Form 201.23-EG1

Table of Contents

York Yciv Air Cooled Screw Liquid Chillers

Introduction

Refrigerant Circuit

Specifications

Power and Electrical

M I H E R M E T I C Y O R K T W I N S C R E W Compressors

Microprocessor Controls

Evaporator

Condenser Section

Complete Factory Package

Protective Chiller Panels

Accessories and Options

MULTI-UNIT Sequence Control

Pressure Relief CE/PED Service Valve KIT

Evaporator Options

Building Automation System Interface

Nomenclature

Johnson Controls

Temperatures and Flows

0770S/P 0207S/P

0600S/P 0157S/P

0650S/P 0177S/P

0720S/P 0187S/P

Cooler Model number Yciv 60Hz 50Hz

Water Pressure Drop

SI Units

1340S/P

Evap Yciv Models

1070S/P

1180S/P

SI Units

Model YCIV0187S/P

Standard Efficiency Ratings English 460V/60Hz

Model YCIV0157S/P

Model YCIV0177S/P

Model YCIV0247S/P

Model YCIV0207S/P

Model YCIV0227S/P

Model YCIV0307S/P

Model YCIV0267S/P

Model YCIV0287S/P

Model YCIV0157E/V

Model YCIV0357S/P

Model YCIV0397S/P

Model YCIV0197E/V

High Efficiency Ratings English 460V/60Hz

Model YCIV0177E/V

Model YCIV0187E/V

Eiplv = 12.8 Viplv =

Model YCIV0207E/V

Model YCIV0227E/V

Model YCIV0247E/V

75.0 80.0

Model YCIV0267E/V

Model YCIV0287E/V

Model YCIV0327E/V

Model YCIV0357E/V

MODELYCIV0177S/P

AIR Temperature on Condenser C Lcwt

Standard Efficiency Ratings SI 460V/60Hz

MODELYCIV0157S/P

MODELYCIV0247S/P

MODELYCIV0207S/P

MODELYCIV0227S/P

25.0 30.0 35.0 40.0 45.0 46.0

MODELYCIV0267S/P

MODELYCIV0287S/P

MODELYCIV0307S/P

MODELYCIV0397S/P

MODELYCIV0357S/P

MODELYCIV0187E/V

High Efficiency Ratings SI 460V/60Hz

MODELYCIV0157E/V

MODELYCIV0177E/V

MODELYCIV0227E/V

MODELYCIV0197E/V

MODELYCIV0207E/V

MODELYCIV0287E/V

MODELYCIV0247E/V

MODELYCIV0267E/V

MODELYCIV0357E/V

MODELYCIV0327E/V

Model YCIV0720S/P

Standard Efficiency Ratings SI 400V/50Hz

Model YCIV0600S/P

Model YCIV0650S/P

25.0 30.0 35.0 40.0 45.0 46.0 KWi

Model YCIV0770S/P

Model YCIV0840S/P

Model YCIV0920S/P

Model YCIV1180S/P

Model YCIV1000S/P

Model YCIV1070S/P

Model YCIV1500S/P

Model YCIV1340S/P

Model YCIV0700E/V

High Efficiency Ratings SI 400V/50Hz

Model YCIV0590E/V

Model YCIV0630E/V

Model YCIV0830E/V

Model YCIV0760E/V

Model YCIV0800E/V

