SAFETY INSPECTION | PROCEDURE 2 |

This Procedure includes the following:

Safety Inspection Checklist

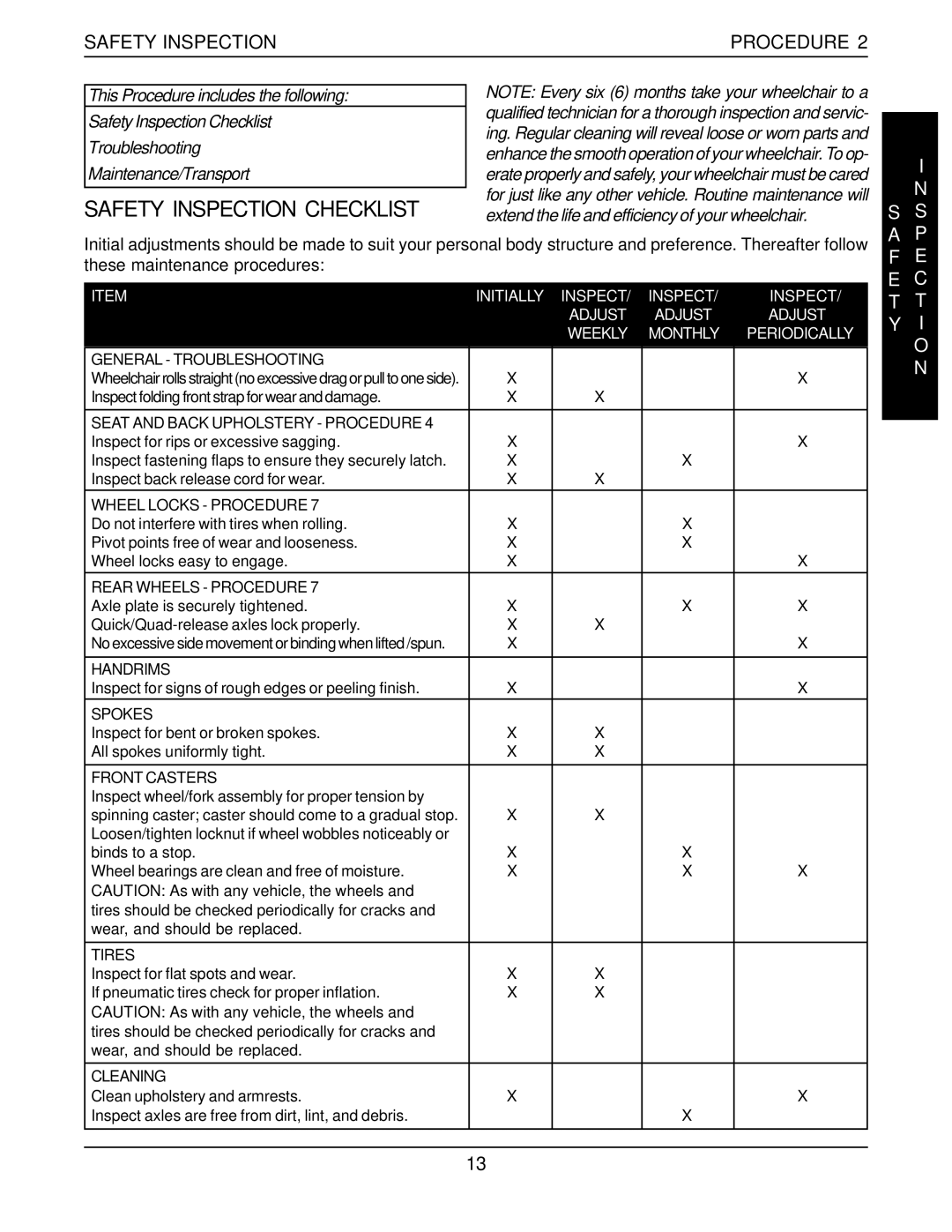

Troubleshooting

Maintenance/Transport

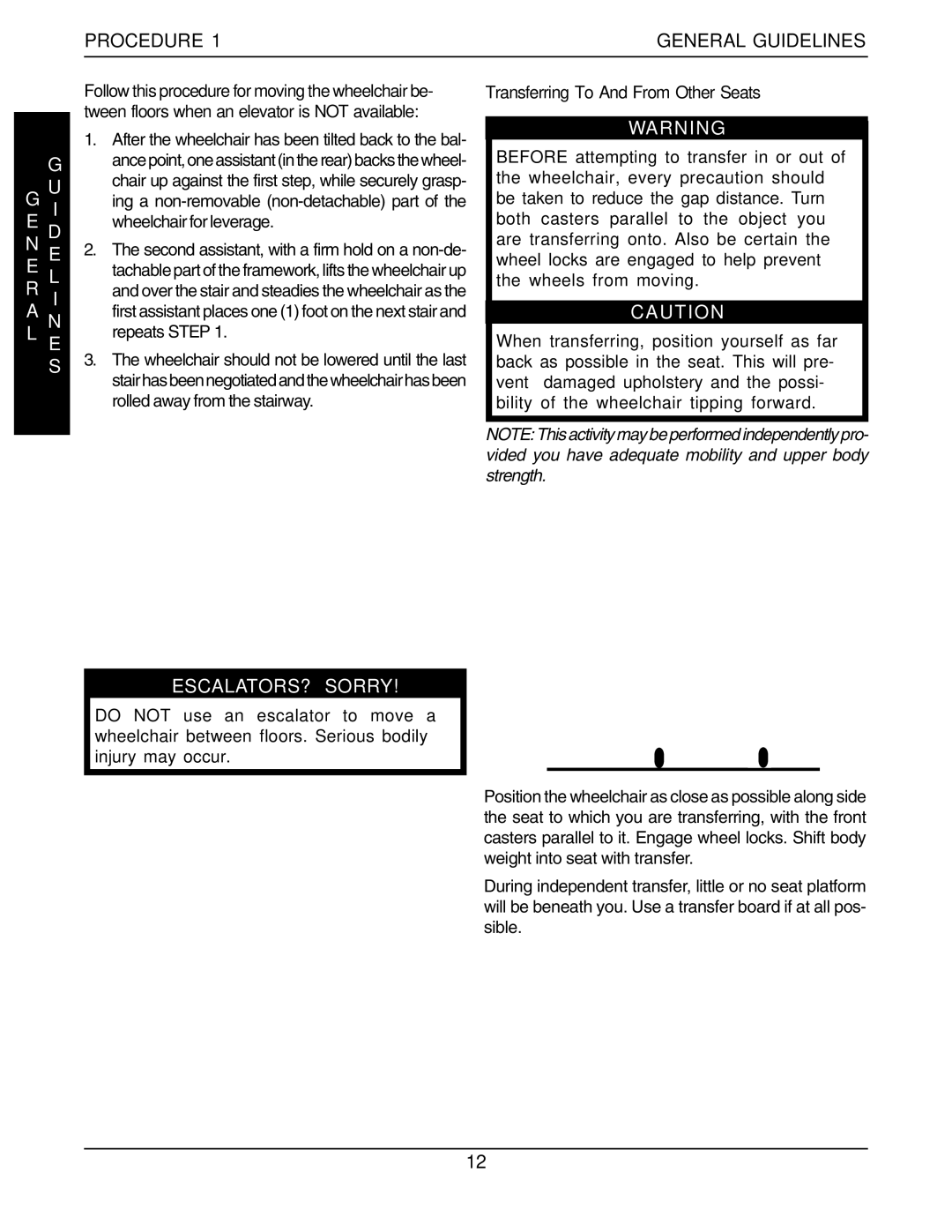

SAFETY INSPECTION CHECKLIST

NOTE: Every six (6) months take your wheelchair to a qualified technician for a thorough inspection and servic- ing. Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your wheelchair. To op- erate properly and safely, your wheelchair must be cared for just like any other vehicle. Routine maintenance will extend the life and efficiency of your wheelchair.

I

N

S S |

A P |

Initial adjustments should be made to suit your personal body structure and preference. Thereafter follow these maintenance procedures:

ITEM | INITIALLY | INSPECT/ | INSPECT/ | INSPECT/ |

|

| ADJUST | ADJUST | ADJUST |

|

| WEEKLY | MONTHLY | PERIODICALLY |

|

|

|

|

|

GENERAL - TROUBLESHOOTING |

|

|

|

|

Wheelchair rolls straight (no excessive drag or pull to one side). | X |

|

| X |

Inspect folding front strap for wear and damage. | X | X |

|

|

|

|

|

|

|

SEAT AND BACK UPHOLSTERY - PROCEDURE 4 |

|

|

|

|

Inspect for rips or excessive sagging. | X |

|

| X |

Inspect fastening flaps to ensure they securely latch. | X |

| X |

|

Inspect back release cord for wear. | X | X |

|

|

|

|

|

|

|

WHEEL LOCKS - PROCEDURE 7 |

|

|

|

|

Do not interfere with tires when rolling. | X |

| X |

|

Pivot points free of wear and looseness. | X |

| X |

|

Wheel locks easy to engage. | X |

