Chapter 2: Prerequisites

The

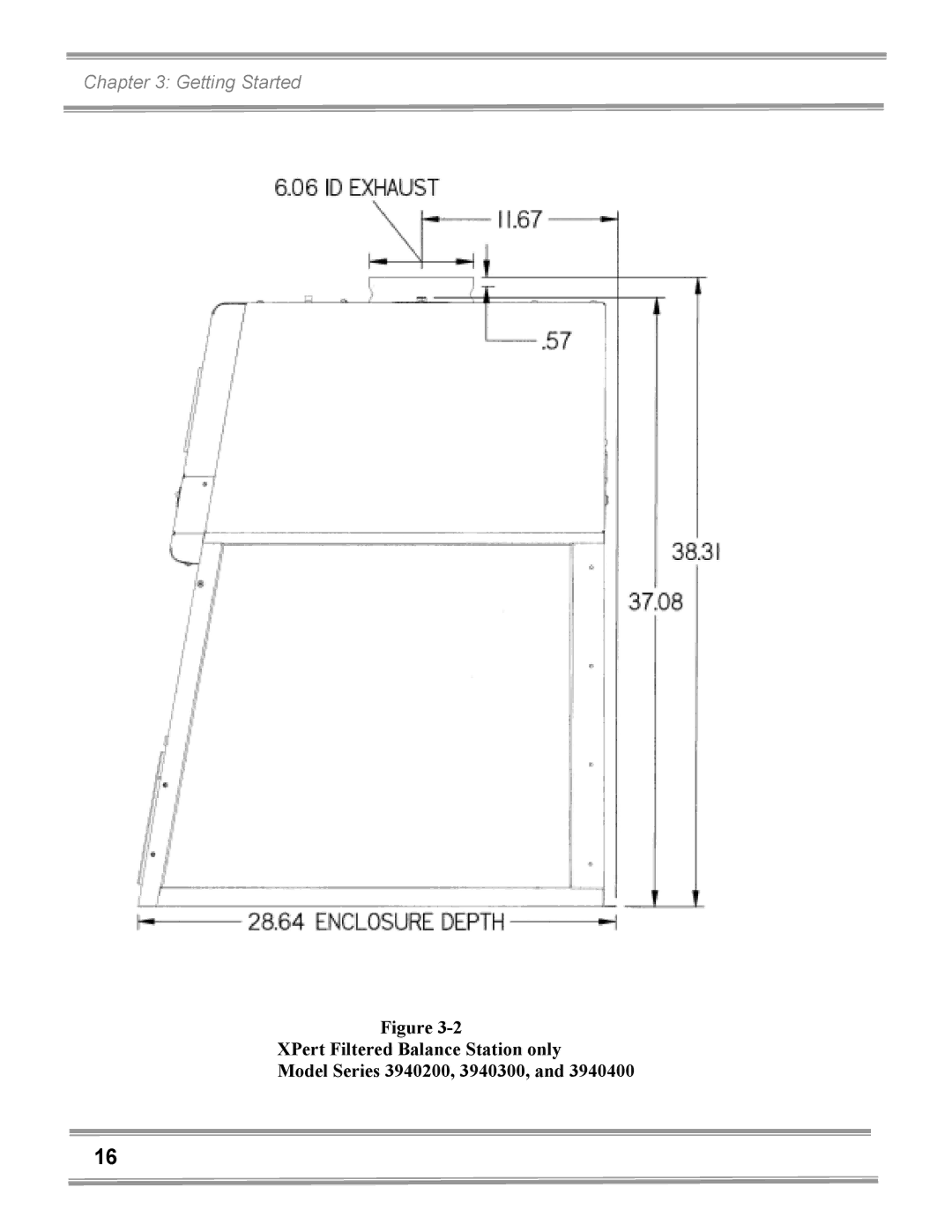

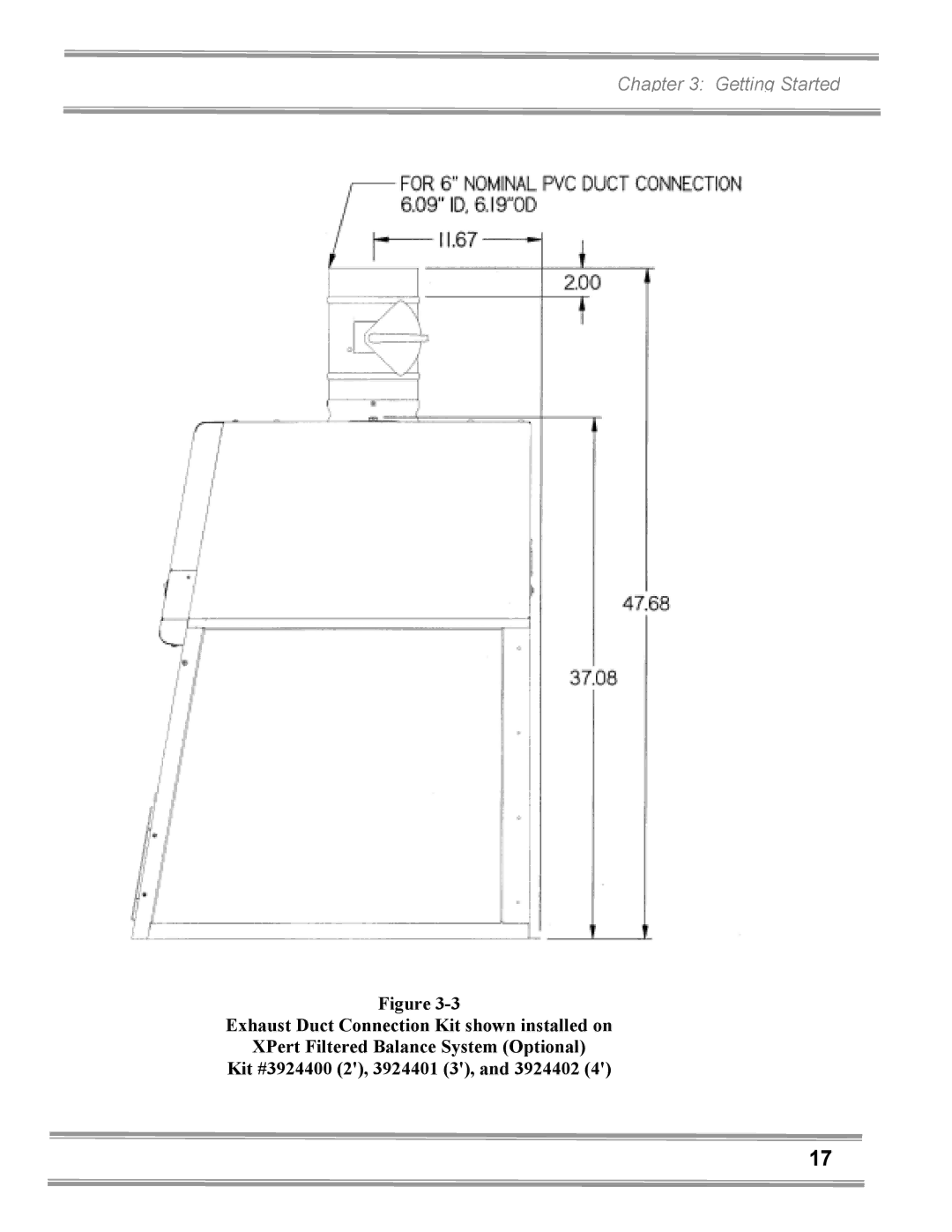

The XPert Filtered Balance Station does not include the motorized impeller and must be exhausted to the outside by a remote blower. The XPert Filtered Balance Station remote blower may be switched from the blower switch on the enclosure. See electrical Requirements in Chapter 2, and Electrical Supply Connections in Chapter 3. Only one 6" exhaust connection is required for the 2', 3', or 4' XPert Filtered Balance Stations to exhaust to the outside.

