RBC60 LRC60 specifications

Woods Equipment Company is renowned for its commitment to high-quality agricultural and landscaping machinery. One of their standout products is the RBC60 LRC60 landscape rake, specifically designed for commercial users and serious landscapers looking for reliability and efficiency in their projects.The Woods RBC60 LRC60 features a robust design, emphasizing durability without sacrificing performance. Its construction incorporates heavy-duty materials, ensuring prolonged use even in demanding conditions. This model has been engineered to withstand the rigors of regular use on various terrains, making it an ideal choice for both commercial and residential landscaping tasks.

One of the main features of the RBC60 LRC60 is its adjustable rake angle. Users can quickly adapt the rake's position to suit different applications, from leveling soil to spreading gravel or mulch efficiently. This adjustability allows operators to achieve optimal results, tailoring their approach to the specific requirements of each job.

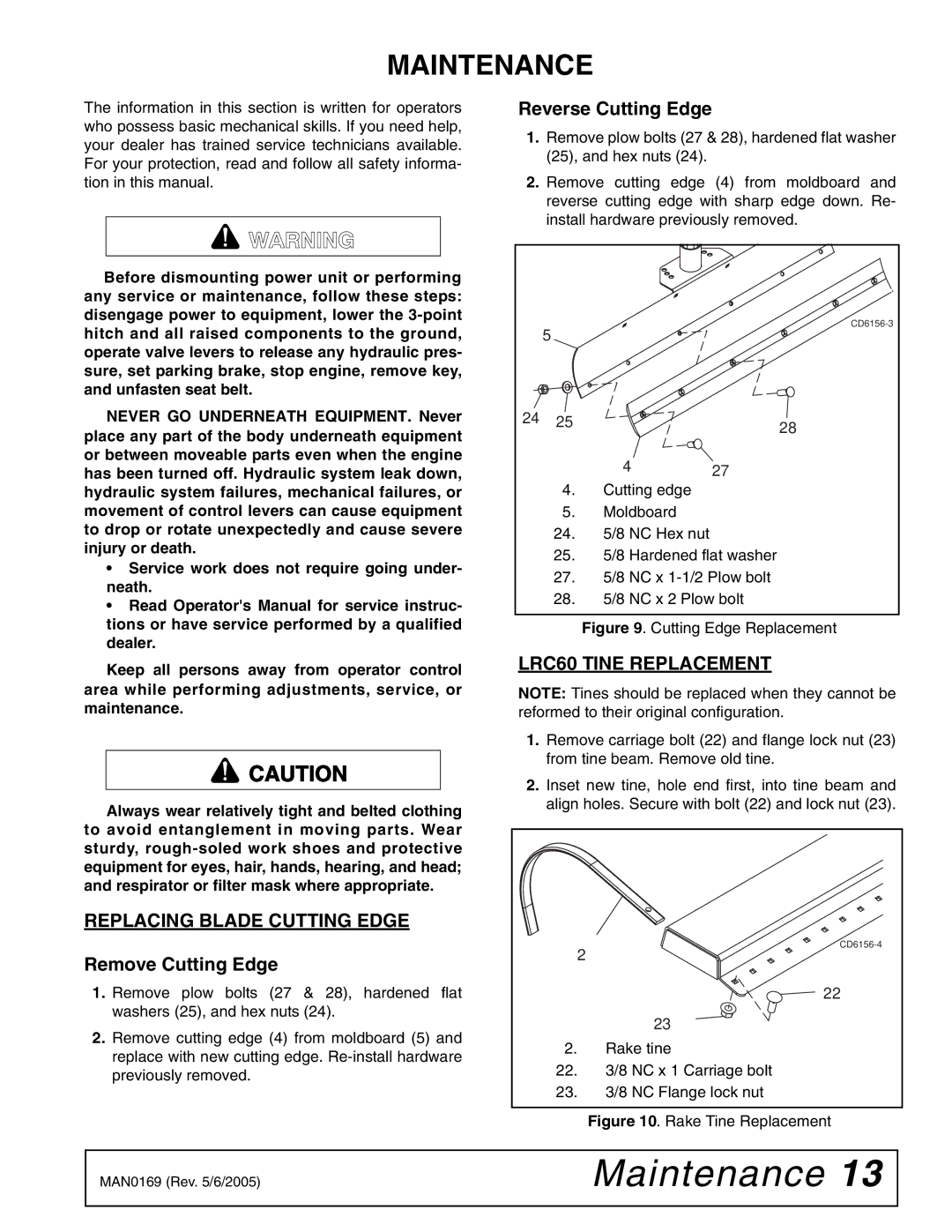

Additionally, the RBC60 LRC60 comes equipped with a unique set of tines. These tines are designed for versatility, allowing for effective soil preparation, debris collection, and fine grading. The design ensures that elements like rocks and other unwanted materials are efficiently disturbed, making it easier for landscapers to achieve a smooth, even surface.

The hydraulic lift system provides ease of operation, allowing users to raise and lower the rake effortlessly while maintaining control. This feature helps maximize productivity, as operators can quickly transition between tasks without needing to leave their machinery.

Another essential characteristic of the Woods RBC60 LRC60 is its compatibility with a wide range of tractors. This versatility allows it to be used in various applications, from landscaping and gardening to preparing fields. The attachment system is designed for quick disconnect, making it user-friendly for those who operate multiple tools in their work.

In summary, the Woods Equipment RBC60 LRC60 landscape rake combines durability, versatility, and efficiency. Its adjustable rake angle, specialized tines, and hydraulic lift system provide landscapers with the tools they need to tackle a variety of projects effectively. As such, the RBC60 LRC60 represents a valuable addition to the arsenal of any serious professional in the landscaping and agricultural sector, ensuring outstanding performance and reliability on every job.