ASSEMBLY

Back Stop

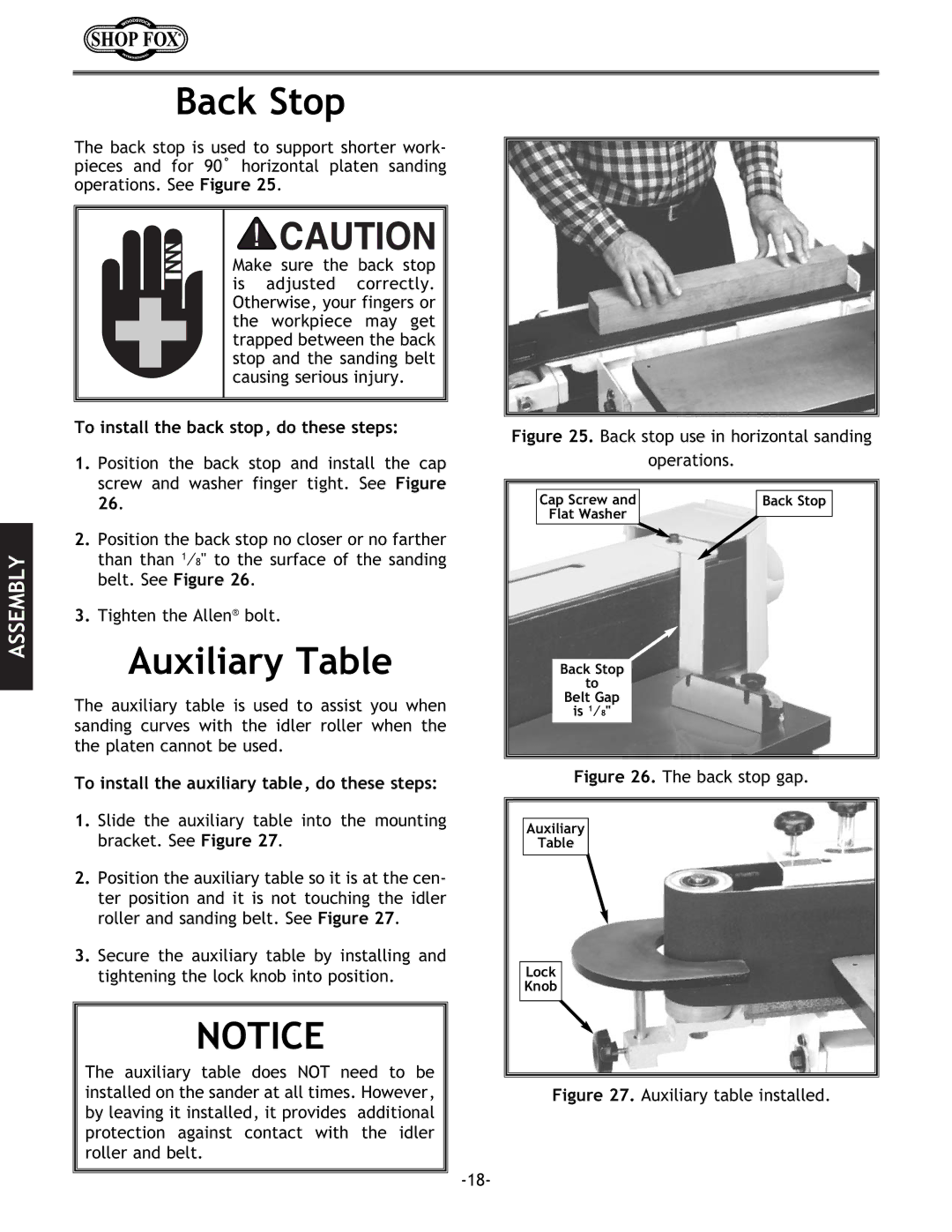

The back stop is used to support shorter work- pieces and for 90˚ horizontal platen sanding operations. See Figure 25.

Make sure the back stop is adjusted correctly. Otherwise, your fingers or the workpiece may get trapped between the back stop and the sanding belt causing serious injury.

To install the back stop, do these steps:

1.Position the back stop and install the cap screw and washer finger tight. See Figure 26.

2.Position the back stop no closer or no farther than than 1⁄8" to the surface of the sanding belt. See Figure 26.

3.Tighten the Allen® bolt.

Auxiliary Table

The auxiliary table is used to assist you when sanding curves with the idler roller when the the platen cannot be used.

To install the auxiliary table, do these steps:

1.Slide the auxiliary table into the mounting bracket. See Figure 27.

2.Position the auxiliary table so it is at the cen- ter position and it is not touching the idler roller and sanding belt. See Figure 27.

3.Secure the auxiliary table by installing and tightening the lock knob into position.

NOTICE

The auxiliary table does NOT need to be installed on the sander at all times. However, by leaving it installed, it provides additional protection against contact with the idler roller and belt.

Figure 25. Back stop use in horizontal sanding

operations.

Cap Screw and | Back Stop |

Flat Washer |

|

Back Stop |

|

to |

|

Belt Gap |

|

is 1⁄8" |

|

Figure 26. The back stop gap.

Auxiliary

Table

Lock

Knob