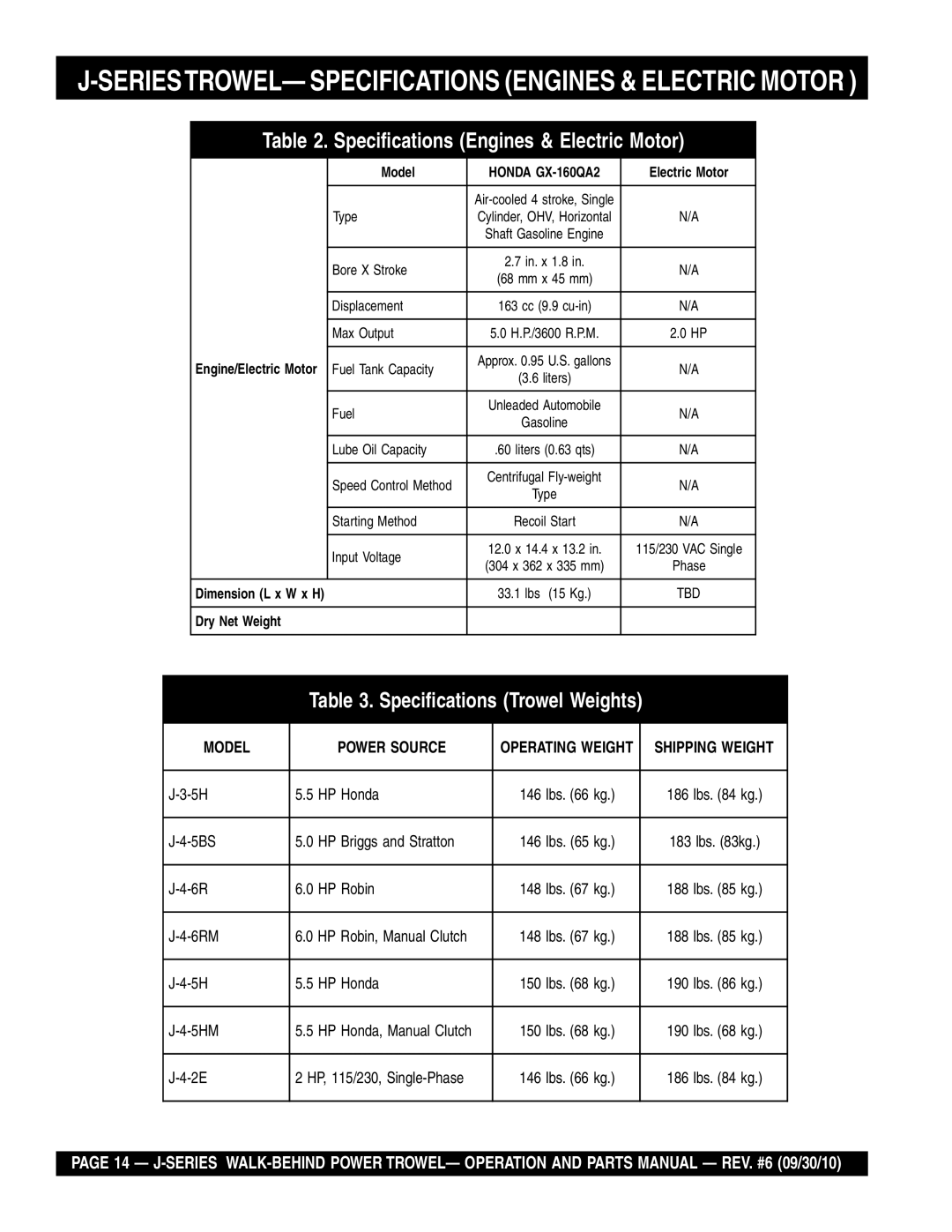

J-SERIESTROWEL— SPECIFICATIONS (TROWEL)

SideView

Figure 2. J-Series Trowel Dimensions

Table 1. J-Series Trowel Specifications

A– Height (Lifting Hook) | 36.7 in (931.6 mm) |

B– Height (Engagement Lever) | 41.4 in (1,044.2 mm) |

36.5 in. (927.1 mm) | |

70.5 in. (1,789.4 mm) | |

Weight – Operating | 150 lb. (330 kg.) |

Sound Pressure | 94 db |

Vibration | 2.0g (19.6 m/s2) |

Blade Speed (max) | 129 rpm @ 4000 |

Blade Tip Speed | 1,182 fpm (6.0 m/s) |

NOTE:

1.Sound pressure is a weighted measure. Measured at the operators ear position while the

2.The vibration level indicated is the maximum RMS (Root Mean Square) value obtained at the handle grip while operating the