Chapter 6: Maintaining Your Filtered Enclosure

8.If necessary, adjust the speed control of the enclosure to maintain the following airflows at 90 fpm; 2' (130cfm), 3' (200 cfm, 4' (265 cfm.)

9.Position the aerosol generator discharge in the intake of the baffle inside the enclosure.

10.Start the aerosol generator (Pressure to be +/- 1 PSIG). Ensure that one Laskin nozzle is in the “open” position.

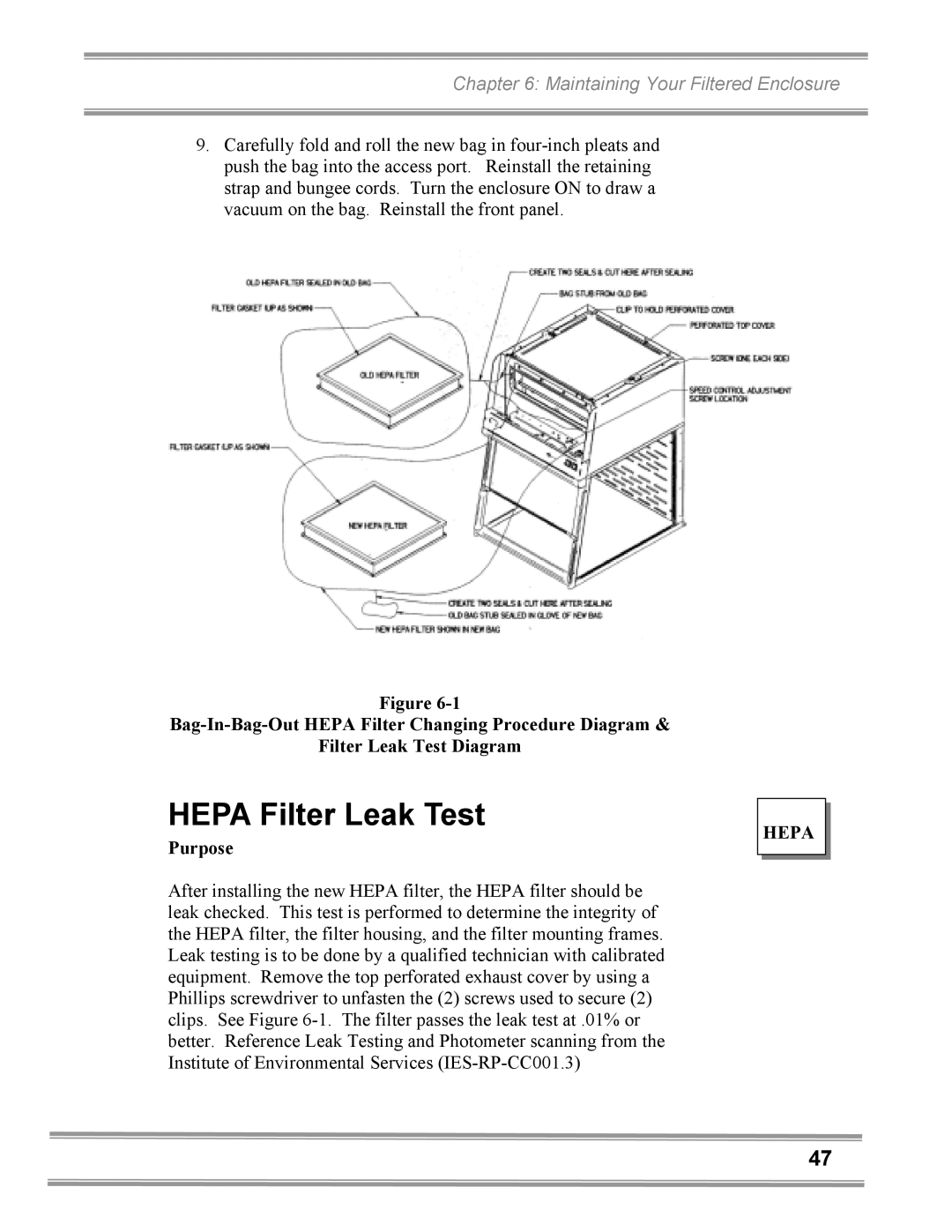

11.Allow the generator to operate for a minimum of 15 seconds. For all integral motorized impeller models, scan the downstream exhaust side of the HEPA filter by passing the sampling nozzle of the gun in slightly overlapping strokes over the entire surface the filter, with the sampling port not more than 1 inch from the surface of the filter media. Scan the entire periphery of the filter and the gasket between the filter frame and the enclosure frame. Scanning shall be done at a traverse rate of not more than 2 inches per second.

