3.Align crossbar (8) with blade access hole in cutter frame. Apply a liberal coating of Never Seez® or equivalent to blade pin and crossbar hole. Make sure blade offset is away from cutter. Push blade pin through crossbar. Pin should rotate freely prior to installing blade clip (15).

4.Install shims (13 & 16) over blade pin.

NOTE: Only use enough shims to allow keyhole plate (14) to slide into blade pin groove.

5.Install blade clip (15) over keyhole plate and into blade pin groove.

6.Secure into position with cap screw (35). Torque cap screw to 85

7.Repeat steps for opposite side.

NOTE: Blade should be snug but should swivel on pin without having to exert excessive force. Keep any spacers not used in the installation as replace- ments or for future installation.

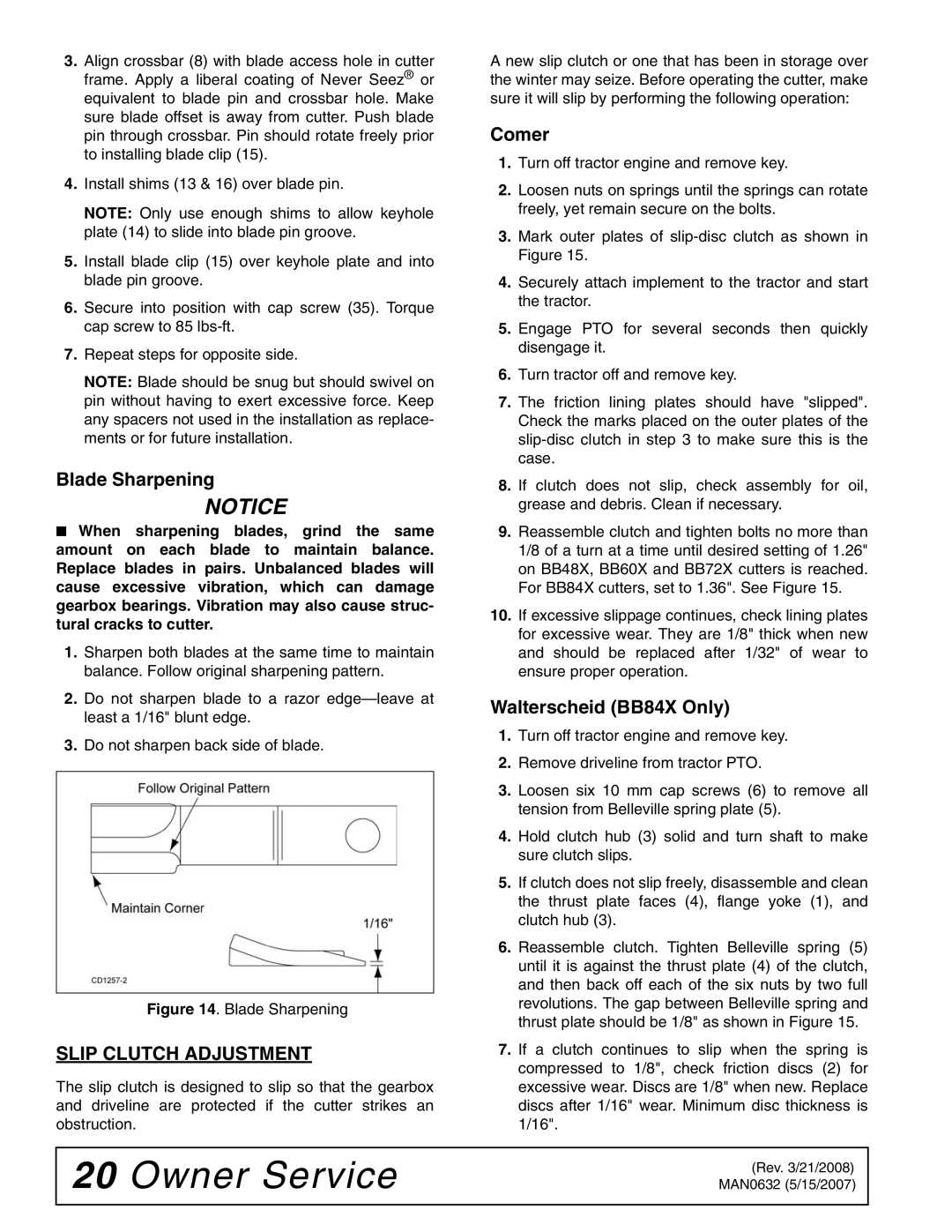

Blade Sharpening

NOTICE

■When sharpening blades, grind the same amount on each blade to maintain balance. Replace blades in pairs. Unbalanced blades will cause excessive vibration, which can damage gearbox bearings. Vibration may also cause struc- tural cracks to cutter.

1.Sharpen both blades at the same time to maintain balance. Follow original sharpening pattern.

2.Do not sharpen blade to a razor

3.Do not sharpen back side of blade.

Figure 14. Blade Sharpening

SLIP CLUTCH ADJUSTMENT

The slip clutch is designed to slip so that the gearbox and driveline are protected if the cutter strikes an obstruction.

A new slip clutch or one that has been in storage over the winter may seize. Before operating the cutter, make sure it will slip by performing the following operation:

Comer

1.Turn off tractor engine and remove key.

2.Loosen nuts on springs until the springs can rotate freely, yet remain secure on the bolts.

3.Mark outer plates of

4.Securely attach implement to the tractor and start the tractor.

5.Engage PTO for several seconds then quickly disengage it.

6.Turn tractor off and remove key.

7.The friction lining plates should have "slipped". Check the marks placed on the outer plates of the

8.If clutch does not slip, check assembly for oil, grease and debris. Clean if necessary.

9.Reassemble clutch and tighten bolts no more than 1/8 of a turn at a time until desired setting of 1.26" on BB48X, BB60X and BB72X cutters is reached. For BB84X cutters, set to 1.36". See Figure 15.

10.If excessive slippage continues, check lining plates for excessive wear. They are 1/8" thick when new and should be replaced after 1/32" of wear to ensure proper operation.

Walterscheid (BB84X Only)

1.Turn off tractor engine and remove key.

2.Remove driveline from tractor PTO.

3.Loosen six 10 mm cap screws (6) to remove all tension from Belleville spring plate (5).

4.Hold clutch hub (3) solid and turn shaft to make sure clutch slips.

5.If clutch does not slip freely, disassemble and clean the thrust plate faces (4), flange yoke (1), and clutch hub (3).

6.Reassemble clutch. Tighten Belleville spring (5) until it is against the thrust plate (4) of the clutch, and then back off each of the six nuts by two full revolutions. The gap between Belleville spring and thrust plate should be 1/8" as shown in Figure 15.

7.If a clutch continues to slip when the spring is compressed to 1/8", check friction discs (2) for excessive wear. Discs are 1/8" when new. Replace discs after 1/16" wear. Minimum disc thickness is 1/16".

20 Owner Service

(Rev. 3/21/2008) MAN0632 (5/15/2007)