.SP6498 Belt Drive Saw 05/03 7/15/03 7:04 AM Page 43

2.Elevation Handwheel...elevates or lowers the blade. Turn clockwise to elevate, counterclockwise to lower.

3.Elevation Lock Knob...locks the blade at the desired height. To loosen, turn counterclockwise. To tighten, turn clockwise.

4Bevel Handwheel...tilts the blade for bevel cutting. Turn clockwise to tilt toward left, counterclockwise to tilt toward right.

When the blade is tilted to the left as far as it will go, it should be at 45° to the table and the bevel pointer should point 45°.

NOTE: There are limit stops inside the saw which prevent the blade from tilting beyond 45° to the left and 90° to the right. (See “Adjustments and Align- ments” section “Blade Tilt, or Square- ness of Blade to Table”).

5.Bevel Lock Handle...locks the blade in the desired tilt position. To loosen, turn counterclockwise. Push handle in and turn it to another position if necessary in order to tighten or loosen.

IMPORTANT: Be sure handle is hanging in the “DOWN” position before tilting blade. If it is pointing to the 1 o’clock position it may jam on underside of the table and bend the locking bolt.

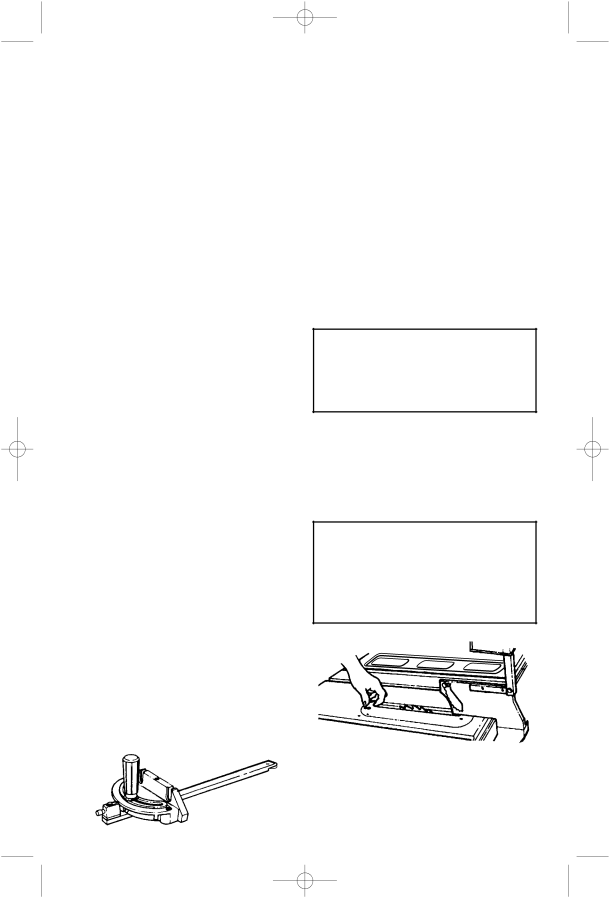

6.Rip Fence...is locked in place by pushing the lock lever down until the lever rests on the stop. To move the fence, lift the lock lever and grasp the fence with one hand at the front.

7.Miter Gauge...head is locked in position for cross cutting or mitering by tightening the lock knob. Always securely lock it when in use.

There are adjustable screw stops for the stop pin 0° and 45° right and left positions for conveniently setting the miter gauge to cut miters at these standard angles.

8.Blade Guard...must always be in place and working properly for all

To remove the guard for special operations, loosen the thumbscrew and slide the guard off the rod. Do not disturb the setting of the rod.

When replacing the guard make sure the pin in the rod engages with the notch in the spreader support. Make sure the thumbscrew is tightened securely.

9.Table Insert...is removable for removing or installing blade or other cutting tools.

WARNING: To reduce the risk of injury from accidental start, turn switch “OFF” and remove plug from power source before removing insert.

A. Lower the blade below the table surface.

B. Raise blade guard. C. Loosen insert screw.

D. Lift insert from front end, and pull toward front of saw.

WARNING: Never operate saw without the proper insert in place. Use the table insert when sawing. Use the combination dado molding insert when using a dado or molding head.

43