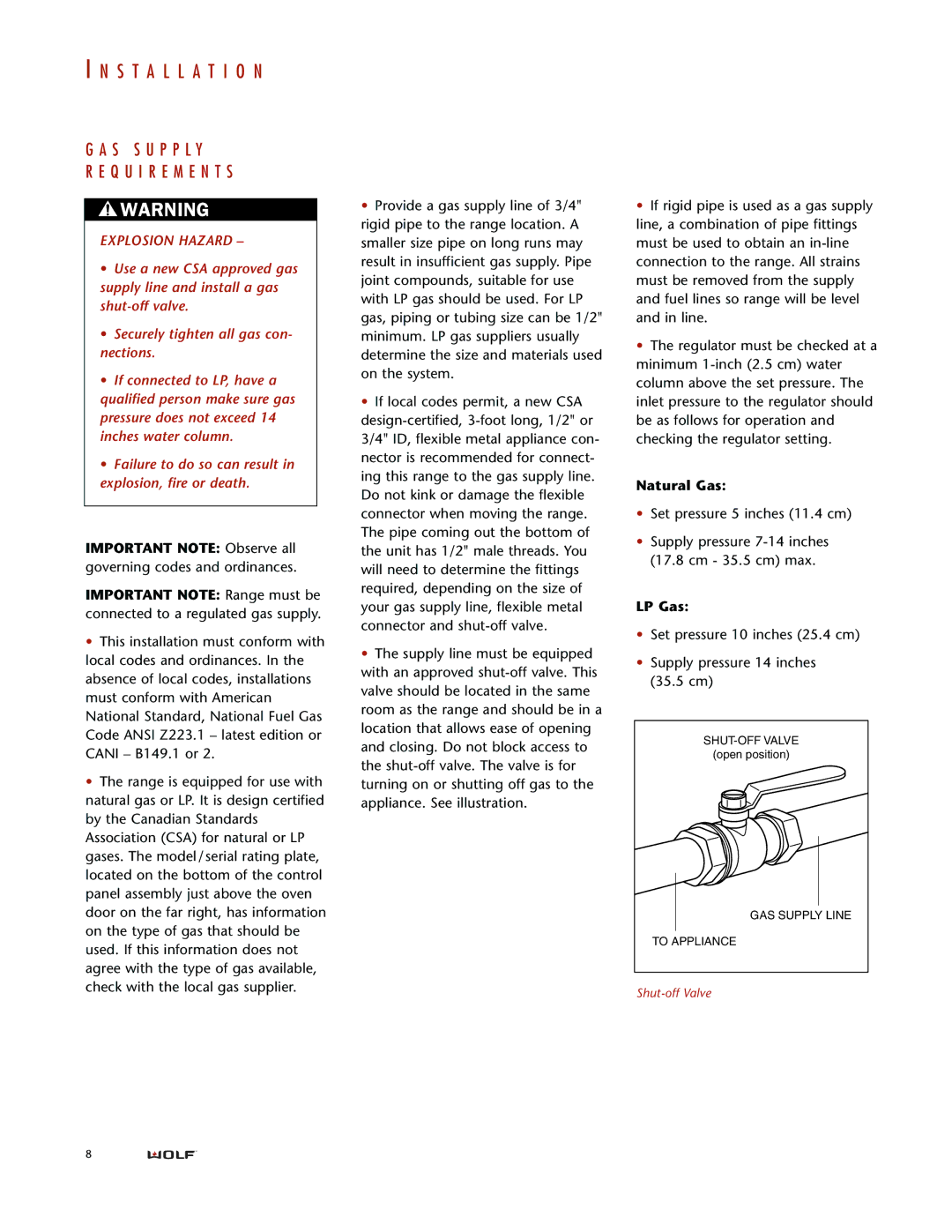

•The supply line must be equipped with an approved

•If rigid pipe is used as a gas supply line, a combination of pipe fittings must be used to obtain an

•The regulator must be checked at a minimum

Natural Gas:

•Set pressure 5 inches (11.4 cm)

•Supply pressure

LP Gas:

•Set pressure 10 inches (25.4 cm)

•Supply pressure 14 inches (35.5 cm)

(open position) |

GAS SUPPLY LINE |

TO APPLIANCE |

8