W1752 Owner's Manual (Mfg. 1/07+)

Faceplate Turning

Faceplate turning (Figure 22) is when a workpiece is mounted to the 3" faceplate, which is mounted to the headstock spindle. This type of turning is usually done with

To mount your workpiece to the faceplate, do these steps:

1.Find the center of your workpiece in the same man- ner as when spindle turning.

2.Cut off the corners of the workpiece.

3.Center the faceplate on the workpiece and attach it through the faceplate holes with wood screws.

4.Thread the faceplate onto the headstock spindle and tighten securely.

Note: If screws cannot be placed in the workpiece, then a backing block can be glued to the workpiece and attached to the faceplate with screws.

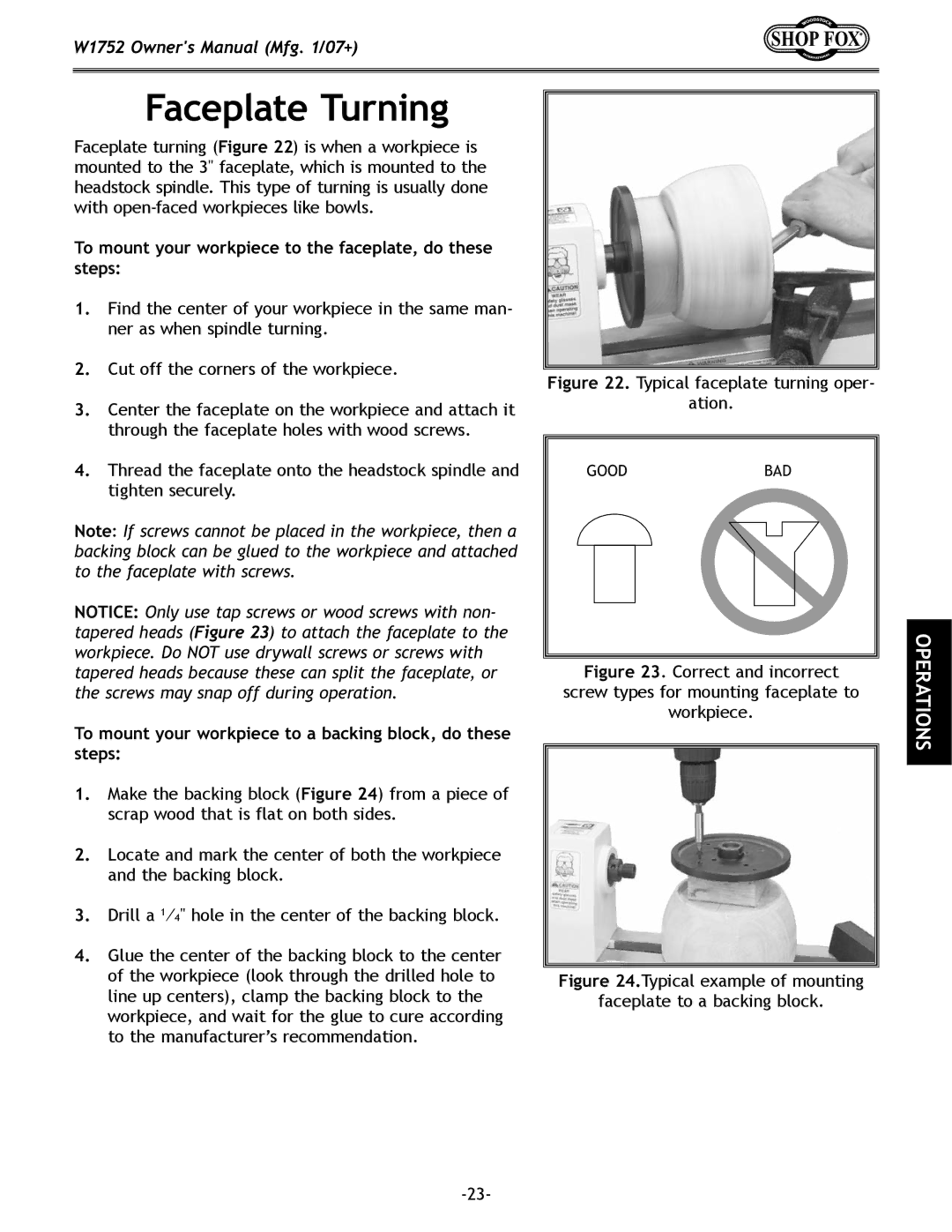

NOTICE: Only use tap screws or wood screws with non- tapered heads (Figure 23) to attach the faceplate to the workpiece. Do NOT use drywall screws or screws with tapered heads because these can split the faceplate, or the screws may snap off during operation.

To mount your workpiece to a backing block, do these steps:

1.Make the backing block (Figure 24) from a piece of scrap wood that is flat on both sides.

2.Locate and mark the center of both the workpiece and the backing block.

3.Drill a 1⁄4" hole in the center of the backing block.

4.Glue the center of the backing block to the center of the workpiece (look through the drilled hole to line up centers), clamp the backing block to the workpiece, and wait for the glue to cure according to the manufacturer’s recommendation.

Figure 22. Typical faceplate turning oper-

ation.

GOODBAD

Figure 23. Correct and incorrect

screw types for mounting faceplate to

workpiece.

Figure 24.Typical example of mounting

faceplate to a backing block.

OPERATIONS