J-SERIESTROWEL — OPERATION

The following steps are intended as a basic guide to machine operation, and are not to be considered a complete guide to concrete finishing. We suggest that all operators (experienced and novice) read “Slabs on Grade” published by the American Concrete Institute, Detroit, Michigan. Read the “Training” section of this manual for more information.

PitchingThe Blades.

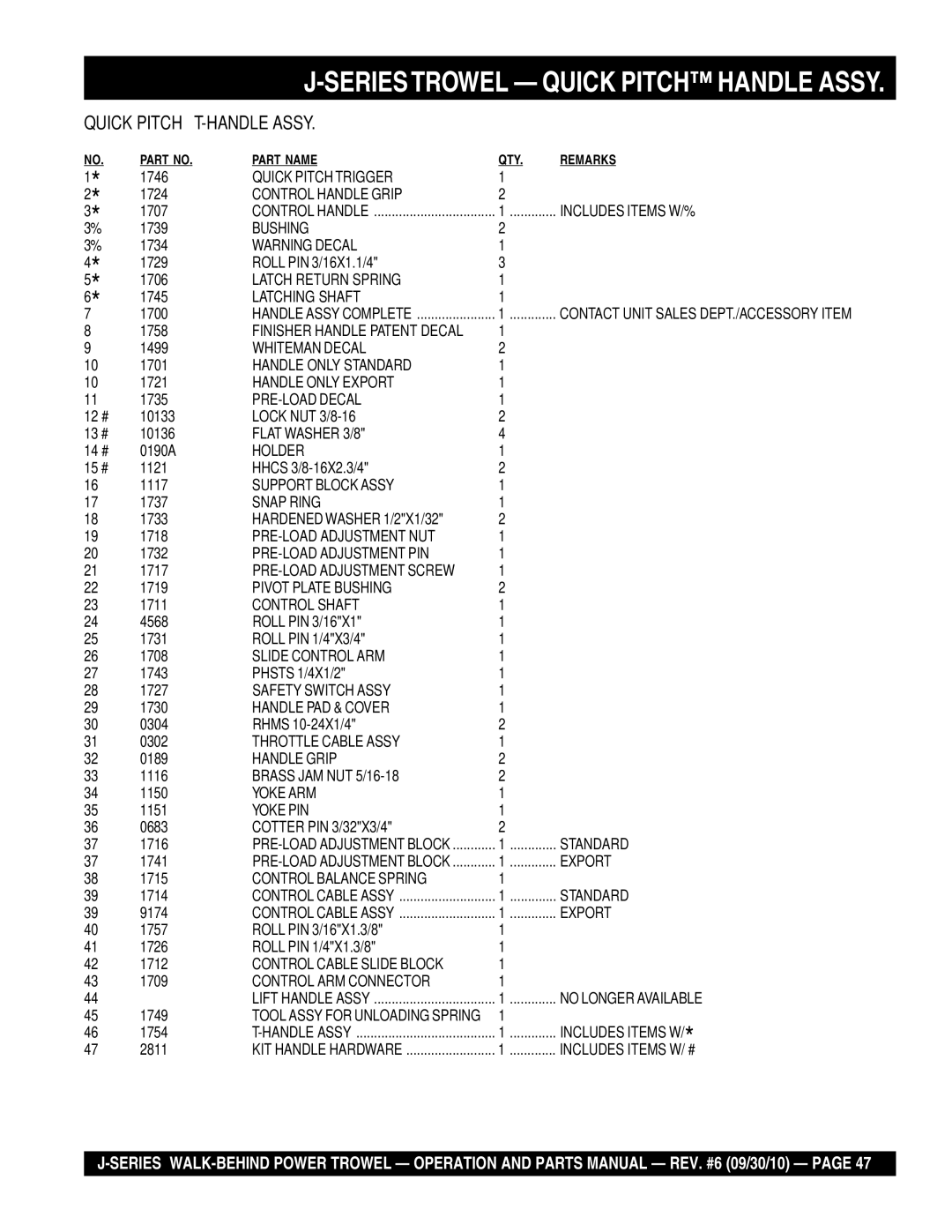

Quick Pitch Handle

1.To pitch the blades upwards using the "Quick Pitch™"