NOTE: For the XPert Filtered Balance Station, place the sampling nozzle in the center of the remote blower exhaust.

Acceptance

Aerosol penetration shall not exceed 0.01 percent measured by the photometer

Setting the Inflow Face Velocity with the Speed Control Adjustment

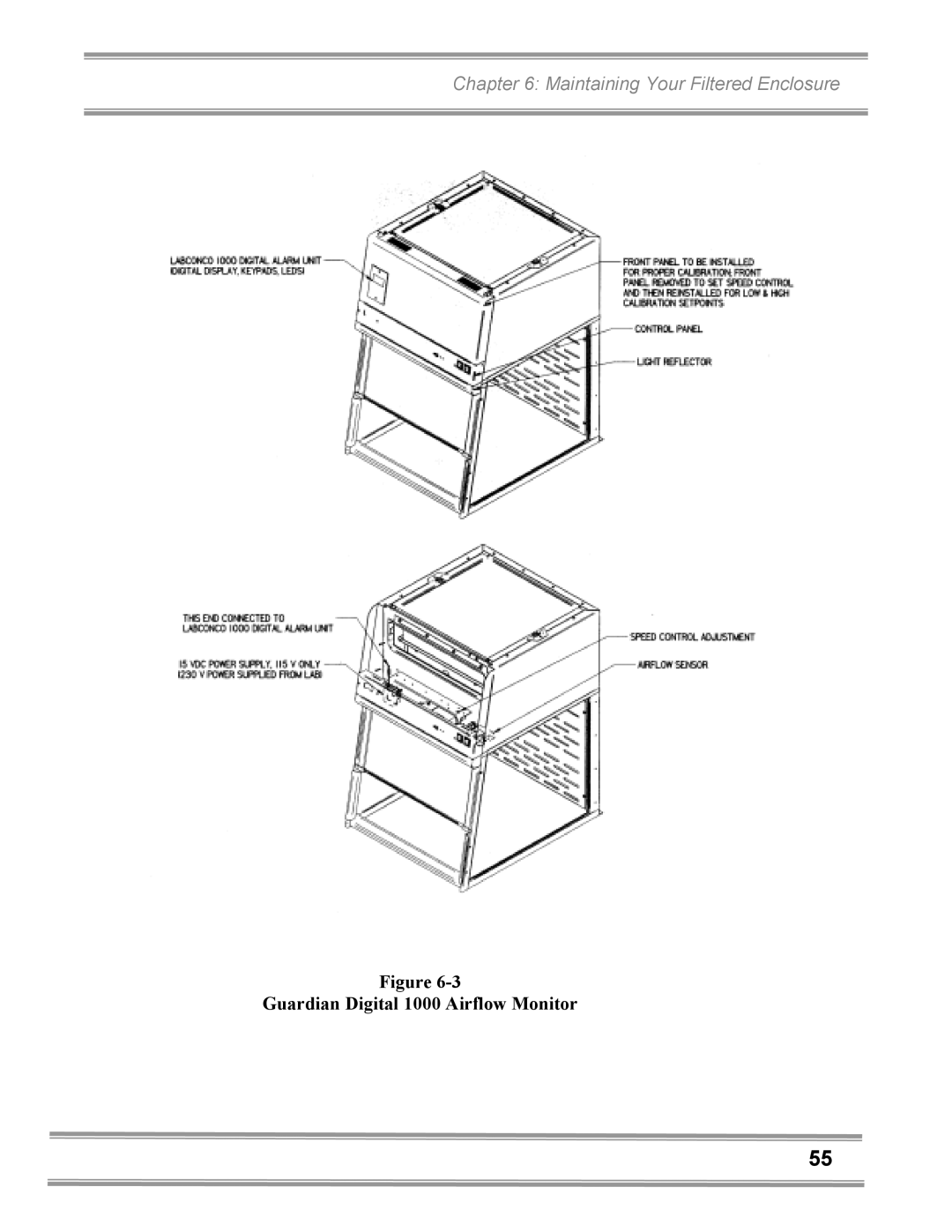

1.Remove the front panel by loosening the (2) Phillips screws on top that secure the front panel.

2.The speed control is located on the electrical subassembly located behind the switched control panel and below the front panel. See Figure

3.Adjust the speed control with a small Phillips screwdriver by turning the screw counterclockwise to increase blower speed or clockwise to decrease the blower speed. The speed control is very sensitive, so proceed with caution.

4.Measure the inflow velocity per the averaging technique outlined in Chapter 3 and adjust the speed control slowly for the desired speed. Allow the speed to stabilize and re- measure the inflow velocity to confirm.

5.Replace the front panel and tighten the screws.

XPERT

FILTERED BALANCE SYSTEM

49