When fastening ductwork to side duct flanges on unit, insert screws through duct flanges only. DO NOT insert screws through casing. Outdoor duct- work must be insulated and

FIGURE 13 - SIDE PANELS WITH HOLE PLUGS

Note orientation. Panel is “insulation” side up.

CONDENSATE DRAIN

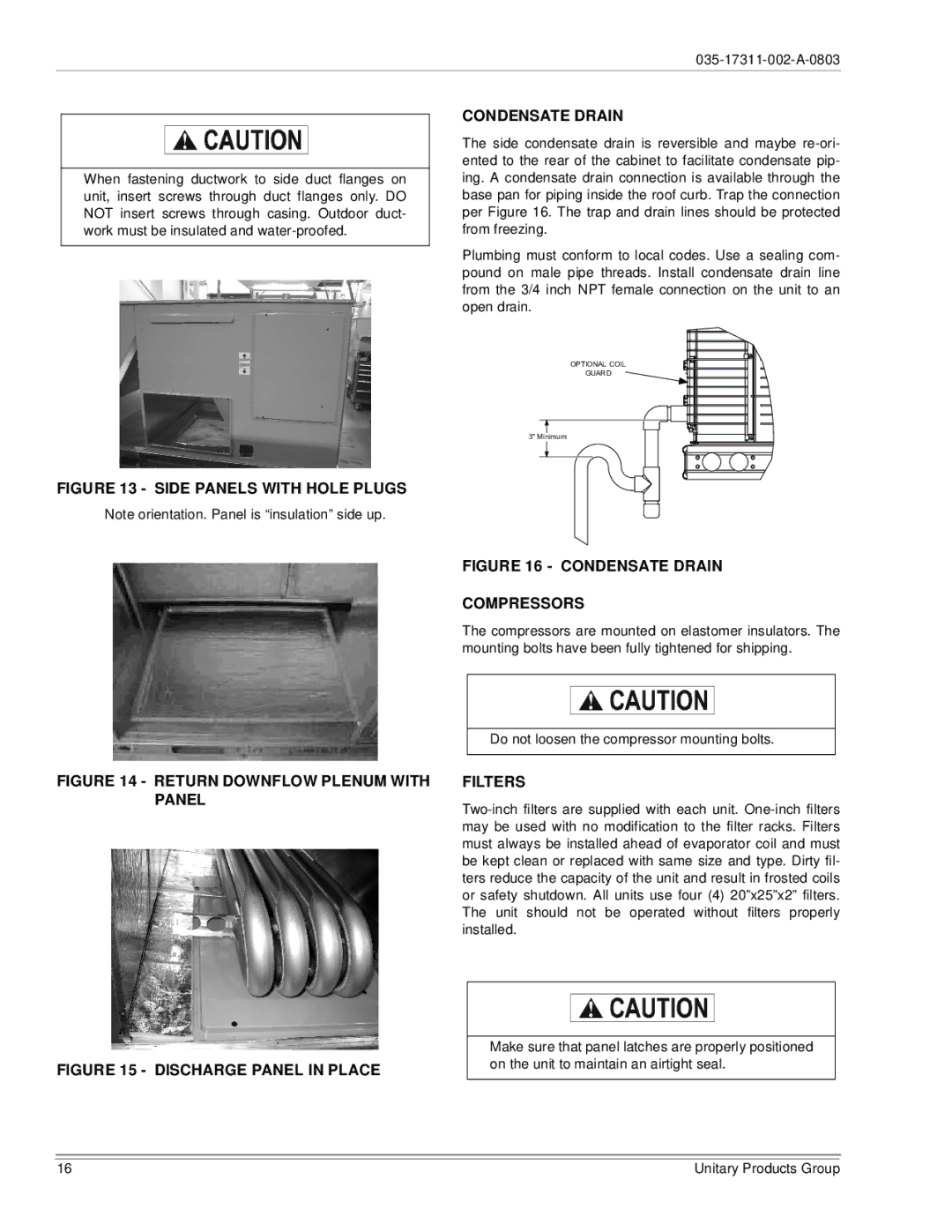

The side condensate drain is reversible and maybe

Plumbing must conform to local codes. Use a sealing com- pound on male pipe threads. Install condensate drain line from the 3/4 inch NPT female connection on the unit to an open drain.

OPTIONALCOIL

GUARD

3"Minimum

FIGURE 16 - CONDENSATE DRAIN

COMPRESSORS

The compressors are mounted on elastomer insulators. The mounting bolts have been fully tightened for shipping.

Do not loosen the compressor mounting bolts.

FIGURE 14 - RETURN DOWNFLOW PLENUM WITH FILTERS

PANEL

FIGURE 15 - DISCHARGE PANEL IN PLACE

Make sure that panel latches are properly positioned on the unit to maintain an airtight seal.

16 | Unitary Products Group |