Model YCIV1120E/V

Model YCIV0930E/V

Model YCIV1050E/V

Model YCIV1380E/V

Model YCIV1220E/V

10.3

Standard Efficiency Ratings English 380V/60Hz

10.0

15.1

13.6 265.9

13.0 250.2

13.3 258.0

12.4 255.6

10.4 322.9

13.1 333.4

12.1 330.1

11.2 326.6

15.7

High Efficiency Ratings English 380V/60Hz

15.6

75.0

11.7 297.2

305.7

13.7 303.0

12.7 300.2

Standard Efficiency Ratings SI 380V/60Hz

Model YCIV0207S/P

Model YCIV307S/P

Model YCIV267S/P

Model YCIV287S/P

Model YCIV397S/P

Model YCIV357S/P

High Efficiency Ratings SI 380V/60Hz

Model YCIV0197E/V

Model YCIV0247E/V

25.0 30.0 35.0 40.0 45.0 46.0 KWi

Standard Efficiency

Physical Data English Standard Efficiency

Comp.s, Semihermetic Screw

General Unit Data 60Hz 0287 0307 0357 0397 50Hz 1070

0930

Physical Data English High Efficiency

High Efficiency

0800

1220

General Unit Data 60Hz 0267

0327 0357 50Hz

1000

Physical Data SI Standard Efficiency

0770 0840

Compressors, Semihermetic Screw

Physical Data SI High Efficiency

98176

General Unit Data 60Hz 0267

0327 0357 50Hz 1550

1380

29.1

Dimensions English

Models YCIV0157E/V and YCIV0157S/P

28.1

View D-D

80.0 230.0

Dimensions English

Yciv

88.1 274.0

Mounting Holes TYP Control Panel

22.2 26.0 79.1

Models YCIV0197E/V, YCIV0207S/P, and YCIV0227S/P

20.4 28.1 85.6 112.3

22.2 26.0 79.1 113.3

274

88 1/8

Models YCIV0207E/V and YCIV0227E/V

20 3/8 28 1/8 Edge of Unit

Mounting Holes TYP

22 3/16

Models YCIV0247S/P, YCIV0247E/V, and YCIV0267S/P

Wide X 13 1/2 High

Mounting Holes TYP APPROX. Operating Weight Distributing LB

Models YCIV0267E/V, and YCIV0287S/P

Mounting Holes TYP Control Panel

Models YCIV0287E/V

Mounting Holes TYP

Models YCIV0307S/P

Water Outlet Water Inlet Rigging Holes

Models YCIV0327E/V and YCIV0357S/P

Control Panel Origin

Models YCIV0357E/V and YCIV0397S/P

View D-D Origin

442

Dimensions SI

YCIV0590E/V and YCIV0600S/P

485

Water Outlet Rigging Holes

2032

Dimensions SI

YCIV0630E/V, YCIV0650S/P, YCIV0700E/V and YCIV0720S/P

2238

Dimensions mm Unless Otherwise Noted

564

YCIV0760E/V, YCIV0770S/P, and YCIV0890S/P

518

Mounting Holes TYP Origin Panel

518

YCIV0800E/V and YCIV0830E/V

Water Outlet Mounting Holes TYP

