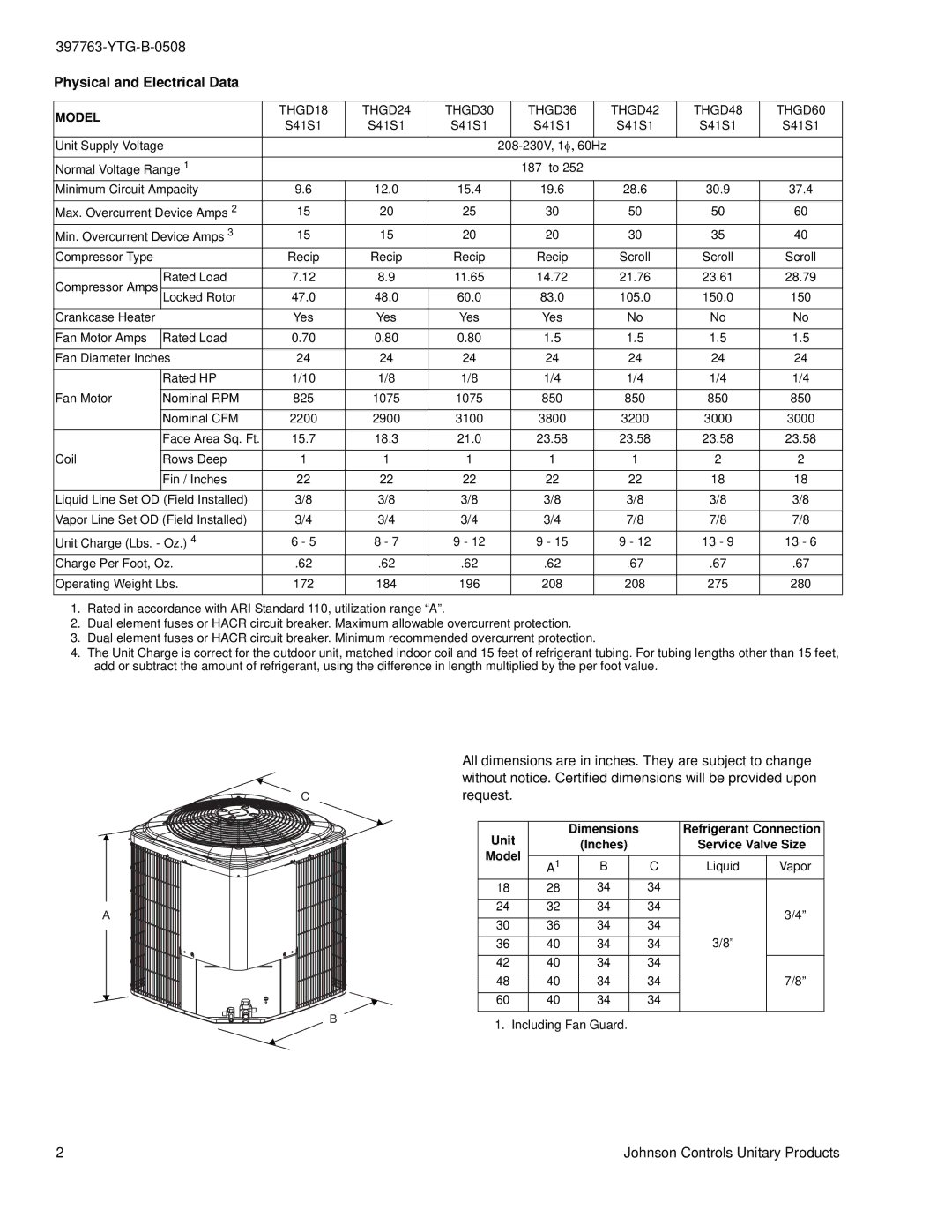

THGD18 THRU 60 specifications

The York THGD18 THRU 60 is a prominent addition to the realm of commercial air conditioning systems, designed specifically to provide high efficiency and reliability in various environments. This series offers a range from 18 to 60 tons, making it suitable for diverse applications, including restaurants, retail spaces, and office buildings.One of the standout features of the York THGD18 THRU 60 is its Variable Speed Technology. This innovative approach allows the system to adjust its cooling performance in response to the surrounding conditions. By optimizing compressor speed, it maintains consistent temperatures while significantly reducing energy consumption. This not only leads to lower utility bills but also minimizes the carbon footprint, making it an ideal choice for environmentally conscious users.

In terms of durability, the THGD series is constructed with robust materials designed to withstand harsh weather conditions. This durability is complemented by the unit's ability to operate quietly, ensuring minimal disruption in noise-sensitive environments. The manufacturer has integrated advanced sound-dampening technology, allowing businesses to maintain a comfortable atmosphere.

The system's easy installation and maintenance further enhance its appeal. The THGD series comes with a user-friendly design that simplifies access to crucial components. This accessibility reduces downtime and maintenance costs, making it a practical option for facility managers.

A key technology embedded within the York THGD18 THRU 60 series is the advanced microprocessor control system. This intelligent feature allows for precise management of the unit's functions, enabling seamless integration with building management systems. The controls also include user-friendly interfaces that facilitate real-time monitoring and adjustments.

Moreover, the unit employs eco-friendly refrigerants that comply with stringent environmental regulations. This forward-thinking approach not only aligns with global sustainability efforts but also ensures compliance with future regulatory requirements.

In summary, the York THGD18 THRU 60 series stands out for its efficient variable speed operation, robust design, user-focused features, and commitment to sustainability. With an impressive range of capacities and highly adaptable technologies, it remains a top choice for businesses seeking reliable and efficient climate control solutions.