J-SERIESTROWEL — MAINTENANCE

10.Carefully lift the upper trowel assembly, line up the key- way on gear box main shaft and insert into spider assembly

11.Reinstall square head cone point into spider plate and tighten in place.Tighten jam nut. Use care in making sure point of set screw engages groove in gear box main shaft.

12.Lubricate all grease points (zerk fittings) with premium "Lithum 12" based grease, conforming to NLG1 Grade #2 consistency.

Testing

1.Place trowel in test area, start engine and test trowel for smoothness.

2.If trowel bounces has excessive vibration or does not run smoothly repeat alignment procedure.

Changing a Blade

Whiteman recommends that all the blades be changed at the same time.The machine may wobble or bounce if only some of the blades are changed at one time.

1.Place the machine on a flat, level surface. Adjust the blade pitch control to make the blades as flat as possible. Note the blade orientation on the trowel arm.

NOTE

Before removing the blades, please note the orientation of the blade on the trowel arm.

1.Remove the three bolts and lock washers that secure the blade to the trowel arm. Remove the blade.

2.Usingawirebrush,scrapeallconcreteparticles andforeign debris from the trowel arm.

3.Install the new trowel blade onto the trowel arm. Make sure blade is installed correctly, maintaining the proper orienta- tion for direction of rotation.

4.Reinstall the three bolts and lock washers that secure the blade to the trowel arm.Tighten all three bolts securely.

5.Repeat steps

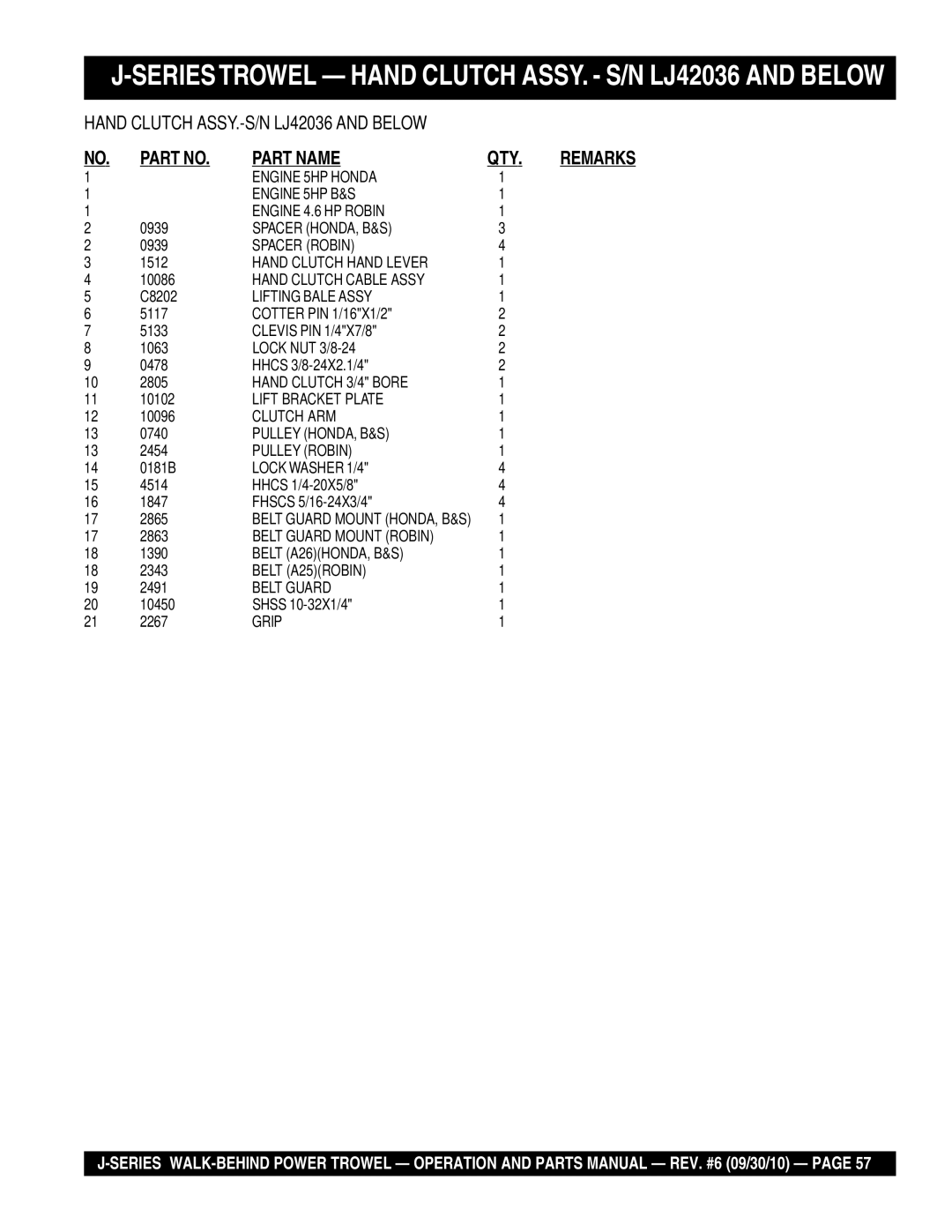

Hand Clutch Adjustment

Sometrowels are

There are two reasons to adjust the hand clutch: 1) operator comfort; 2) initial belt stretch and

