BC2001, TR2000 specifications

The Zenoah TR2000 and BC2001 are two prominent models in the realm of outdoor power equipment, renowned for their advanced technologies and efficient performance. These products are engineered for both professional landscapers and passionate gardeners, offering a balanced blend of power, durability, and ease of use.The TR2000 is recognized for its robust engine design, incorporating a powerful two-stroke engine that delivers exceptional torque and performance. This model features an innovative air filtration system that minimizes the amount of dust and debris that enter the engine, promoting longevity and reliability. The lightweight frame enhances maneuverability, making it ideal for various applications, from trimming hedges to shaping larger topiaries.

On the other hand, the BC2001 showcases a versatile design, suitable for both grass cutting and brush clearing tasks. It is equipped with a high-efficiency cutting system that enables users to tackle dense vegetation effortlessly. The BC2001’s ergonomic handle design reduces operator fatigue, allowing prolonged usage without discomfort. Its adjustable harness ensures proper weight distribution, enhancing control and stability during operation.

Both models employ Zenoah’s signature G-Force Engine Technology, which optimizes fuel efficiency while reducing harmful emissions. This technology not only meets strict environmental regulations but also provides a cost-effective solution for users, as it minimizes fuel consumption over time.

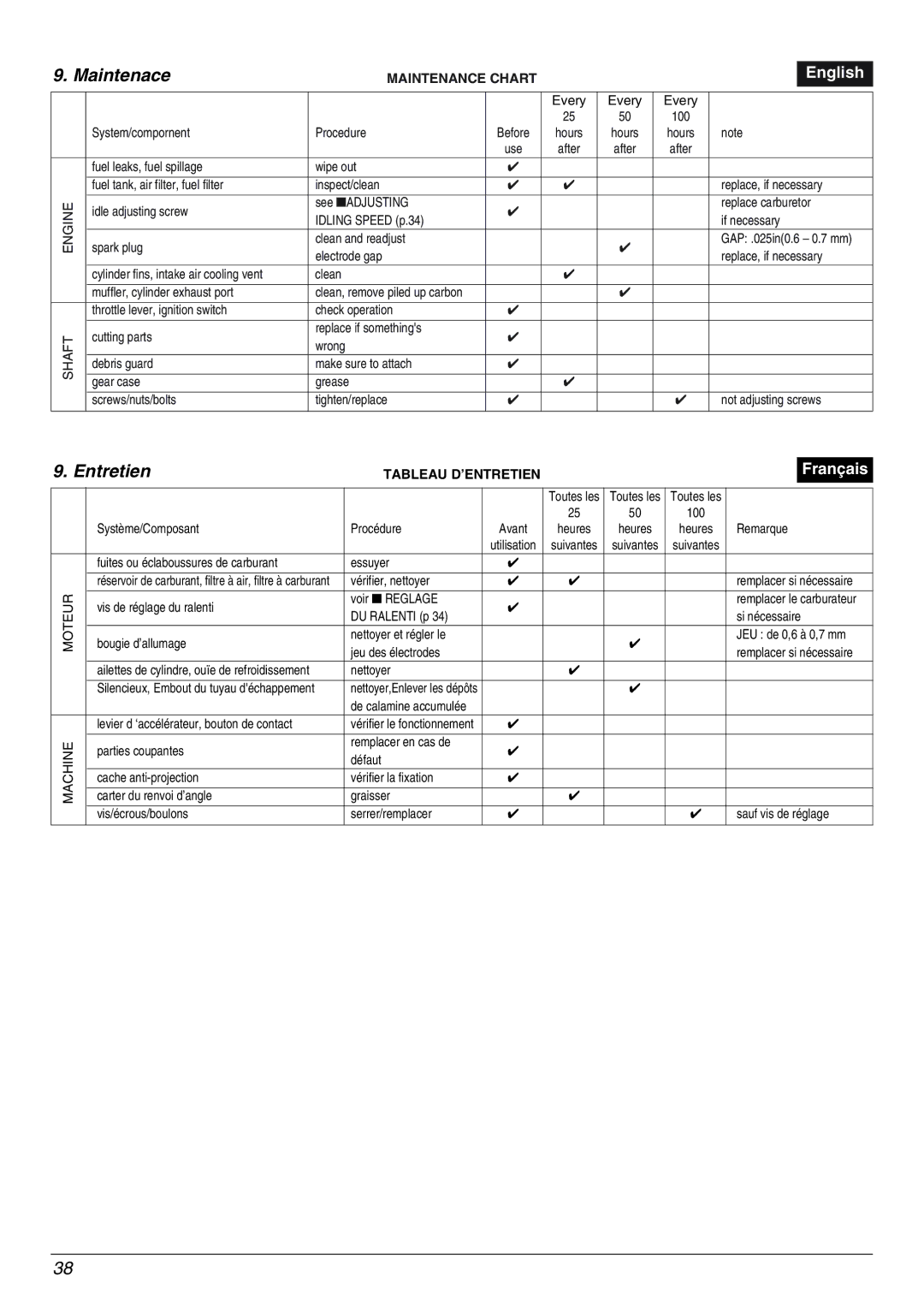

Moreover, the TR2000 and BC2001 feature an easy-start mechanism that reduces the effort needed for ignition, making them accessible for users of all skill levels. Maintenance is simplified through user-friendly designs that allow for easy access to key components, ensuring that these machines stay in prime working condition with minimal downtime.

The build quality of the Zenoah models reflects a commitment to durability, utilizing high-grade materials that endure the rigors of outdoor use. Both the TR2000 and BC2001 are backed by a solid warranty, further emphasizing Zenoah's confidence in their products.

In conclusion, the Zenoah TR2000 and BC2001 stand out in the competitive landscape of outdoor power tools. With their combination of advanced technology, ergonomic design, and robust performance, these models cater to a wide array of users seeking reliability and efficiency in their gardening and landscaping tasks. Whether tackling simple yard maintenance or complex landscaping projects, these machines are engineered to meet the demands of every user.