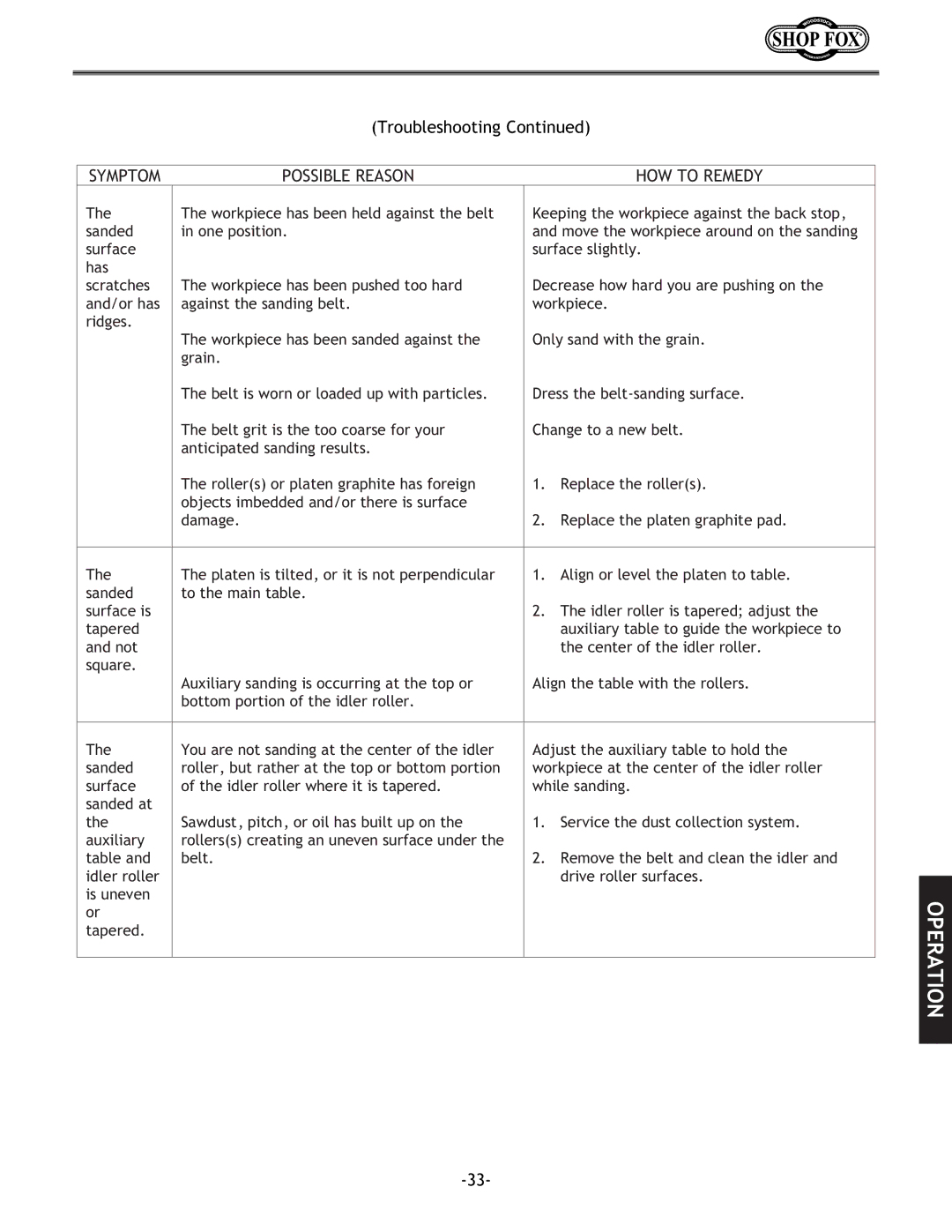

(Troubleshooting Continued)

SYMPTOM | POSSIBLE REASON |

| HOW TO REMEDY |

The | The workpiece has been held against the belt | Keeping the workpiece against the back stop, | |

sanded | in one position. | and move the workpiece around on the sanding | |

surface |

| surface slightly. | |

has |

|

|

|

scratches | The workpiece has been pushed too hard | Decrease how hard you are pushing on the | |

and/or has | against the sanding belt. | workpiece. | |

ridges. | The workpiece has been sanded against the | Only sand with the grain. | |

| |||

| grain. |

|

|

| The belt is worn or loaded up with particles. | Dress the | |

| The belt grit is the too coarse for your | Change to a new belt. | |

| anticipated sanding results. |

|

|

| The roller(s) or platen graphite has foreign | 1. | Replace the roller(s). |

| objects imbedded and/or there is surface |

|

|

| damage. | 2. Replace the platen graphite pad. | |

|

|

|

|

The | The platen is tilted, or it is not perpendicular | 1. | Align or level the platen to table. |

sanded | to the main table. |

|

|

surface is |

| 2. The idler roller is tapered; adjust the | |

tapered |

|

| auxiliary table to guide the workpiece to |

and not |

|

| the center of the idler roller. |

square. |

|

|

|

| Auxiliary sanding is occurring at the top or | Align the table with the rollers. | |

| bottom portion of the idler roller. |

|

|

|

|

| |

The | You are not sanding at the center of the idler | Adjust the auxiliary table to hold the | |

sanded | roller, but rather at the top or bottom portion | workpiece at the center of the idler roller | |

surface | of the idler roller where it is tapered. | while sanding. | |

sanded at |

|

|

|

the | Sawdust, pitch, or oil has built up on the | 1. | Service the dust collection system. |

auxiliary | rollers(s) creating an uneven surface under the |

|

|

table and | belt. | 2. Remove the belt and clean the idler and | |

idler roller |

|

| drive roller surfaces. |

is uneven |

|

|

|

or |

|

|

|

tapered. |

|

|

|

|

|

|

|