Brushbulltm

To the Owner

Introduction

To the Dealer

Table of Contents

BB48X BB60X BB72X BB84X

Specifications

General Information

Free Mower Safety Video

Safety

Woods Equipment Company

Training Package for Rotary Mowers/Cutters-English

Training Package for Rotary Mowers/Cutters-English/Spanish

Safety Rules

Training

Preparation

Operation

Maintenance

Storage

RED Rear Reflector

Safety & Instructional Decals

Serial Number Plate

Be Careful

Crushing and Pinching Hazard

Operation

Operation

Tractor Stability

Attaching Cutter to Tractor BB48X only

Top Link Adjustment BB48X Only

Quick Hitch Attachment BB48X Only

Installation and Removal Driveline Tractor PTO

Attaching Cutter to Tractor BB60X, BB72X, BB84X only

Driveline Attachment

Shortening Driveline

Shredding Material

Cutting Height Adjustment

Driveline Interference Check

PRE-OPERATION Check List

Check Chain Adjustment

Operating Technique

Owner Service

Owner Service

Blocking Method

Lubrication Information

Blade Removal Figure

Blade Installation Figure

Blade Servicing

Slip Clutch Adjustment

Blade Sharpening

Comer

Walterscheid BB84X Only

Walterscheid

Model

Shielding Repair

Driveline Shear Bolt Replacement

Cleaning

Mowing Conditions

Troubleshooting

Problem Possible Cause Solution

Dealer Service

Dealer Service

Gearbox Maintenance

Seal Replacement

Seal Repair

Vertical Shaft Seal Repair

Horizontal Seal Leak Repair

Gearbox Repair

Reinstall Gearbox

Reassemble Gearbox

BB48X, BB60X, BB72X

On CAST/CROWN TOP BB48X, BB60X

BB72X S/N 1159929 and Above only

Reassemble Gearbox Cast Top BB48X

Reassemble Gearbox Cast Top BB60X and BB72X

Crossbar Removal

Crossbar Removal

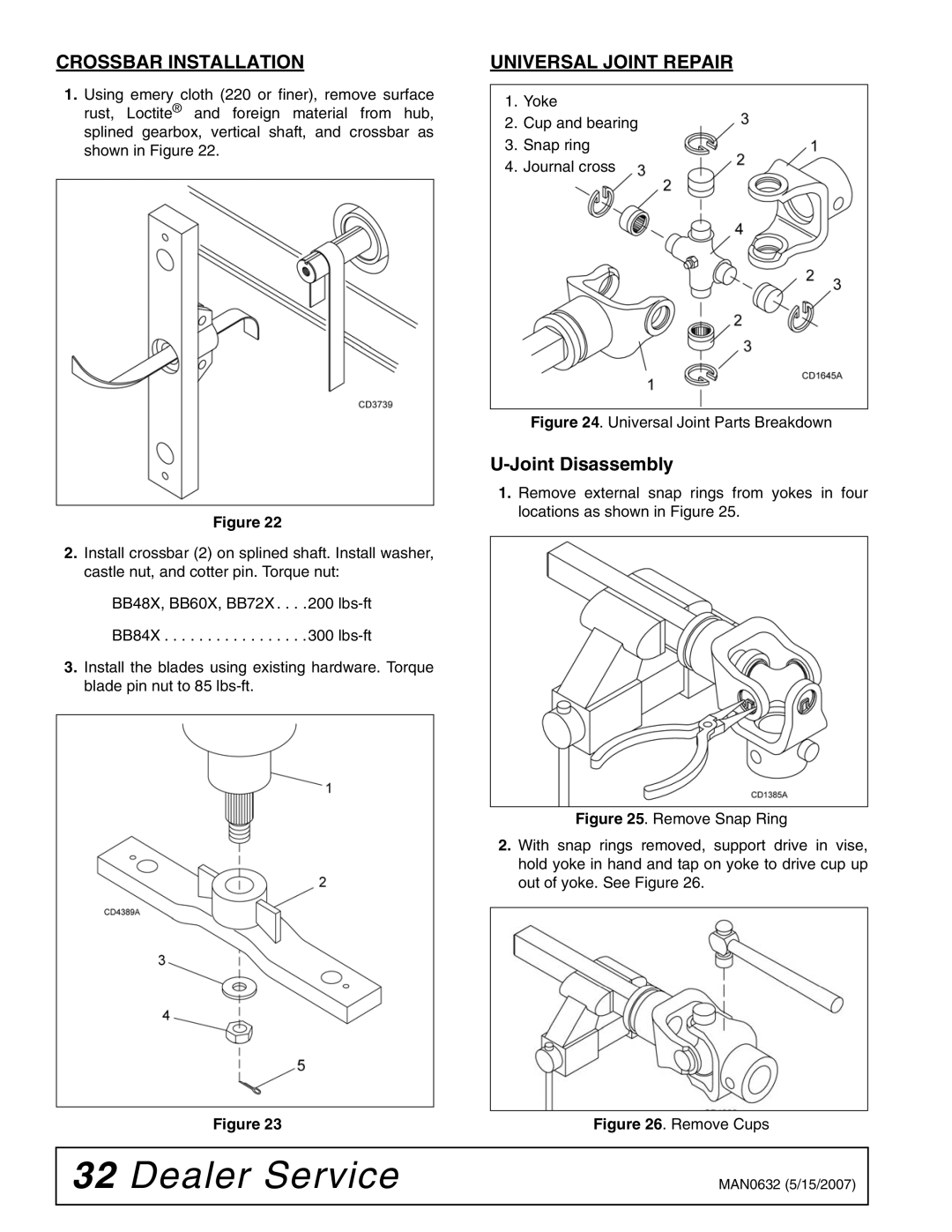

