Platen Mount

Hex Bolts

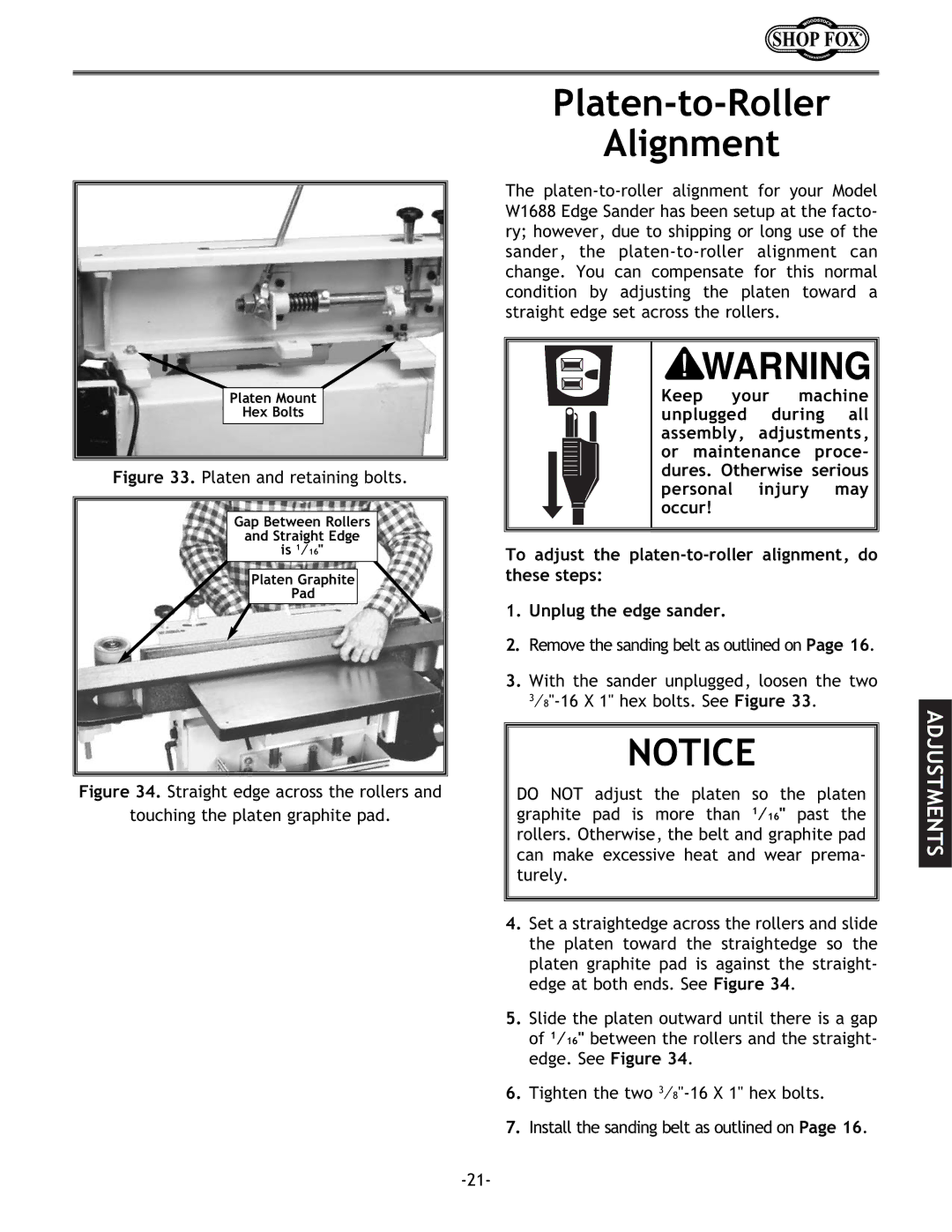

Figure 33. Platen and retaining bolts.

Gap Between Rollers |

and Straight Edge |

is 1⁄16" |

Platen Graphite |

Pad |

Figure 34. Straight edge across the rollers and

touching the platen graphite pad.

Platen-to-Roller

Alignment

The

Keep your machine unplugged during all assembly, adjustments, or maintenance proce- dures. Otherwise serious personal injury may occur!

To adjust the

1.Unplug the edge sander.

2.Remove the sanding belt as outlined on Page 16.

3.With the sander unplugged, loosen the two

NOTICE

DO NOT adjust the platen so the platen graphite pad is more than 1⁄16" past the rollers. Otherwise, the belt and graphite pad can make excessive heat and wear prema- turely.

4.Set a straightedge across the rollers and slide the platen toward the straightedge so the platen graphite pad is against the straight- edge at both ends. See Figure 34.

5.Slide the platen outward until there is a gap of 1⁄16" between the rollers and the straight- edge. See Figure 34.

6.Tighten the two

7.Install the sanding belt as outlined on Page 16.

ADJUSTMENTS