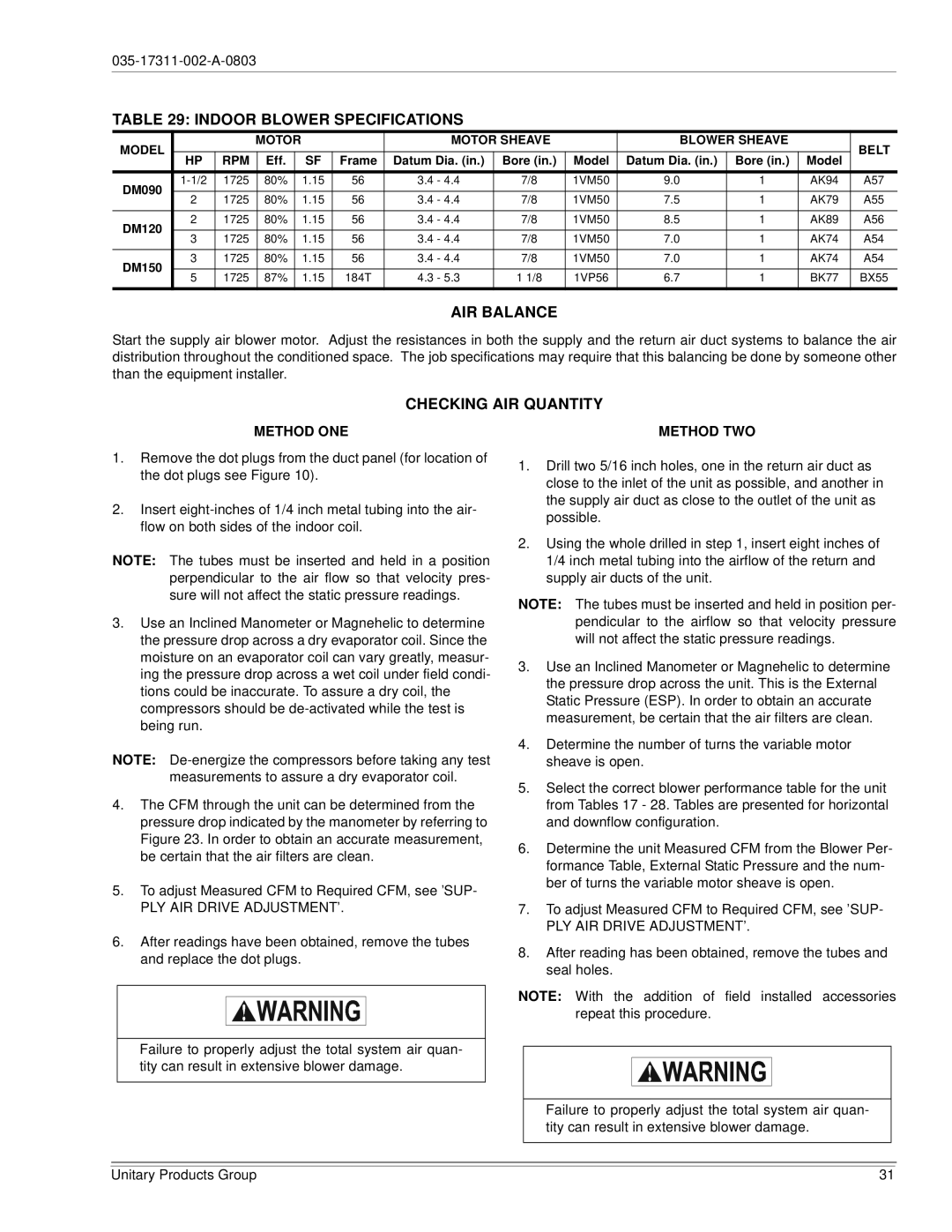

TABLE 29: INDOOR BLOWER SPECIFICATIONS

MODEL |

|

| MOTOR |

|

| MOTOR SHEAVE |

| BLOWER SHEAVE |

| BELT | |||

|

|

|

|

|

|

|

|

|

|

|

| ||

| HP | RPM | Eff. |

| SF | Frame | Datum Dia. (in.) | Bore (in.) | Model | Datum Dia. (in.) | Bore (in.) | Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