|

| X |

|

|

|

|

|

REAR WHEELS - PROCEDURE 7 |

|

|

|

|

Axle plate is securely tightened. | X |

| X | X |

X | X |

|

| |

No excessive side movement or binding when lifted /spun. | X |

|

| X |

|

|

|

|

|

HANDRIMS |

|

|

|

|

Inspect for signs of rough edges or peeling finish. | X |

|

| X |

|

|

|

|

|

SPOKES |

|

|

|

|

Inspect for bent or broken spokes. | X | X |

|

|

All spokes uniformly tight. | X | X |

|

|

|

|

|

|

|

FRONT CASTERS |

|

|

|

|

Inspect wheel/fork assembly for proper tension by |

|

|

|

|

spinning caster; caster should come to a gradual stop. | X | X |

|

|

Loosen/tighten locknut if wheel wobbles noticeably or |

|

|

|

|

binds to a stop. | X |

| X |

|

Wheel bearings are clean and free of moisture. | X |

| X | X |

CAUTION: As with any vehicle, the wheels and |

|

|

|

|

tires should be checked periodically for cracks and |

|

|

|

|

wear, and should be replaced. |

|

|

|

|

|

|

|

|

|

TIRES |

|

|

|

|

Inspect for flat spots and wear. | X | X |

|

|

If pneumatic tires check for proper inflation. | X | X |

|

|

CAUTION: As with any vehicle, the wheels and |

|

|

|

|

tires should be checked periodically for cracks and |

|

|

|

|

wear, and should be replaced. |

|

|

|

|

|

|

|

|

|

CLEANING |

|

|

|

|

Clean upholstery and armrests. | X |

|

| X |

Inspect axles are free from dirt, lint, and debris. |

|

| X |

|

|

|

|

|

|

|

|

|

|

|

F | E |

E C | |

T | T |

Y | I |

| O |

| N |

13