Figure 27. Quick Pitch™ T- Handle

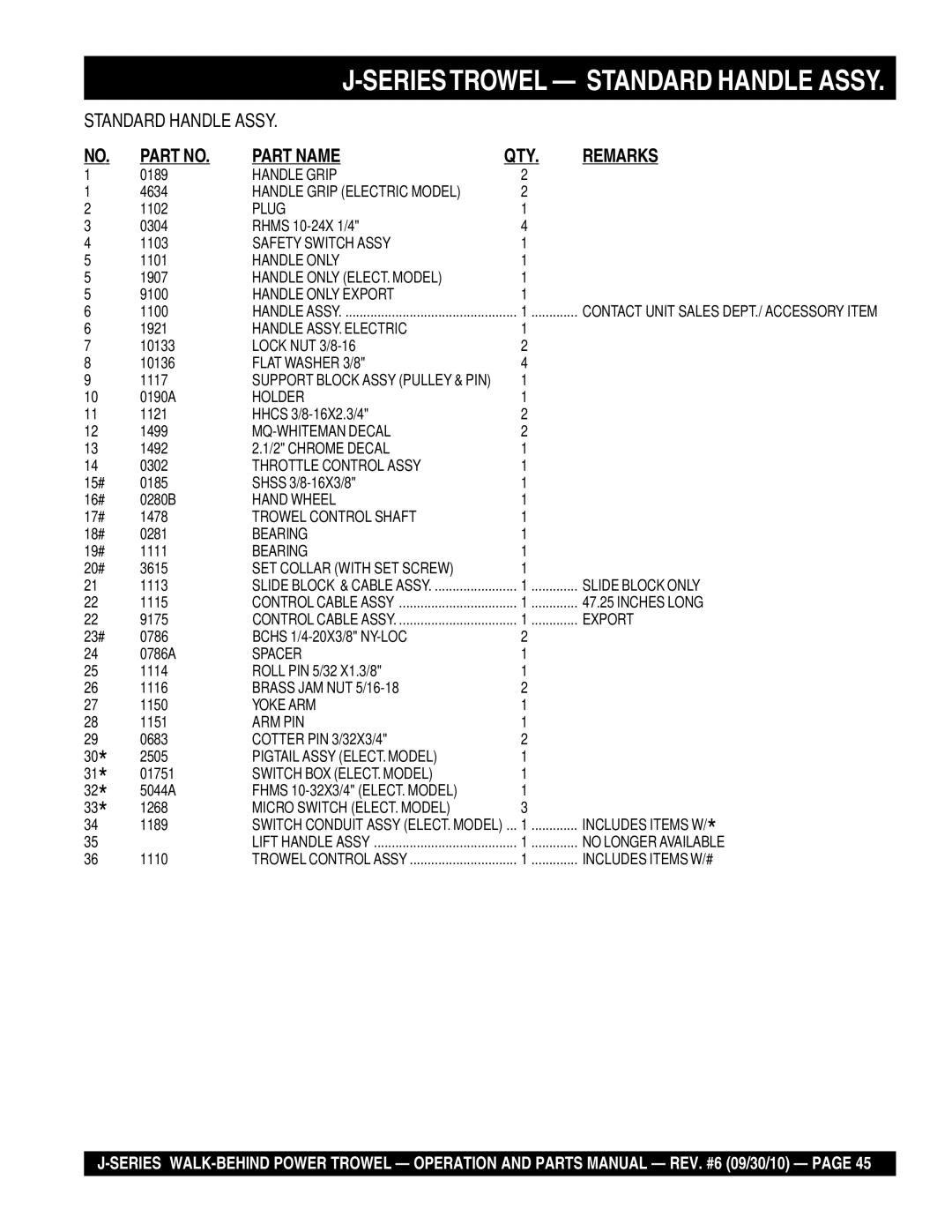

Standard Handle

1.To pitch the blades upwards using the "Standard" handle,

Figure 28. Standard Handle

Maneuvering the Trowel

1.Get into the operator’s position behind the handle. With a secure foothold and a firm grasp on the handles slowly increase the engine speed until the desired blade speed is obtained.

If your trowel has a hand clutch (Figure 29), set your engine speed with the throttle, then pull on the hand clutch lever to start the blades turning. Adjust the blade speed after the hand clutch is fully engaged.

Figure 29. Hand Clutch Lever

If your trowel has an electric motor, Squeeze the micro- switch lever ( Figure 30) to begin turning the blades. This lever will act an emergency stop switch. When this lever is released, voltage to the electric motor will be interrupted. Whenthisleverissqueezedthevoltagewillresume.Thiscan only be accomplished if the trowel's power ON/OFF switch is in the ON position.

Figure 30. Micro-Switch Engagement Lever

2.To maneuver the trowel, gently lift up on or press down on the main trowel handle. To move the machine to the operator’s left, lift up on the handle, to move machine to the right, push down on the handle.

3.The best method for finishing concrete is to slowly walk backwards (Figure 31) with the trowel, guiding the trowel from side to side.This will cover all footprints on wet concrete.

4.Remember that if you let go of the trowel, just step away and let the trowel come to a complete stop before trying to recover the trowel.