J-SERIESTROWEL — MAINTENANCE

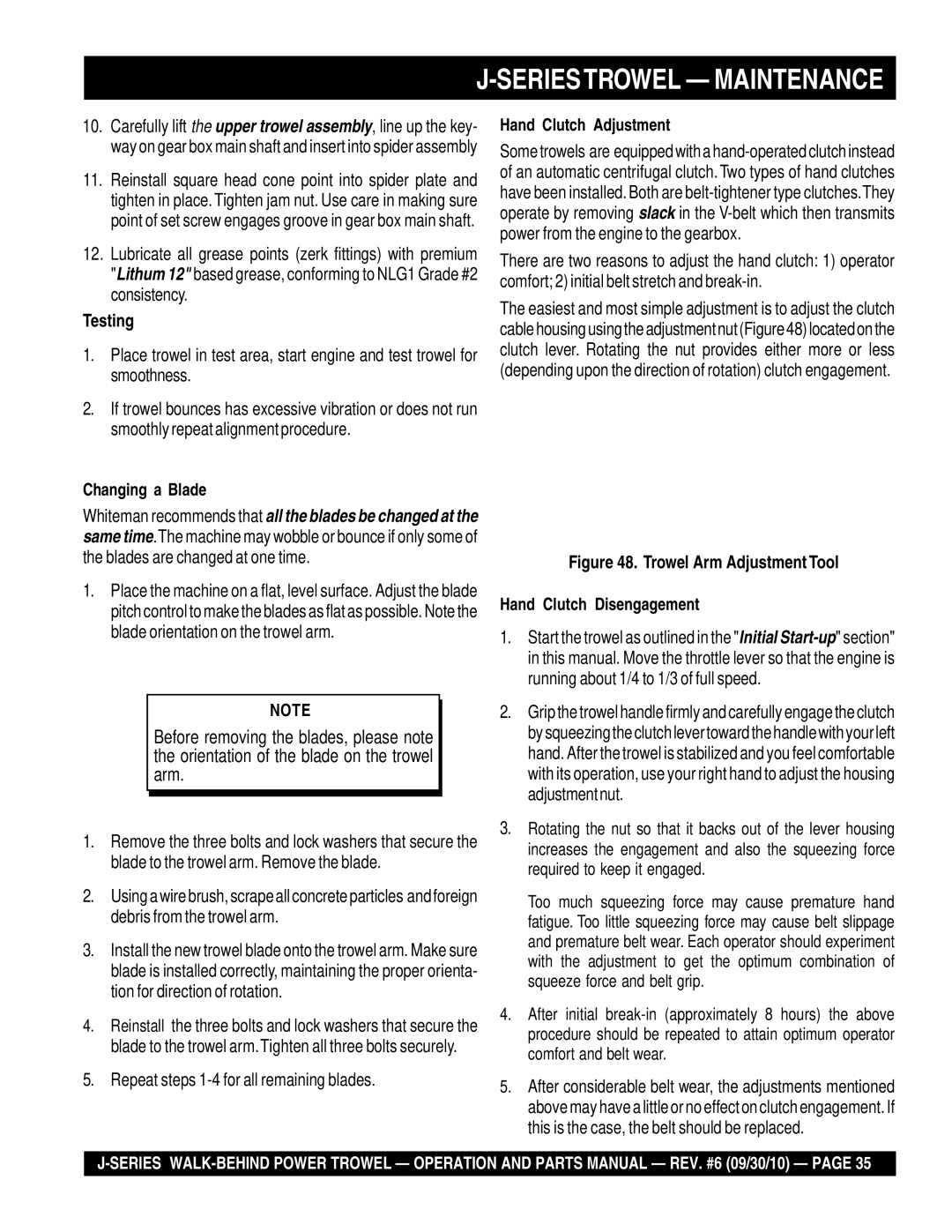

Trowel Arm Adjustment

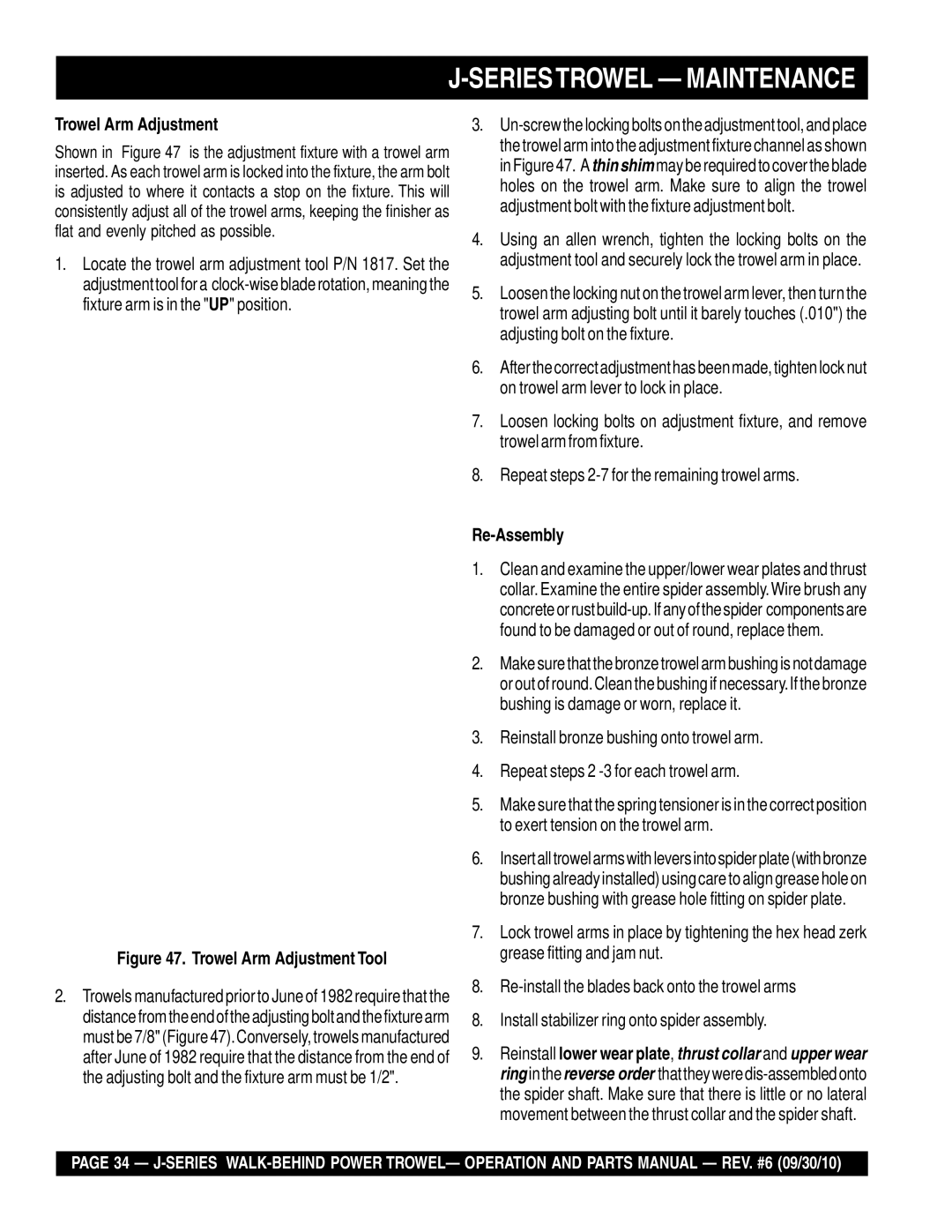

Shown in Figure 47 is the adjustment fixture with a trowel arm inserted. As each trowel arm is locked into the fixture, the arm bolt is adjusted to where it contacts a stop on the fixture. This will consistently adjust all of the trowel arms, keeping the finisher as flat and evenly pitched as possible.

1.Locate the trowel arm adjustment tool P/N 1817. Set the adjustmenttoolfora

3.

4.Using an allen wrench, tighten the locking bolts on the adjustment tool and securely lock the trowel arm in place.

5.Loosen the locking nut on the trowel arm lever, then turn the trowel arm adjusting bolt until it barely touches (.010") the adjusting bolt on the fixture.

6.Afterthecorrectadjustmenthasbeenmade,tightenlocknut on trowel arm lever to lock in place.

7.Loosen locking bolts on adjustment fixture, and remove trowel arm from fixture.

8.Repeat steps

Figure 47. Trowel Arm Adjustment Tool

2.Trowels manufactured prior to June of 1982 require that the distancefromtheendoftheadjustingboltandthefixturearm must be 7/8" (Figure 47).Conversely, trowels manufactured after June of 1982 require that the distance from the end of the adjusting bolt and the fixture arm must be 1/2".

Re-Assembly

1.Clean and examine the upper/lower wear plates and thrust collar.Examine the entire spider assembly.Wire brush any

2.Makesurethatthebronzetrowelarmbushingisnotdamage or out of round.Clean the bushing if necessary.If the bronze bushing is damage or worn, replace it.

3.Reinstall bronze bushing onto trowel arm.

4.Repeat steps 2

5.Make sure that the spring tensioner is in the correct position to exert tension on the trowel arm.

6.Insertalltrowelarmswithleversintospiderplate(withbronze bushingalreadyinstalled)usingcaretoaligngreaseholeon bronze bushing with grease hole fitting on spider plate.

7.Lock trowel arms in place by tightening the hex head zerk grease fitting and jam nut.

8.

8.Install stabilizer ring onto spider assembly.

9.Reinstall lower wear plate, thrust collar and upper wear ringinthereverse order

PAGE 34 —