Safety

Safety Instructions

Read and follow all safety instructions.

Personal Safety Instructions

![]() WARNING

WARNING

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemi- cals known (to the State of California) to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

•Lead from

•Crystalline silica from bricks and cement and other masonry products, and

•Arsenic and chromium from chemi- cally-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well ven- tilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

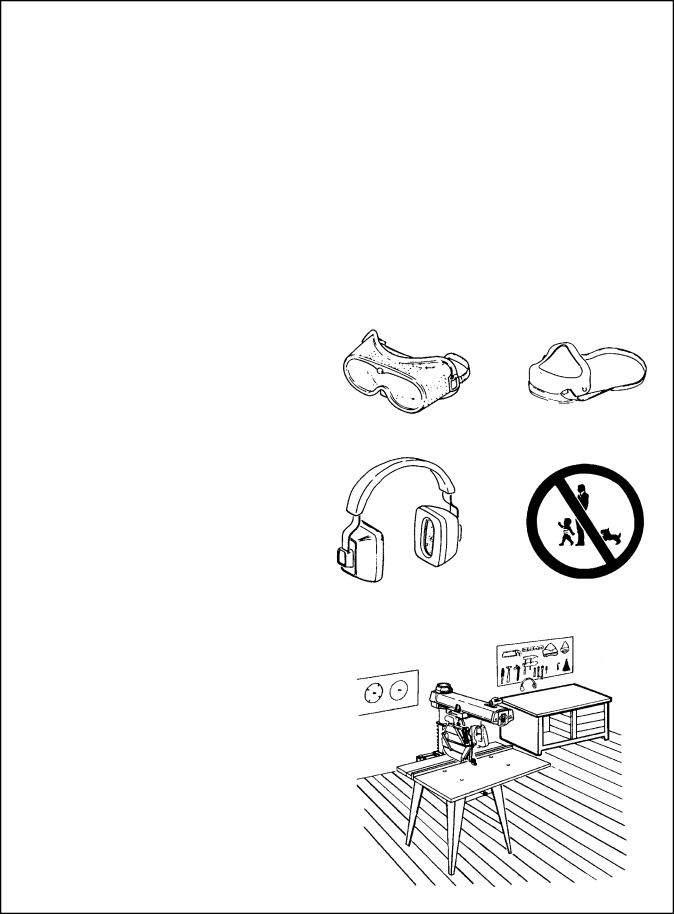

1.Wear safety goggles labeled ANSI Z87.1 (or in Canada CSA

2.Wear close fitting clothes, short sleeved shirts, and

3.Wear dust mask to keep from inhaling fine particles.

4.Wear ear protectors, plugs or muffs if you use saw daily.

5.Keep good footing and balance; do not

Work Area Safety Instructions

1.Keep children, pets, and visitors out of work area; they could be hit by a thrown workpiece, workpiece chips or pieces of blade.

2.Turn saw off, remove yellow key, and unplug before leaving work area. Do not leave until blade has stopped spinning.

3.Make work area

4.Keep floors clean and free of sawdust, wax and other slippery materials.

5.Keep work area well lighted and unclut- tered.

6.Use saw only in dry area. Do not use in wet or damp areas.

Safety Goggles | Dust Mask |

|

Ear Protectors

7