Universal Joint Repair

Crossbar Installation

Joint Disassembly

Joint Assembly

Install Cups

Dealer Check Lists

Dealer Check Lists

PRE-DELIVERY Check List

Delivery Check List

Dealer Check Lists

Dealer SET-UP Instructions

Assembly

Assembly

BB60X, BB72X & BB84X Shipping Configuration

Disassemble Shipping Unit Figure

Install A-FRAME

Install A-FRAME to Diagonal Brace Bars

BB48X

BB60X, BB72X & BB84X

Install Tailwheel

Install Dual Tailwheel BB84XD Optional

BB48X Standard Hitch Set-Up

BB48X Quick Hitch Set-Up

Install Driveline

BB60X, BB72X & BB84X Standard & Quick Hitch Set-Up

Shear Bolt Driveline BB48X & BB60X Only

Driveline Slip Clutch Optional on BB48X & BB60X

Install Safety Shielding

Driveline Slip Clutch BB72X and BB84X

Rubber Deflector Standard

Fill Gearbox

BB84X

Install Optional Check Chains

BB60X BB72X

Parts Index Brushbulltm

Parts

Brushbull STANDARD-DUTY Main Assembly

BB48X, BB60X, BB72X & BB84X BB84X Shown

BB48X, BB60X, BB72X & BB84X Main Assembly Parts List

BB72X, BB84X

Gearbox Assembly Flat TOP

Gearbox repair asy BB72X S/N 1159928 and Below

BB48X

Gearbox Assembly Parts List

Check Chain Assembly Optional

Gearbox Assembly CAST/CROWN TOP

BB48X Comer Standard Driveline Assembly

BB60X Comer Standard Driveline Assembly

BB48X & BB60X Comer Slip Clutch Driveline Assembly Optional

BB72X Comer Slip Clutch Driveline Assembly

BB84X Comer Slip Clutch Driveline Assembly

Series 50 Series

BB84X Walterscheid Slip Clutch Driveline Assembly

Front & Rear Chain Shielding Optional

Front Rubber Shielding Standard

Bolt Torque Chart

SAE Series Torque Chart

Appendix

Metric Series

Bolt Size Chart

Abbreviations

Index

Index

Warranty

Rev /23/2005