DM090 | 1725 | 80% | 1.15 | 56 | 3.4 - 4.4 | 7/8 | 1VM50 | 9.0 | 1 | AK94 | A57 | ||

|

|

|

|

|

|

|

|

|

|

|

|

| |

2 | 1725 | 80% |

| 1.15 | 56 | 3.4 - 4.4 | 7/8 | 1VM50 | 7.5 | 1 | AK79 | A55 | |

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DM120 | 2 | 1725 | 80% |

| 1.15 | 56 | 3.4 - 4.4 | 7/8 | 1VM50 | 8.5 | 1 | AK89 | A56 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

3 | 1725 | 80% |

| 1.15 | 56 | 3.4 - 4.4 | 7/8 | 1VM50 | 7.0 | 1 | AK74 | A54 | |

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DM150 | 3 | 1725 | 80% |

| 1.15 | 56 | 3.4 - 4.4 | 7/8 | 1VM50 | 7.0 | 1 | AK74 | A54 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

5 | 1725 | 87% |

| 1.15 | 184T | 4.3 - 5.3 | 1 1/8 | 1VP56 | 6.7 | 1 | BK77 | BX55 | |

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AIR BALANCE

Start the supply air blower motor. Adjust the resistances in both the supply and the return air duct systems to balance the air distribution throughout the conditioned space. The job specifications may require that this balancing be done by someone other than the equipment installer.

CHECKING AIR QUANTITY

METHOD ONE | METHOD TWO |

1.Remove the dot plugs from the duct panel (for location of the dot plugs see Figure 10).

2.Insert

NOTE: The tubes must be inserted and held in a position perpendicular to the air flow so that velocity pres- sure will not affect the static pressure readings.

3.Use an Inclined Manometer or Magnehelic to determine the pressure drop across a dry evaporator coil. Since the moisture on an evaporator coil can vary greatly, measur- ing the pressure drop across a wet coil under field condi- tions could be inaccurate. To assure a dry coil, the compressors should be

NOTE:

4.The CFM through the unit can be determined from the pressure drop indicated by the manometer by referring to Figure 23. In order to obtain an accurate measurement, be certain that the air filters are clean.

5.To adjust Measured CFM to Required CFM, see ’SUP-

PLY AIR DRIVE ADJUSTMENT’.

6.After readings have been obtained, remove the tubes and replace the dot plugs.

Failure to properly adjust the total system air quan- tity can result in extensive blower damage.

1.Drill two 5/16 inch holes, one in the return air duct as close to the inlet of the unit as possible, and another in the supply air duct as close to the outlet of the unit as possible.

2.Using the whole drilled in step 1, insert eight inches of 1/4 inch metal tubing into the airflow of the return and supply air ducts of the unit.

NOTE: The tubes must be inserted and held in position per- pendicular to the airflow so that velocity pressure will not affect the static pressure readings.

3.Use an Inclined Manometer or Magnehelic to determine the pressure drop across the unit. This is the External Static Pressure (ESP). In order to obtain an accurate measurement, be certain that the air filters are clean.

4.Determine the number of turns the variable motor sheave is open.

5.Select the correct blower performance table for the unit from Tables 17 - 28. Tables are presented for horizontal and downflow configuration.

6.Determine the unit Measured CFM from the Blower Per- formance Table, External Static Pressure and the num- ber of turns the variable motor sheave is open.

7.To adjust Measured CFM to Required CFM, see ’SUP-

PLY AIR DRIVE ADJUSTMENT’.

8.After reading has been obtained, remove the tubes and seal holes.

NOTE: With the addition of field installed accessories repeat this procedure.

Failure to properly adjust the total system air quan- tity can result in extensive blower damage.

Unitary Products Group | 31 |