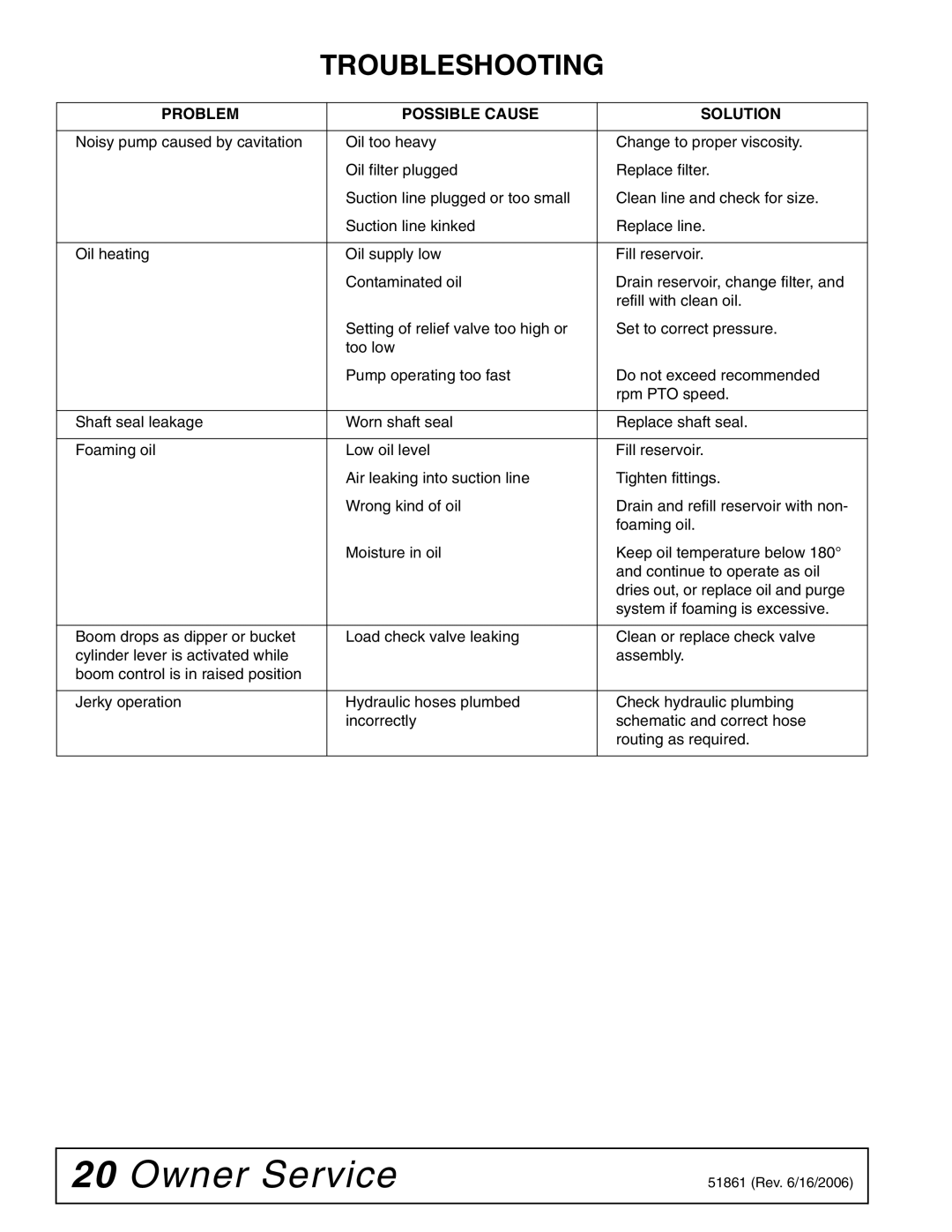

TROUBLESHOOTING

PROBLEM | POSSIBLE CAUSE | SOLUTION |

|

|

|

Noisy pump caused by cavitation | Oil too heavy | Change to proper viscosity. |

| Oil filter plugged | Replace filter. |

| Suction line plugged or too small | Clean line and check for size. |

| Suction line kinked | Replace line. |

|

|

|

Oil heating | Oil supply low | Fill reservoir. |

| Contaminated oil | Drain reservoir, change filter, and |

|

| refill with clean oil. |

| Setting of relief valve too high or | Set to correct pressure. |

| too low |

|

| Pump operating too fast | Do not exceed recommended |

|

| rpm PTO speed. |

|

|

|

Shaft seal leakage | Worn shaft seal | Replace shaft seal. |

|

|

|

Foaming oil | Low oil level | Fill reservoir. |

| Air leaking into suction line | Tighten fittings. |

| Wrong kind of oil | Drain and refill reservoir with non- |

|

| foaming oil. |

| Moisture in oil | Keep oil temperature below 180° |

|

| and continue to operate as oil |

|

| dries out, or replace oil and purge |

|

| system if foaming is excessive. |

|

|

|

Boom drops as dipper or bucket | Load check valve leaking | Clean or replace check valve |

cylinder lever is activated while |

| assembly. |

boom control is in raised position |

|

|

|

|

|

Jerky operation | Hydraulic hoses plumbed | Check hydraulic plumbing |

| incorrectly | schematic and correct hose |

|

| routing as required. |

|

|

|

20 Owner Service | 51861 (Rev. 6/16/2006) |

|

|