564

YCIV0920S/P, YCIV0930E/V, and YCIV1000S/P

Rigging Holes Water Outlet Each Side 76 X

View A-A 305

YCIV1050E/V and YCIV1070S/P

Rigging Holes Water Outlet Water Inlet Each Side 76 X

YCIV1120E/V

Power Single Point with Terminal Block Origin Panel

YCIV1180S/P

Water Outlet Water Inlet Each Side 76 X

YCIV1220E/V and YCIV1340S/P

101

YCIV1380E/V and YCIV1500S/P

103

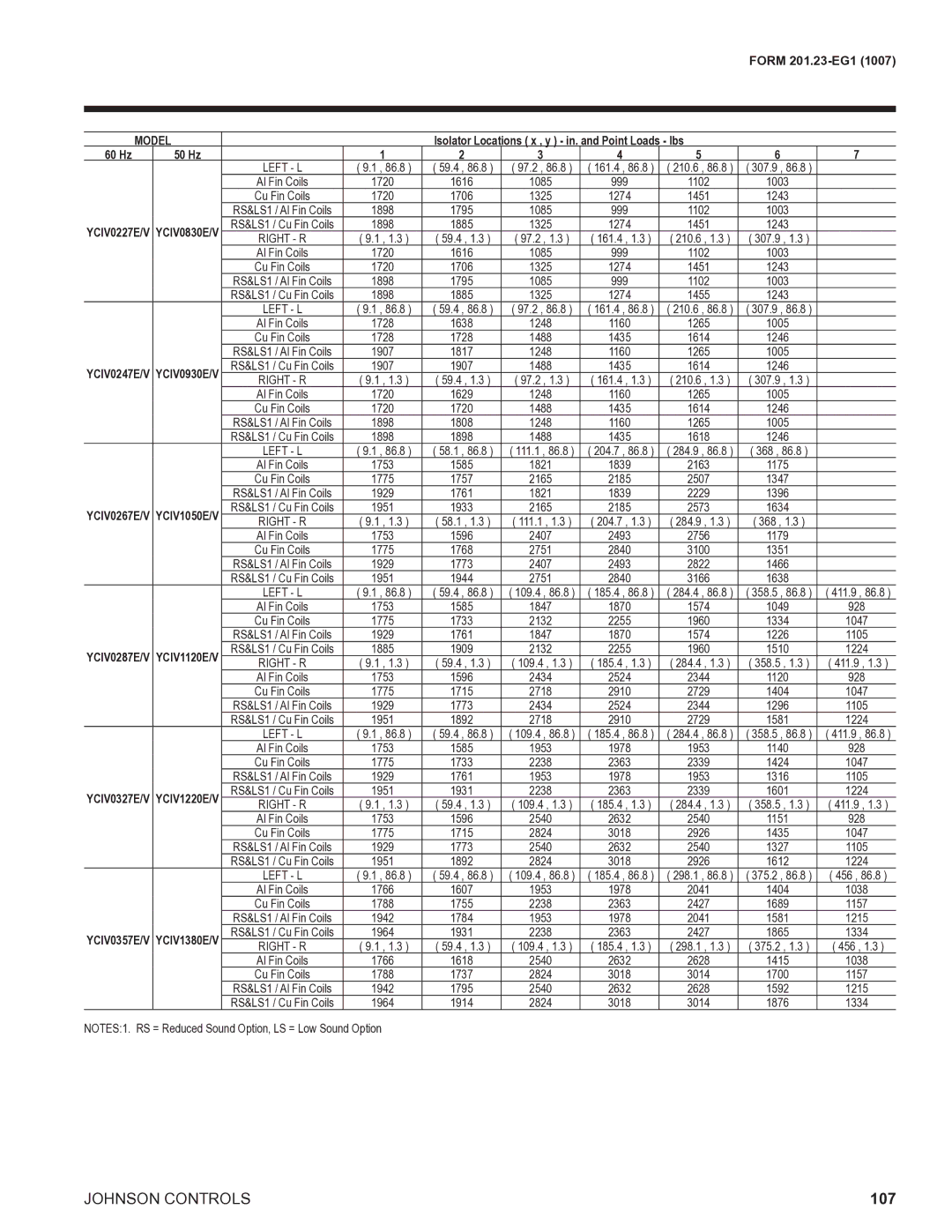

Isolator Locations x , y in. and Point Loads lbs

Isolator Locations English

Model

2156

1753

1810

1775

High Efficiency English Model

Isolator Locations English

2493

1274

1839

2185

Isolator Locations x , y mm and Point Loads kg

Isolator Locations SI

Standard Efficiency SI Model

730

566

572

675

High Efficiency SI Model

658

492

500

601

For Units with ANY Point Load Above 1404 LBS 637 KG

Isolator Details

ONE Inch Deflection Spring Isolator CROSS-REFERENCE

For Units with ALL Point Loads Less Thatn 1404 LBS 637 KG

ND-DS

Neoprene Isolator CROSS-REFERENCE

English MBD ND-C

ND-D

Size HCL HCW MBD

Isolator Details contd

English Size HCL HCW MBD

Intentionally Left Blank

OPT

Electrical Data 2 Comp Standard Efficiency

Yciv S/P

Two-Speed Cond. Fans

Yciv S/P

Yciv E/V

Electrical Data 2 Comp High Efficiency

High Head/High Static Fans Two-Speed Cond. Fans

Form 201.23-EG1 High Efficiency Yciv E/V

FLA EA

Electrical Data 3 Comp Standard Efficiency

STD Terminal Block OPT Circuit Breaker

Field Wiring Lugs

Form 201.23-EG1 System

High Head/High Static Fans

Unit Short Circuit Field Wiring & Protection

Electrical Data 3 Comp High Efficiency

Withstand KA

Fuse/Ckt

Lugs/ Phase

Electrical Notes

Two COMPressor Wiring Diagram with Circuit Breaker

Power Wiring

126

127

Typical Control Wiring Two Compressor

129

Typical Control Wiring Three Compressor

131

Chilled Liquid Piping

Application Data

Unit Location

Foundation

Delivery and Handling

Guide Specifications

Part 1 General

Quality Assurance

Refrigerant Circuit Components

Compressors and Motors

Controls

Power and Electrical Requirements

PRE-COATED FIN Condenser Coils

Accessories and Options

Part 3 Execution Installation

138

139

Form 201.23-EG1 Supersedes 201.23-EG1 File in ET2