motor specifications Qnd eledrkai requirements

This machine is designed to use a 1725 RPM motor only. Do not use any motor that runs faster than 1725 RPM. It is

wired for operation on

current. (TOOL MUST NOT BE CONVERTED TO OPER-

ATE ON 230 VOLT EVEN THOUGH SOME OF THE

RECOMMENDED MOTORS ARE DUAL VOLTAGE,

CHANGING TO 230 VOLT WILL NOT CONSERVE

ENERGY AND REQUIRES CHANGING THE POWER CORD PLUG AND MOTOR RECEPTACLE.

THESE CRAFTSMAN MOTORS HAVE BEEN

FOUND TO BE ACCEP1ABLE FOR USE ON THIS TOOL.

HP | RPM | VOLTS | CATALOG NO. |

1/2 | 1725 | 115 | 1278 |

1/2 | 1725 | 115 | 1279 |

1/2 | 1725 | 115 | 1289 |

CAUTION: Do not use blower or washing machine motor_

or any motor with an automatic reset overload protector, as their use may be hazardous.

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded while in use to protect the operator from electric shock.

is attached to the tool housing at one end and to the ground

prong in the attachment plug at the other end.

This plug requires a mating

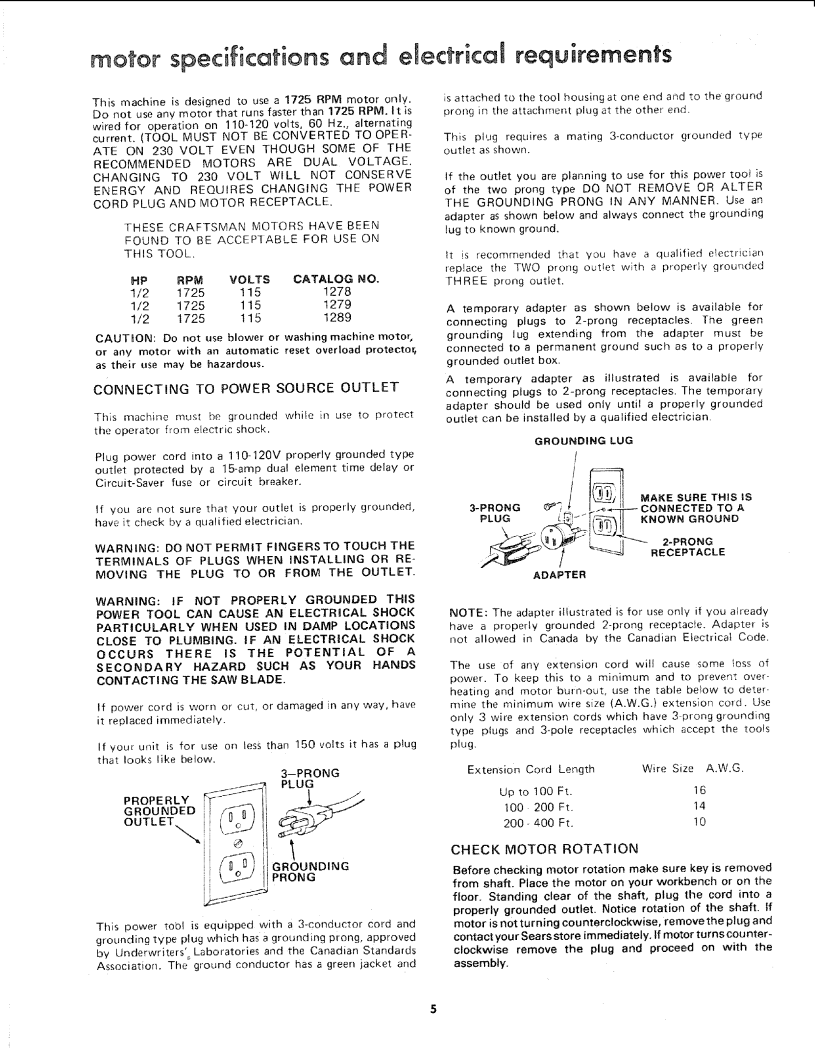

if the outlet you are planning to use for this power tool is

of the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown below and always connect the grounding _ug to known ground.

It is recommended that you have a qualified electrician rep!ace the TWO prong outlet w;th a properly grounded THREE prong outlet.

A temporary adapter as shown below is available for

connecting plugs to

grounding lug extending from the adapter must be

connected to a permanent ground such as to a properly

grounded outlet box.

A temporary adapter as illustrated is available for

connecting plugs to

GROUNDING LUG

Plug power cord into a

outlet protected by a

If you are not sure that your outlet is properly grounded, have it check by a qualified electrician.

WARNING: DO NOT PERMIT FINGERS TO TOUCH THE

TERMINALS OF PLUGS WHEN iNSTALLING OR RE-

MOVING THE PLUG TO OR FROM THE OUTLET.

|

| _ | MAKE SURE | THIS | IS |

| ,3_ | I..._""'_.,,- | CONNECTED | TO | A |

_)!_J | L_ _ |

|

|

| |

| "_ | RECEPTACLE |

| ||

| ADAPTER |

|

|

|

|

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN CAUSE AN ELECTRICAL SHOCK

PARTICULARLY WHEN USED IN DAMP LOCATIONS CLOSE TO PLUMBING. IF AN ELECTRICAL SHOCK

OCCURS THERE IS THE POTENTIAL OF A

SECONDARY HAZARD SUCH AS YOUR HANDS

CONTACTING THE SAW BLADE.

If power cord is worn or cut, or damaged in any way, have it replaced irnmediate!v.

If your unit is for use on less than 150 volts it has a plug that looks like below.

PROPERLY

GROUNDED

OUTLET,_

GROUNDING

PRONG

This power tobl is equipped with a

by Underwriters' Laboratories and the Canadian Standards

Association. The ground conductor has a green jacket and

NOTE: The adapter illustrated is for use only if you already

have a propedy grounded

not allowed in Canada by the Canadian Electrical Code.

The use | of | any | extension | cord | will | cause | some | loss | of | ||||

power. | To | keep | this | to | a minimum | and | to | prevent | over- | ||||

heating | and | motor | use | the | table | below | to | deter- | |||||

mine the | minimum | wire | size | (A.W.G.) | extension | co_d. | Use | ||||||

only 3 wire | extension | cords | which | have 3 prong | grounding | ||||||||

type plugs and

Extension | Cord | Length | Wire Size A.W.G. |

Up to | 100 | Ft. | 16 |

100 | 200 | Ft, | 14 |

Ft, | 10 | ||

CHECK MOTOR | ROTATION |

| |

Before checking motor rotation make sure key is removed

from shaft. Place the motor on your workbench or on the

floor. Standing clear of the shaft, plug the cord into a

properly grounded outlet. Notice rotation of the shaft. If

motor is not turning counterclockwise, remove the plug and

contact your Sears store immediately, tf motor turns counter-

clockwise remove the plug and proceed on with the assembly.