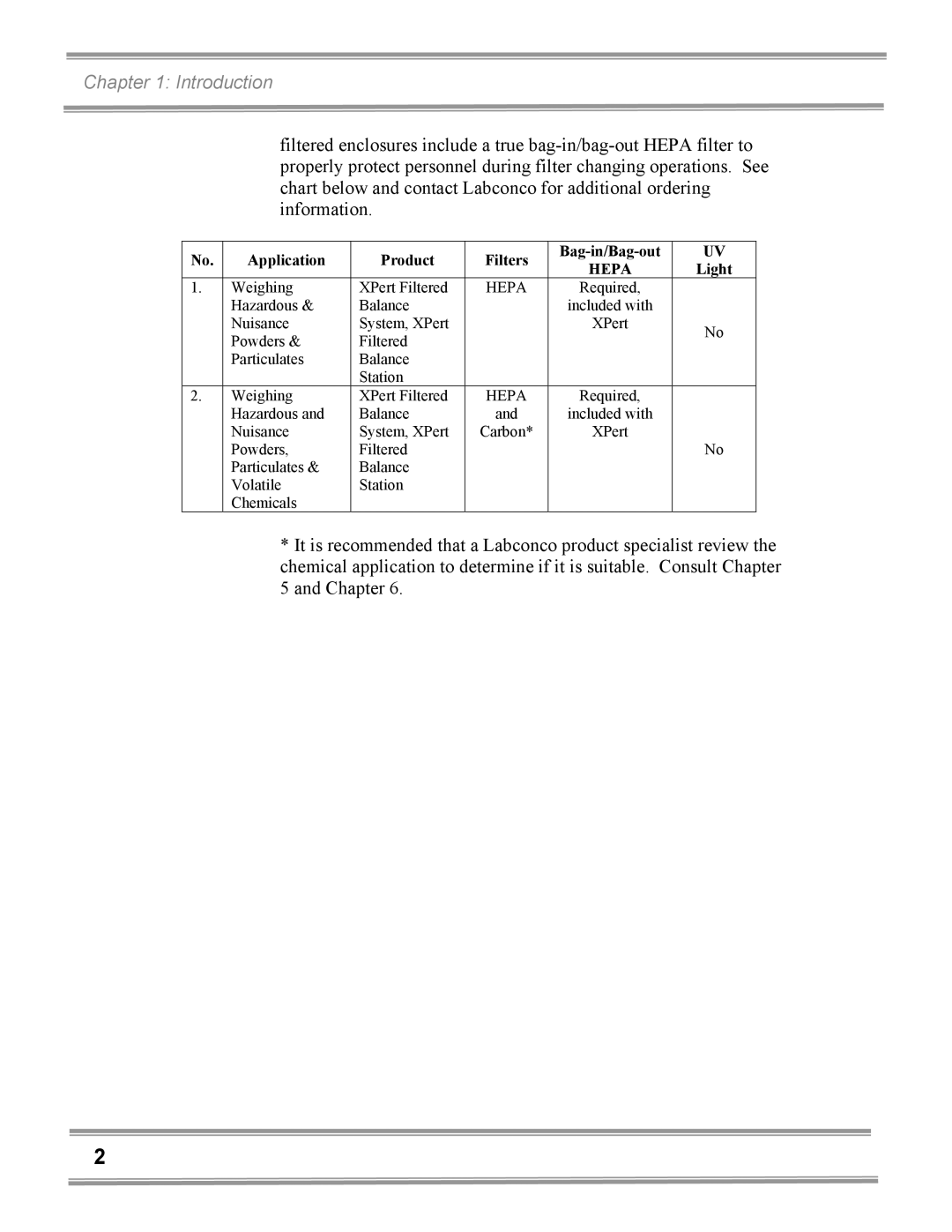

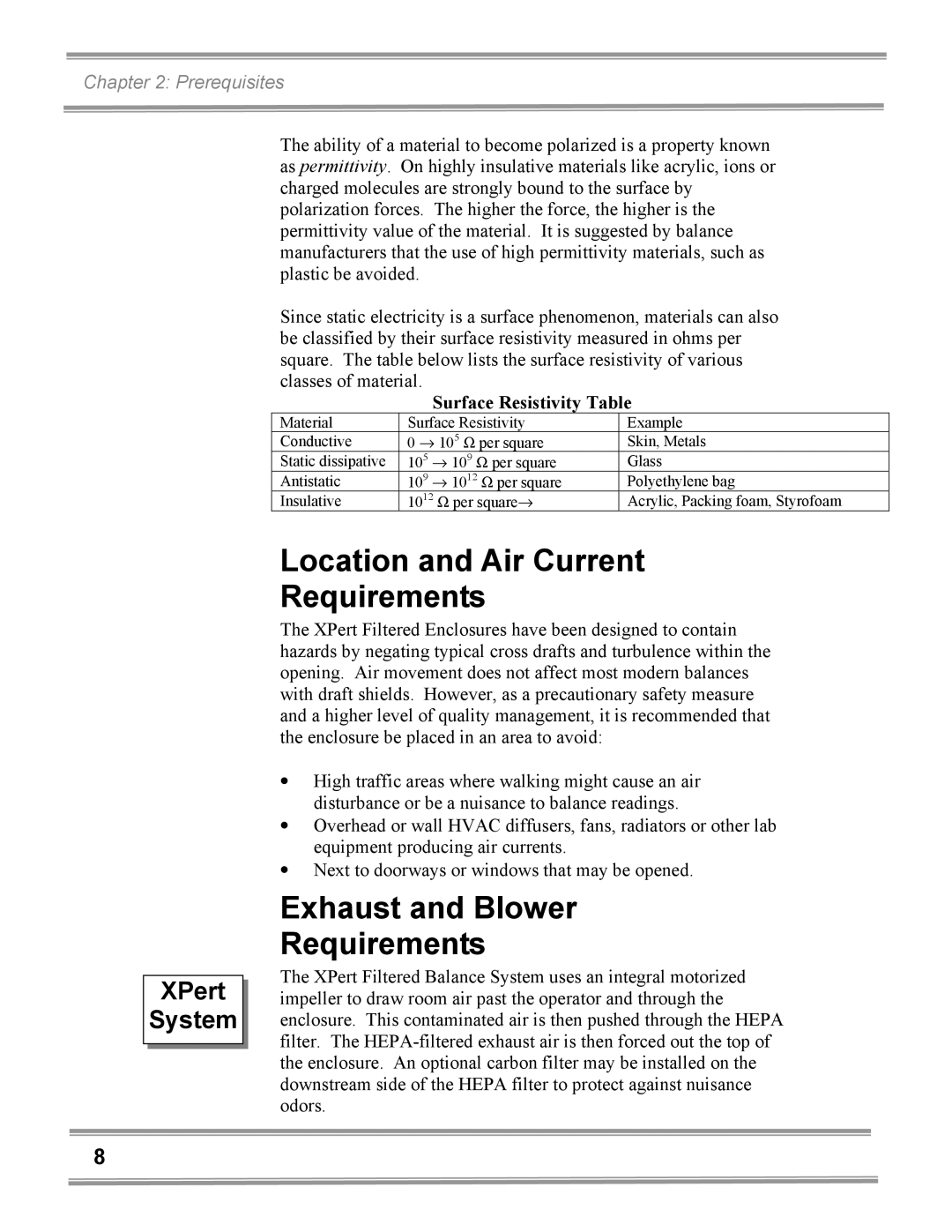

Data for the exhaust volume, noise pressure and enclosure static pressure loss are listed for each filtered enclosure model at face velocities of 60, 75, 80, 90, 100, and 105 fpm.

XPert

Station

|

|

|

| XPert |

| Xpert |

|

|

|

|

| Station |

| System | Xpert |

|

|

|

| Initial Static | XPert | Max. | System |

|

|

|

| Pressure | System | Equivalent | Max. |

|

| Face | Exhaust | Loss with | Noise | Resistance | External |

Enclosure |

| Velocity | Volume | HEPA filter | Pressure | of 6" Duct | Static |

Width | Model Description | (fpm) | (CFM) | (in w.g.) | db(A) | (Ft) | Pressure |

2' | 2' XPert Filtered Balance System | 60 | 85 | 400 | .20" | ||

| 2' XPert Filtered Balance Station | 75 | 110 | .45" | 220 | .19" | |

|

| 80 | 115 | .48" | 200 | .18" | |

|

| 90 | 130 | .56" | 140 | .16" | |

|

| 100 | 145 | .62" | 80 | .13" | |

|

| 105 | 155 | .65" | 70 | .12" | |

3' | 3' XPert Filtered Balance System | 60 | 130 | .37" | 130 | .15" | |

| 3' XPert Filtered Balance Station | 75 | 165 | .50" | 65 | .12" | |

|

| 80 | 175 | .53" | 50 | .11" | |

|

| 90 | 200 | .61" | 35 | .09" | |

|

| 100 | 220 | .68" | 25 | .08" | |

|

| 105 | 230 | .71" | 20 | .07" | |

4' | 4' XPert Filtered Balance System | 60 | 175 | .40" | 100 | .20" | |

| 4' XPert Filtered Balance Station | 75 | 220 | .53" | 60 | .19" | |

|

| 80 | 235 | .57" | 50 | .18" | |

|

| 90 | 265 | .68" | 35 | .16" | |

|

| 100 | 295 | .76" | 25 | .13" | |

|

| 105 | 310 | .80" | 20 | .12" |

9