![]() RANGER® 305LPG

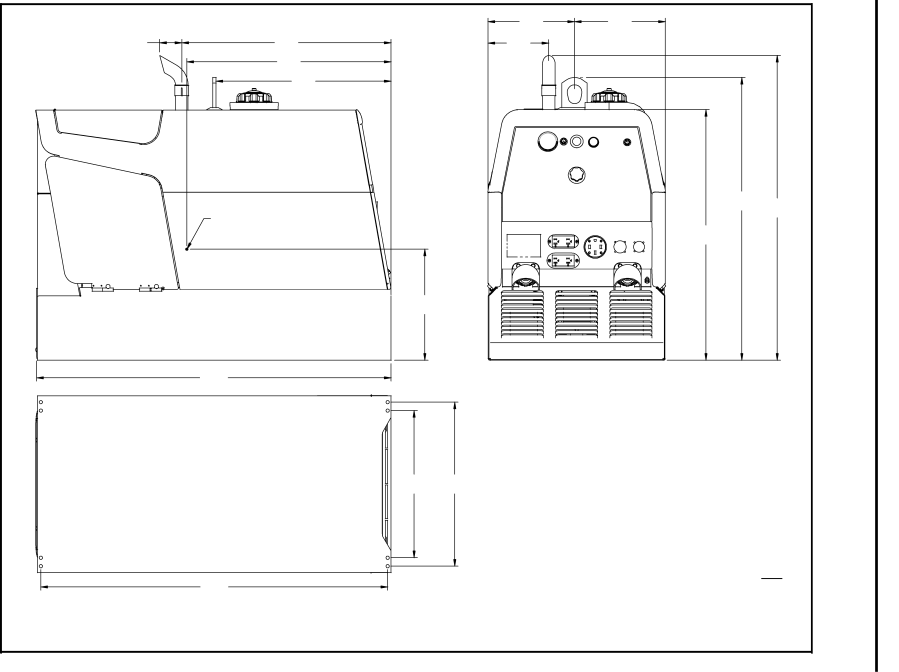

RANGER® 305LPG

|

| 10.28 | 10.78 |

| F- |

|

|

| 12 | ||

|

| 261.0 | 273.9 |

| |

2.62 | 24.86 | 7.22 |

|

| |

|

|

| |||

66.5 | 631.3 | 183.3 |

|

|

|

| 23.50 |

|

|

|

|

| 596.9 |

|

|

|

|

| 20.80 |

|

|

|

|

| 528.3 |

|

|

|

|

|

|

| 33.62 | 36.24 |

|

|

|

| 854.0 |

| |

| CENTER OF GRAVITY |

|

| 920.4 |

|

|

|

|

|

| |

|

|

| 29.80 |

|

|

|

| CIRCUIT | 756.9 |

| DIMENSION |

|

| BREAKERS |

|

| |

| 16.75 |

|

|

| |

| 425.4 |

|

|

| |

|

|

|

|

| |

| 42.10 |

|

|

| |

| 1069.5 |

|

|

| |

|

|

|

|

| |

| 17.50 | 19.50 |

|

|

|

| 444.5 | 495.3 |

|

|

|

| 41.20 |

|

| INCH |

|

|

|

| MM |

| |

| 1046.5 |

|

|

|

|

TRUCK/UNDERCARRIAGE MOUNTING HOLES |

|

|

|

| |

|

|

|

| A.01 | F |

|

|

|

| ||

|

|

|

| M22449 | |