Contamination will shorten the life of hydraulic system components. Change oil and filter after first 20 hours of operation and then every 200 hours of operation.

ENGAGE PTO AND RUN AT IDLE FOR 5 MINUTES, THEN CHECK OIL LEVEL. Add Fluid as necessary.

Position backhoe on level surface. Back tractor up as near as possible to center of backhoe. Refer to Figure 23 and select a pump mounting that will work on you specific tractor.

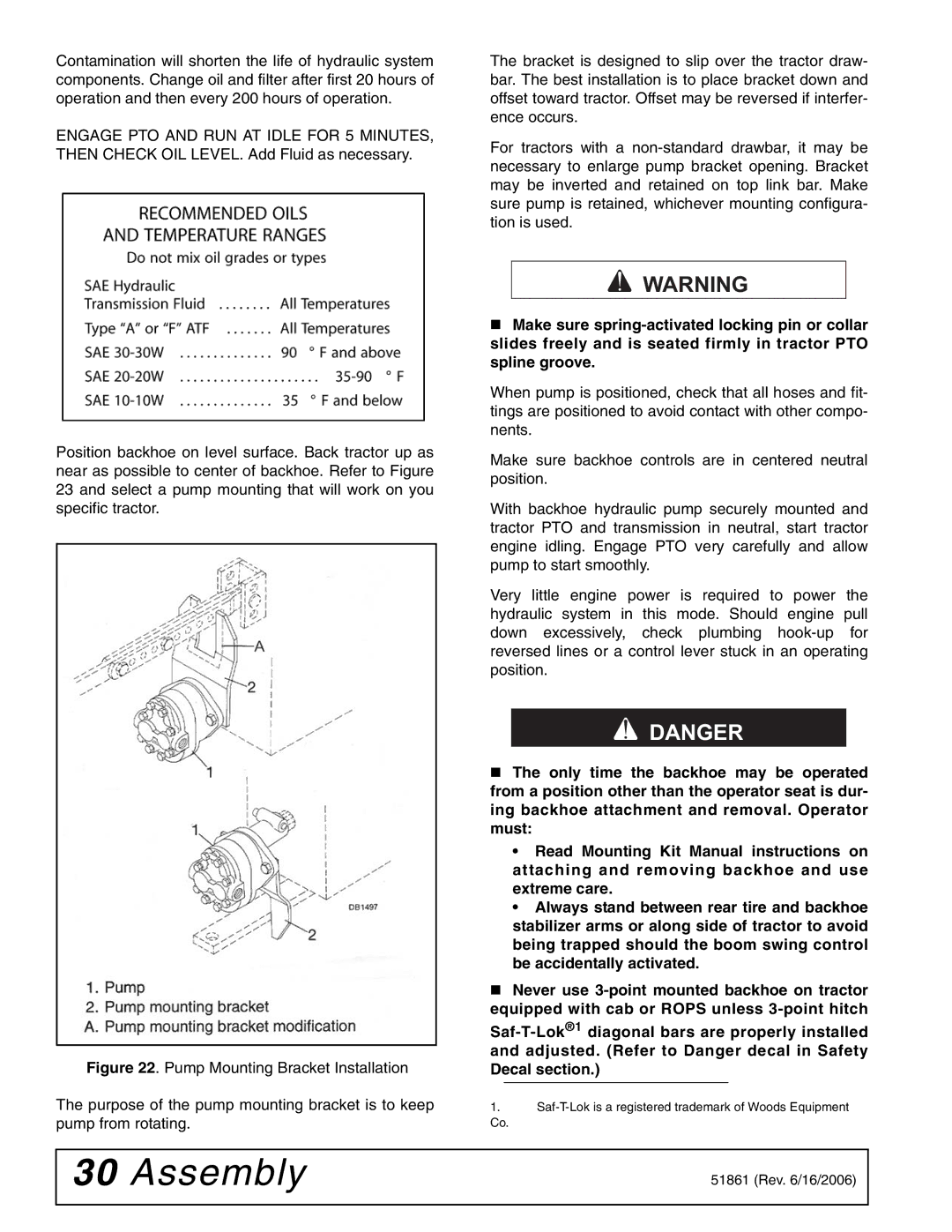

Figure 22. Pump Mounting Bracket Installation

The purpose of the pump mounting bracket is to keep pump from rotating.

The bracket is designed to slip over the tractor draw- bar. The best installation is to place bracket down and offset toward tractor. Offset may be reversed if interfer- ence occurs.

For tractors with a non-standard drawbar, it may be necessary to enlarge pump bracket opening. Bracket may be inverted and retained on top link bar. Make sure pump is retained, whichever mounting configura- tion is used.

A WARNING

Make sure

When pump is positioned, check that all hoses and fit- tings are positioned to avoid contact with other compo- nents.

Make sure backhoe controls are in centered neutral position.

With backhoe hydraulic pump securely mounted and tractor PTO and transmission in neutral, start tractor engine idling. Engage PTO very carefully and allow pump to start smoothly.

Very little engine power is required to power the hydraulic system in this mode. Should engine pull down excessively, check plumbing

A DANGER

The only time the backhoe may be operated from a position other than the operator seat is dur- ing backhoe attachment and removal. Operator must:

•Read Mounting Kit Manual instructions on attaching and removing backhoe and use extreme care.

•Always stand between rear tire and backhoe stabilizer arms or along side of tractor to avoid being trapped should the boom swing control be accidentally activated.

Never use

1.Saf-T-Lok is a registered trademark of Woods Equipment

Co.

30 Assembly | 51861 (Rev. 6/16/2006) |

|

|