J-SERIESTROWEL — MAINTENANCE

3.Should the trowel arm inserts (bronze bushing ) come out with thetrowelarm,removethe bushingfromthe trowel arm andsetasideinasafeplace.Ifthebushingisretained inside the spider plate, carefully remove the bushing.

4.Examine the bronze trowel arm bushing insert (Figure 44), clean if necessary.Replace bushing if out of round or worn.

Figure 44. Bronze Bushings

Trowel Blade Removal

1.Remove the trowel blades from the trowel arm by removing thethreehexheadbolts(Figure45)fromthetrowelarm.Set blades aside.

Figure 45. Trowel Blades

2.Wirebrushany

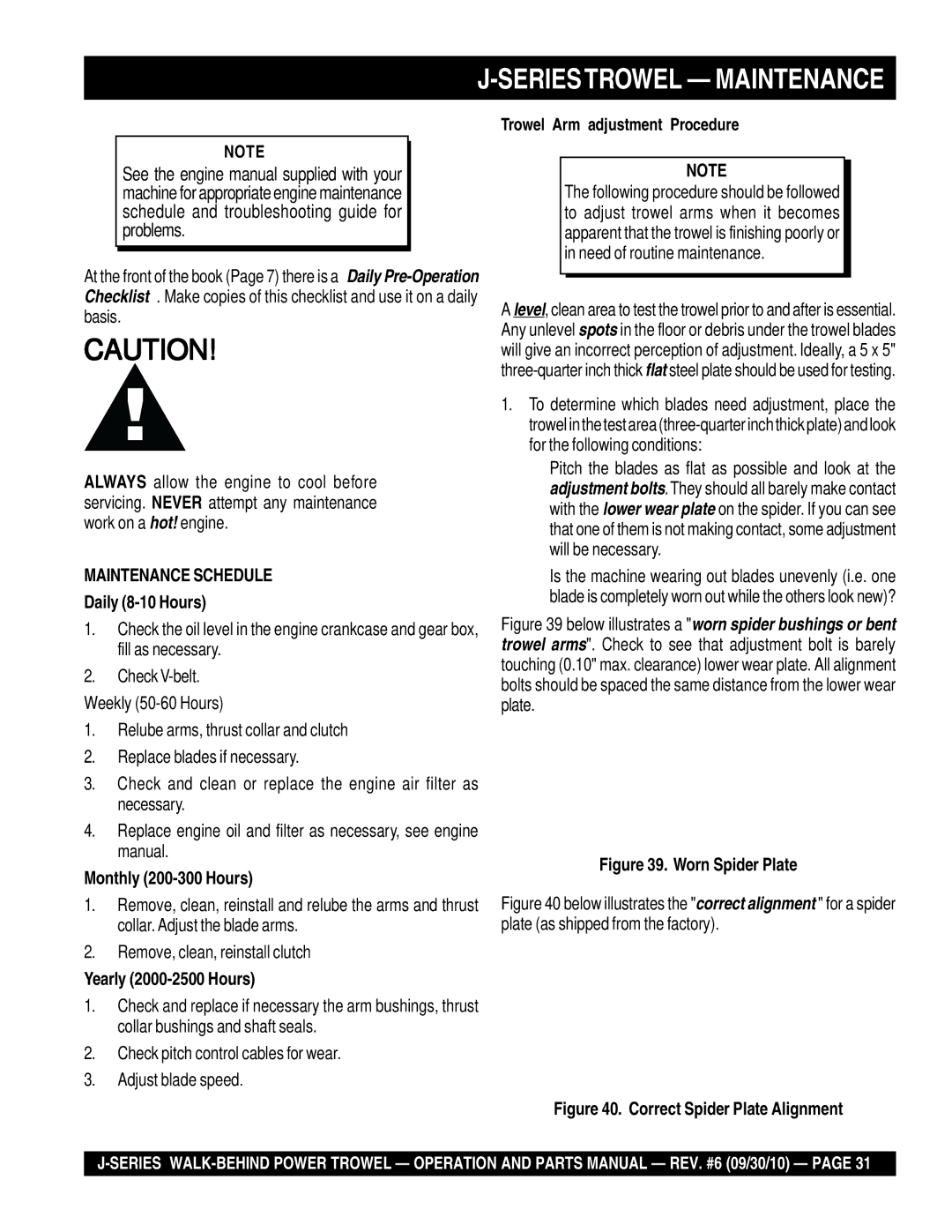

Trowel Arm Flatness Test

1.Usingapieceof3/4inchthicksteelplateoranysurfacewhich is true and flat, check all six sides of each trowel arm for flatness.

2.Check each of the six sides of the trowel arm (hex section only) using a ten thousands of an inch (max.) feeler gauge (Figure 46) between the flat of the trowel arm and an ex- tremely flat test surface.

Figure 46. Trowel Arm Flatness Test

3.If the trowel arm is found to be uneven or bent, replace the trowel arm. A bent trowel will not allow the trowel to operate in a smooth fluid rotation.

4.Next,checkeachofthesixsidesof theroundmachinedshaft sectionofthetrowelarm.Eachsectionshouldhavethesame clearance betweentheroundofthetrowelarmshaftandthe testsurface.

NOTE

Trowel arms can be damaged by rough handling or by striking exposed plumbing or forms while in operation. ALWAYS