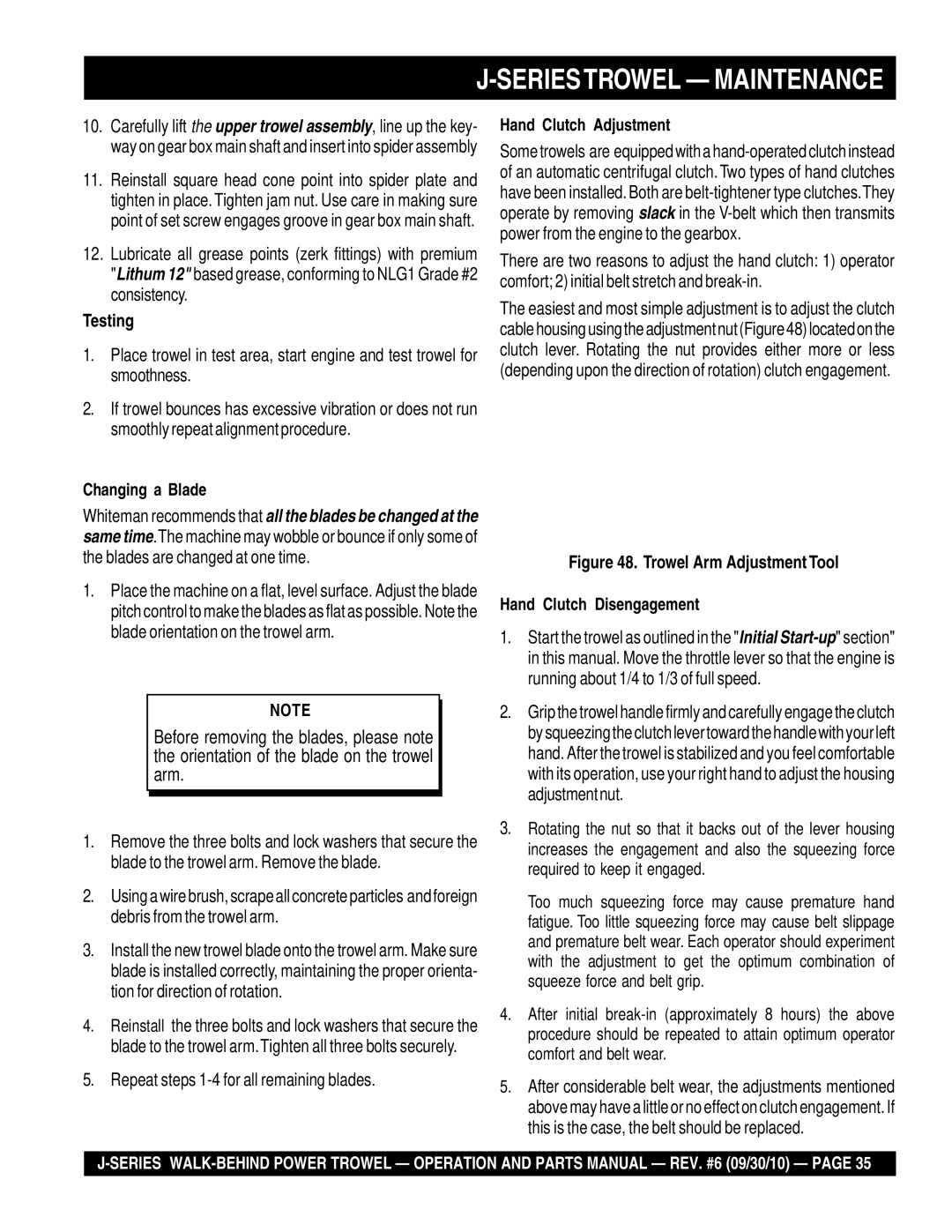

The easiest and most simple adjustment is to adjust the clutch cablehousingusingtheadjustmentnut(Figure48)locatedonthe clutch lever. Rotating the nut provides either more or less (depending upon the direction of rotation) clutch engagement.

Figure 48. Trowel Arm Adjustment Tool

Hand Clutch Disengagement

1.Start the trowel as outlined in the "Initial

2.Gripthetrowelhandlefirmlyandcarefullyengagetheclutch bysqueezingtheclutchlevertowardthehandlewithyourleft hand. After the trowel is stabilized and you feel comfortable with its operation, use your right hand to adjust the housing adjustmentnut.

3.Rotating the nut so that it backs out of the lever housing increases the engagement and also the squeezing force required to keep it engaged.

Too much squeezing force may cause premature hand fatigue. Too little squeezing force may cause belt slippage and premature belt wear. Each operator should experiment with the adjustment to get the optimum combination of squeeze force and belt grip.

4.After initial

5.After considerable belt wear, the adjustments mentioned above may have a little or no effect on clutch engagement. If this is the case, the belt should be replaced.