DR300 Operator Manual | Chapter 6 - Daily Maintenance |

|

|

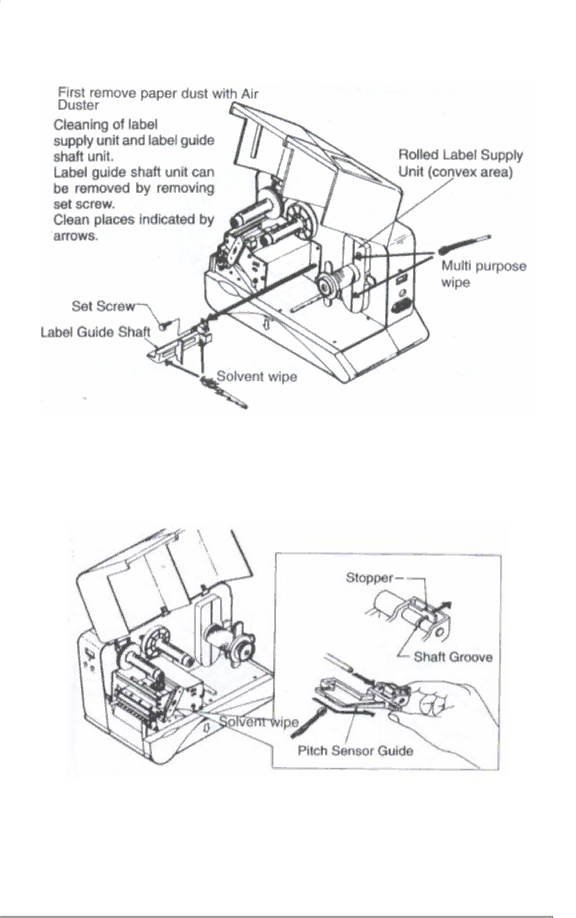

Cleaning method for printer parts

Cleaning for Pitch Sensor Unit.

Pull out Pitch Sensor Guide Unit and clean its bottom portion.

If a label is stuck, remove Pitch Sensor Guide Unit from the Shaft Groove by pulling the Stopper in the arrow direction, pull it out and clean its bottom area.

31