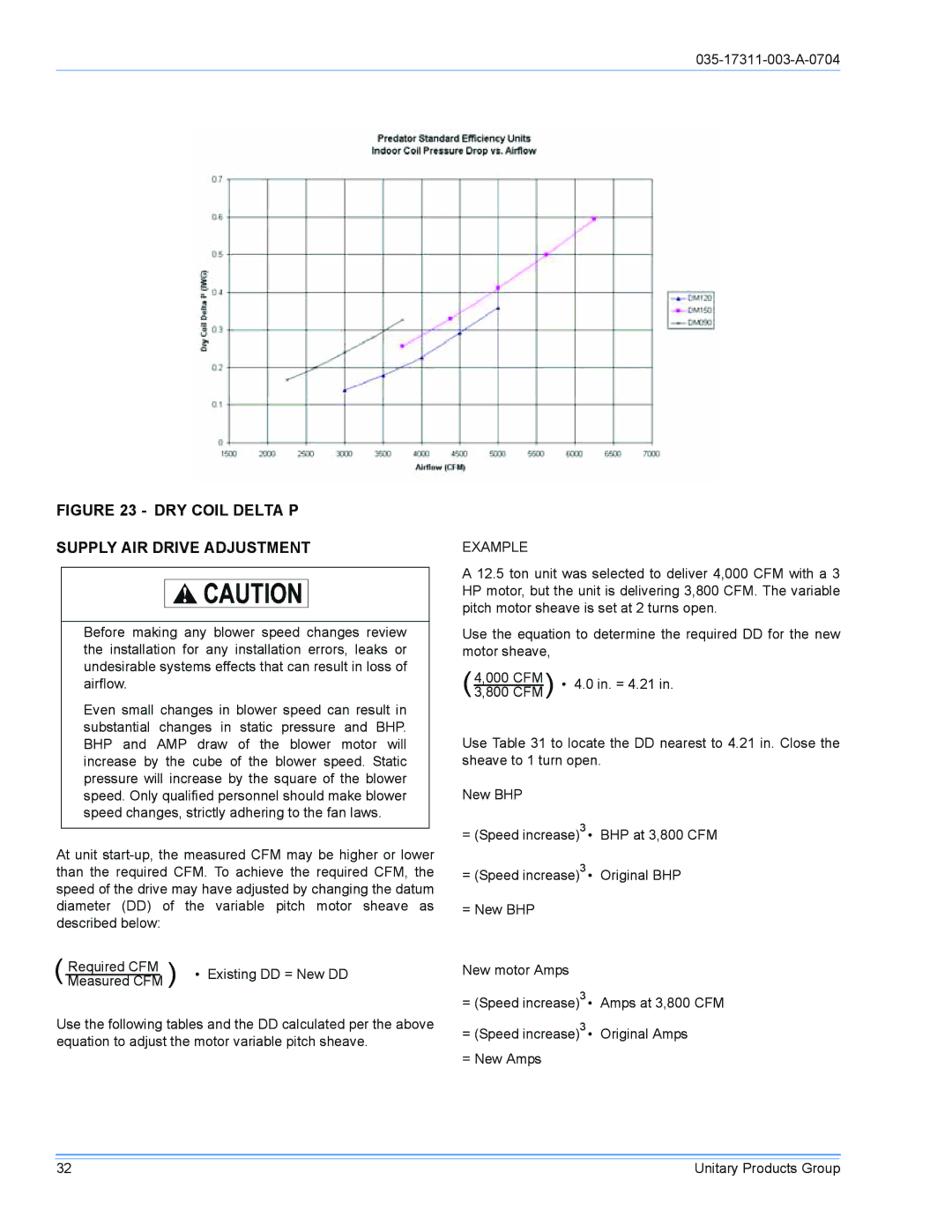

FIGURE 23 - DRY COIL DELTA P

SUPPLY AIR DRIVE ADJUSTMENT

Before making any blower speed changes review the installation for any installation errors, leaks or undesirable systems effects that can result in loss of airflow.

Even small changes in blower speed can result in substantial changes in static pressure and BHP. BHP and AMP draw of the blower motor will increase by the cube of the blower speed. Static pressure will increase by the square of the blower speed. Only qualified personnel should make blower speed changes, strictly adhering to the fan laws.

At unit

( | Required CFM |

Measured CFM ) • Existing DD = New DD |

Use the following tables and the DD calculated per the above equation to adjust the motor variable pitch sheave.

EXAMPLE

A 12.5 ton unit was selected to deliver 4,000 CFM with a 3 HP motor, but the unit is delivering 3,800 CFM. The variable pitch motor sheave is set at 2 turns open.

Use the equation to determine the required DD for the new motor sheave,

(4,0003,800 CFMCFM ) • 4.0 in. = 4.21 in.

Use Table 31 to locate the DD nearest to 4.21 in. Close the sheave to 1 turn open.

New BHP

=(Speed increase)3 • BHP at 3,800 CFM

=(Speed increase)3 • Original BHP

=New BHP

New motor Amps

=(Speed increase)3 • Amps at 3,800 CFM

=(Speed increase)3 • Original Amps

=New Amps

32 | Unitary Products Group |